Method for preparing mesoporous silicon dioxide nano rod through regulation and control

A technology of mesoporous silica and nanorods, applied in silica, silica, nanotechnology and other directions, can solve the problems of complex process, heating, long reaction time, etc., to achieve short reaction time, mild reaction conditions, and preparation. Simple and easy-to-control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

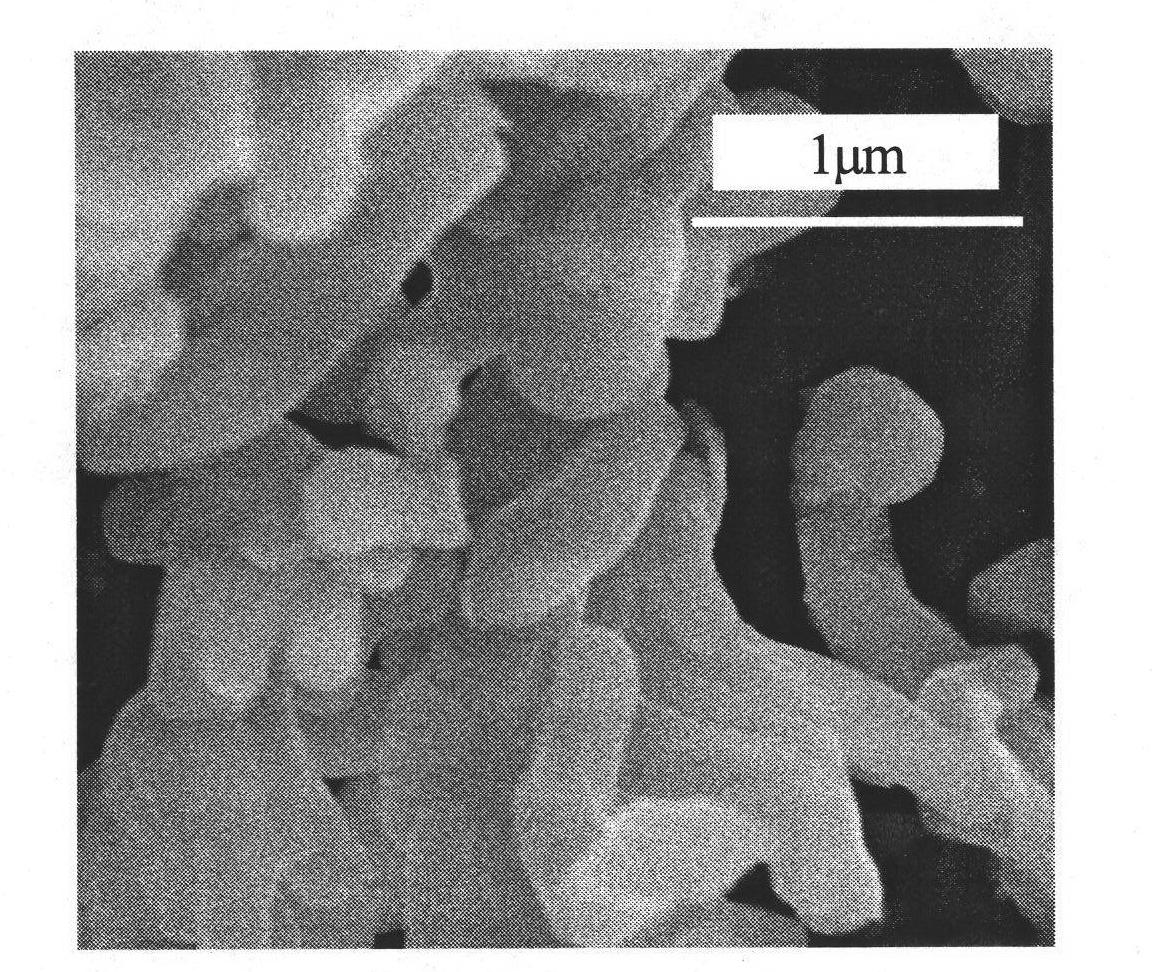

[0028] The molar ratio of ammonia water: ethanol: cetyltrimethylammonium bromide: tetraethyl orthosilicate: water is 10.4: 19.9: 0.3: 1: 371, and the mass concentration of ammonia water is 25%. The specific steps are: add ethanol, water and ammonia water into the beaker according to the ratio and mix them, and stir magnetically for 15 minutes to obtain a mixed solution; then add cetyltrimethylammonium bromide to the beaker, stir for 30 minutes until completely dissolved; cetyl trimethyl ammonium bromide After the trimethylammonium bromide is dissolved, add tetraethyl orthosilicate to the beaker, and stir for 2 hours; after the reaction, filter the reaction liquid to obtain a sample, wash the sample with distilled water for 3-5 times, then dry it at room temperature for 4 days, and then The sample was heated to 550°C at a rate of 1°C / min and calcined for 6 hours to obtain silica nanorods with a length of about 500-1200 nm, a diameter of about 250-350 nm, and a mesopore size of a...

example 2

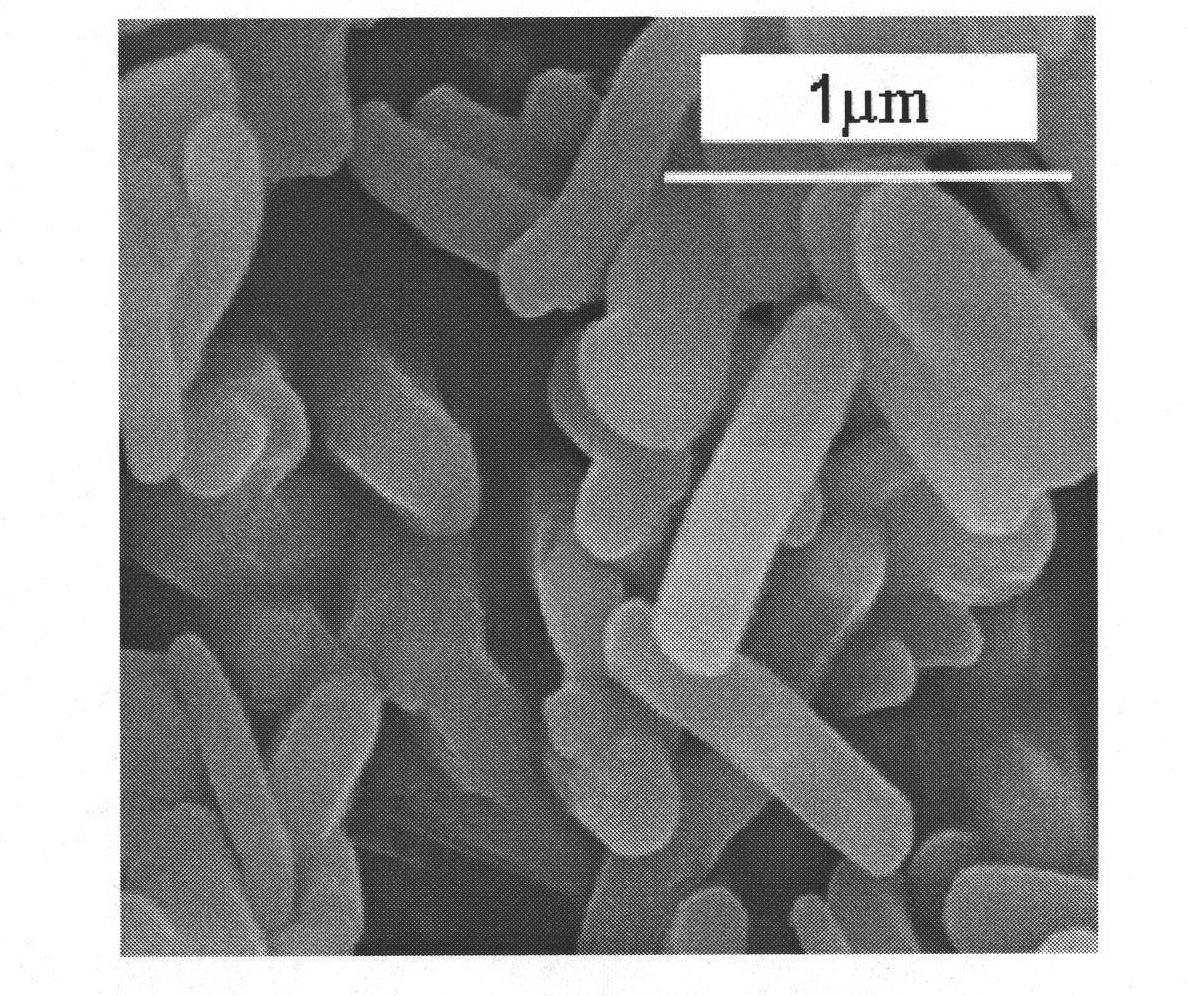

[0030] The molar ratio of ammonia water: ethanol: cetyltrimethylammonium bromide: tetraethylorthosilicate: water is 3.4:4.4:0.5:1:619, and the mass concentration of ammonia water is 25%. The specific steps are: add ethanol, water and ammonia water into the beaker according to the ratio and mix them, and stir magnetically for 30 minutes to obtain a mixed solution; then add cetyltrimethylammonium bromide to the beaker, stir for 30 minutes until completely dissolved; cetyl trimethylammonium bromide After trimethylammonium bromide is dissolved, add tetraethyl orthosilicate to the beaker, and stir for 3 hours; after the reaction, filter the reaction solution to obtain a sample, wash the sample with distilled water for 3-5 times, then dry it at room temperature for 5 days, and then The sample was heated to 550°C at a rate of 1°C / min and calcined for 6 hours to obtain silica nanorods with a length of about 900 nm, a diameter of about 200 nm, and a mesopore size of about 2.66 nm, see ...

example 3

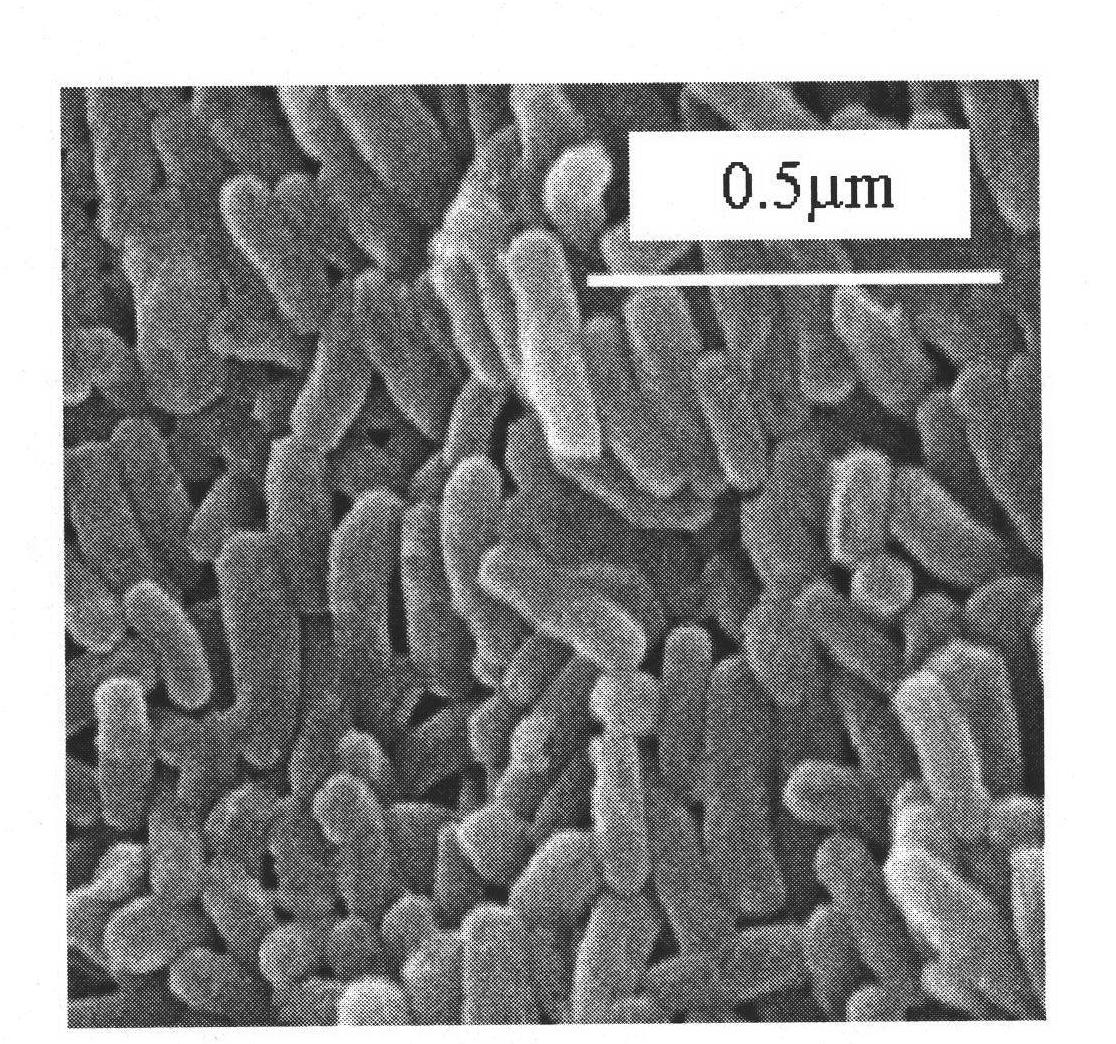

[0032] The molar ratio of ammonia water: ethanol: cetyltrimethylammonium bromide: orthosilicate ethyl ester: water is 3.4:4.4:0.5:1:1486, and the mass concentration of ammonia water is 25%. The specific steps are: add ethanol, water and ammonia water into the beaker according to the ratio and mix them, and stir magnetically for 20 minutes to obtain a mixed solution; then add cetyltrimethylammonium bromide to the beaker, stir for 20 minutes until completely dissolved; cetyl trimethyl ammonium bromide After the trimethylammonium bromide is dissolved, add tetraethyl orthosilicate to the beaker, and stir for 2 hours; after the reaction, filter the reaction liquid to obtain a sample, wash the sample with distilled water for 3-5 times, then dry it at room temperature for 7 days, and then The sample was heated to 550°C at a rate of 1°C / min and calcined for 6h to obtain silica nanorods with a length of about 100-250 nm, a diameter of about 60 nm, and a mesopore size of about 2.85 nm, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Mesopore size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com