Method for preparing prosthesis with tantalum coating

An artificial prosthesis and tantalum coating technology are applied in the field of biomedical composite materials to achieve good biocompatibility, high bonding strength, and increased bone ingrowth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

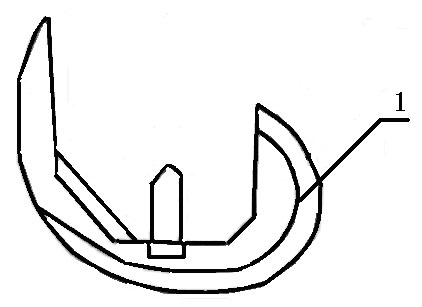

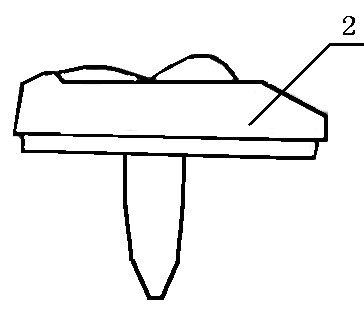

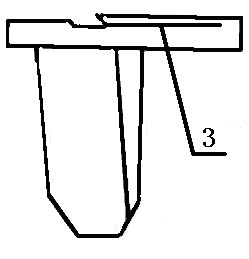

[0031] Such as Figure 1-3 As shown, the tantalum-coated artificial knee prosthesis is composed of femoral condyle component 1, tibial pad component 2, tibial tray component 3 and patella component (not shown). The above components are used together, and femoral condyle component 1 is installed on At the distal end of the femur, tibial pad component 2 and tibial tray 3 are fitted and placed on the tibial plateau, and the patella component fits with the osteotomized human patella; femoral condyle component 1, tibial tray component 3, tibial pad component 2 and the patella After the component is reset, the surrounding ligament and tendon tissue are reset and sutured for fixation. Femoral condyle component 1 and tibial tray component 3 are made of titanium alloy (Ti-6Al-4V) or cobalt-chromium-molybdenum alloy (Co30Cr6Mo0.35C), and the patella component is made of high molecular polyethylene material. Hard Al 2 o 3 Or SiC sand is used as a medium to perform sandblasting pretrea...

Embodiment 2

[0039] Such as Figure 6 , 7 As shown, the hip joint prosthesis includes a stem body 7, a stem neck 8, a femoral ball head 11 and an acetabular part; the upper end of the stem body 7 is a stem neck 8 which plays a connecting role, and the stem neck 8 is sleeved with a femoral ball The head 11, the femoral ball head 11 is sleeved with the acetabulum, and the handle body 7 is a cylinder or a cone. The inner side extends in a circular arc and extends to the handle neck 8, and the outer side of the handle body 7 is straight or arc-shaped and meets the basal outer side of the handle neck 8 to form an angular body of 80-110°. The part where the outer surface of the handle body 7 is wrapped with the tantalum surface 6 is the upper part of the handle body 7 or the outer surface of any part of the handle body 7 . The tantalum surface 6 wrapped by the handle body 7 is a microporous structure, and the thickness of the tantalum surface 6 is 200 , The microporosity is 40%.

[0040] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com