Method for electrochemically preparing peroxysulfuric acid

An electrochemical, monosulfuric acid technology, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of no successful synthesis, difficult to produce hydrogen peroxide, etc., and achieve the effects of high energy, easy operation and short action time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

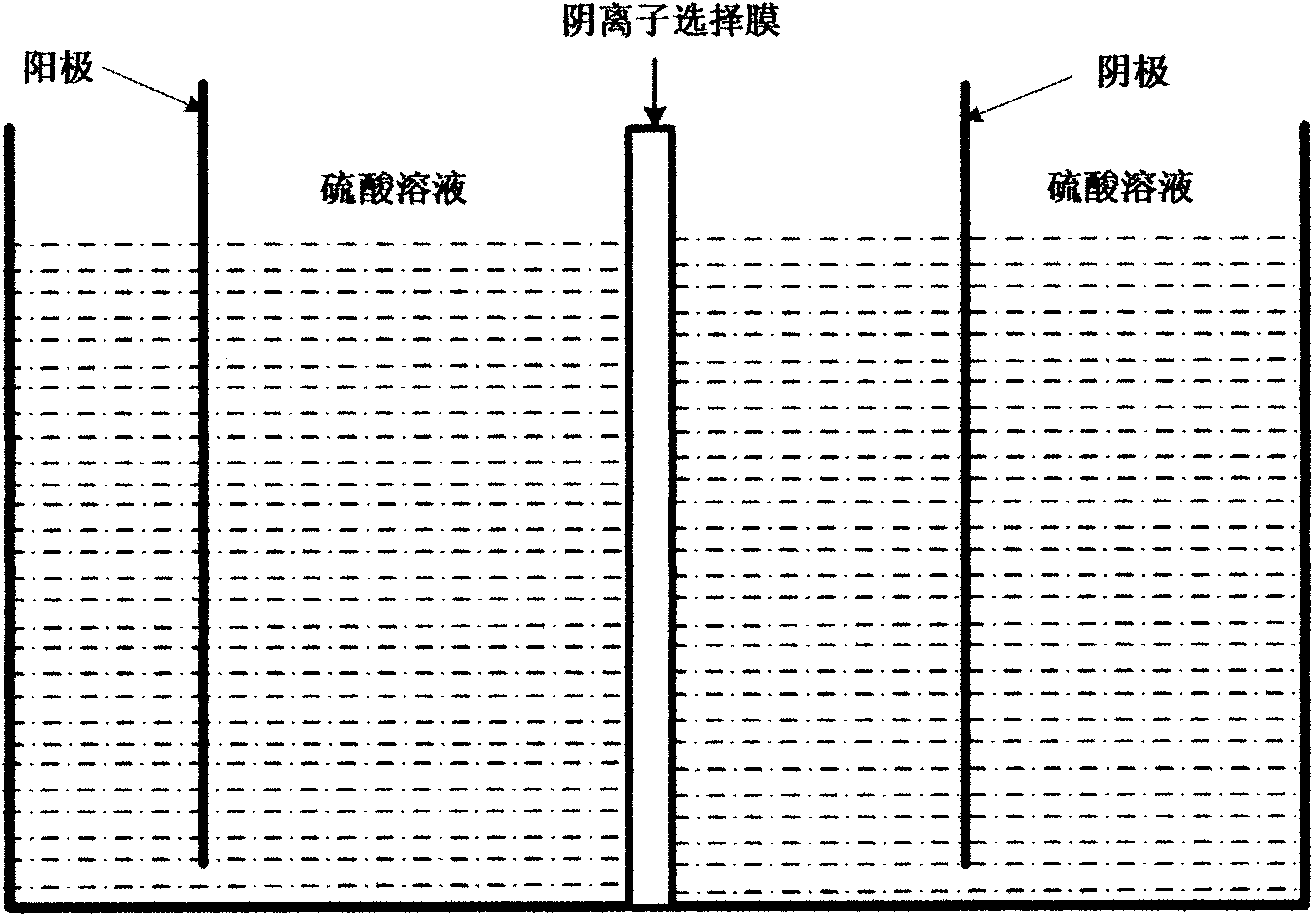

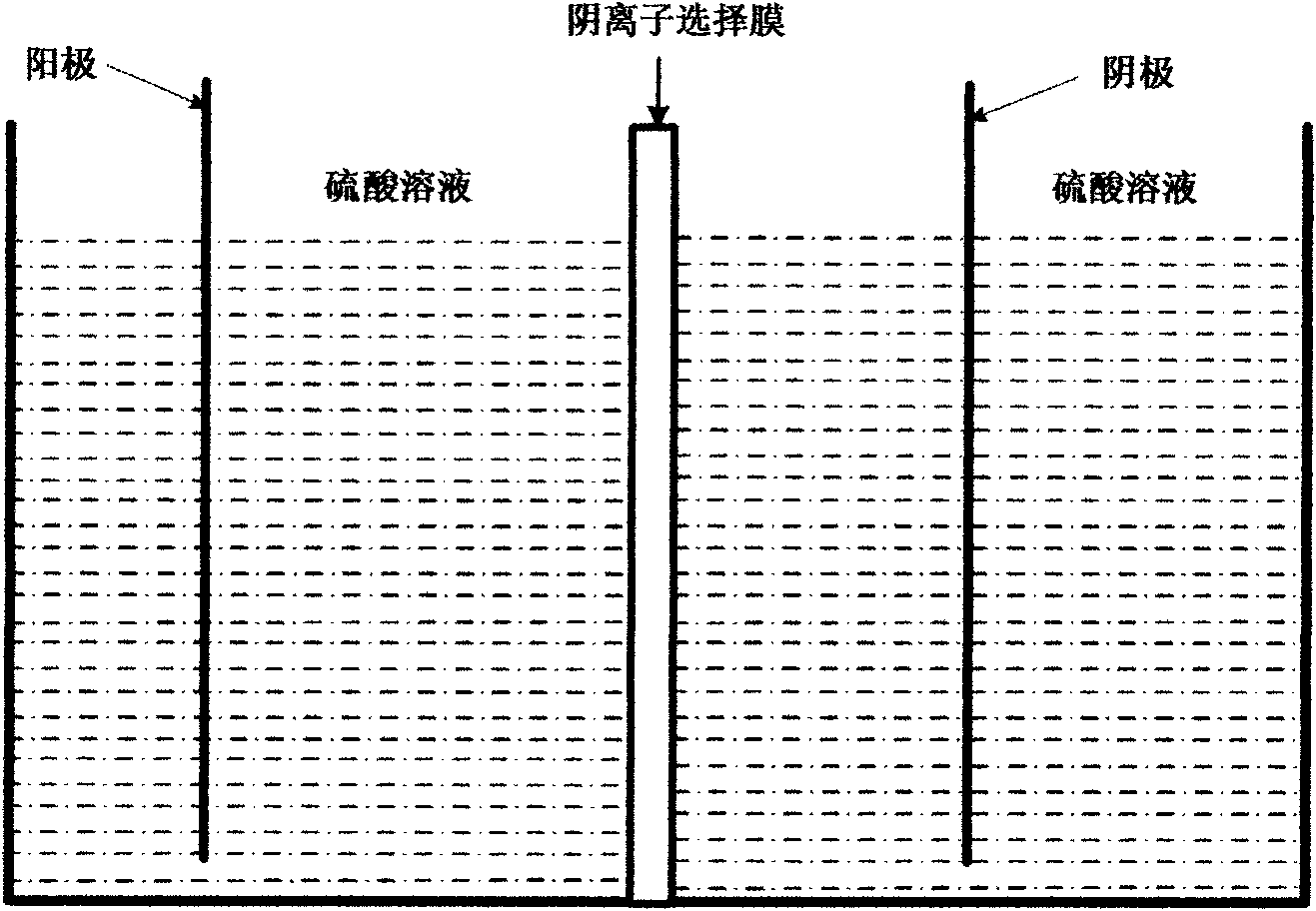

[0016] Add sulfuric acid solution with a concentration of 30% into the electrolytic cell, and add 0.5g / L ammonium thiocyanate additive; pure platinum is the anode, the cathode is the lead plate, and the sulfonic acid-based anion membrane separates the negative and positive areas. The electrolytic voltage is 5V, and the current Density 1500A / m 2 , the reaction temperature is 10°C, ultrasonic electrolysis is performed for 2 hours, and the concentration of the prepared oxidant peroxymonosulfuric acid is 0.459 mol / L.

Embodiment 2

[0018] Add sulfuric acid solution with a concentration of 35% into the electrolytic cell, and add 0.5g / L thiourea additive; pure platinum is the anode, the cathode is the lead plate, and the sulfonic anion membrane separates the negative and positive areas, the electrolytic voltage is 5.5V, and the current density 2500A / m 2 , the reaction temperature is 20 DEG C, ultrasonic electrolysis is carried out for 3 hours, and the concentration of the prepared oxidant peroxymonosulfuric acid is 0.585 mol / L.

Embodiment 3

[0020] Add sulfuric acid solution with a concentration of 25% into the electrolytic cell, and add 0.7g / L ethylenediamine additive; platinum-plated titanium is used as the anode, thermal shock graphite is used as the negative plate, and the sulfonic acid-based anion membrane separates the negative and positive areas, and the electrolytic voltage is 6V , current density 4000A / m 2 , the reaction temperature is 30°C, ultrasonic electrolysis is performed for 4 hours, and the concentration of the prepared oxidant peroxymonosulfuric acid is 0.5625mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com