Production method for controlling content of SO2 contained in starch without adding oxidants

A production method and SO2 technology, which are applied in the field of food processing, can solve the problems that the sulfur dioxide concentration in finished products easily exceeds the standard, the water pollution is large, the soaking time is long, etc., and the food safety requirements are met, the water pollution is small, and the soaking time is short. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

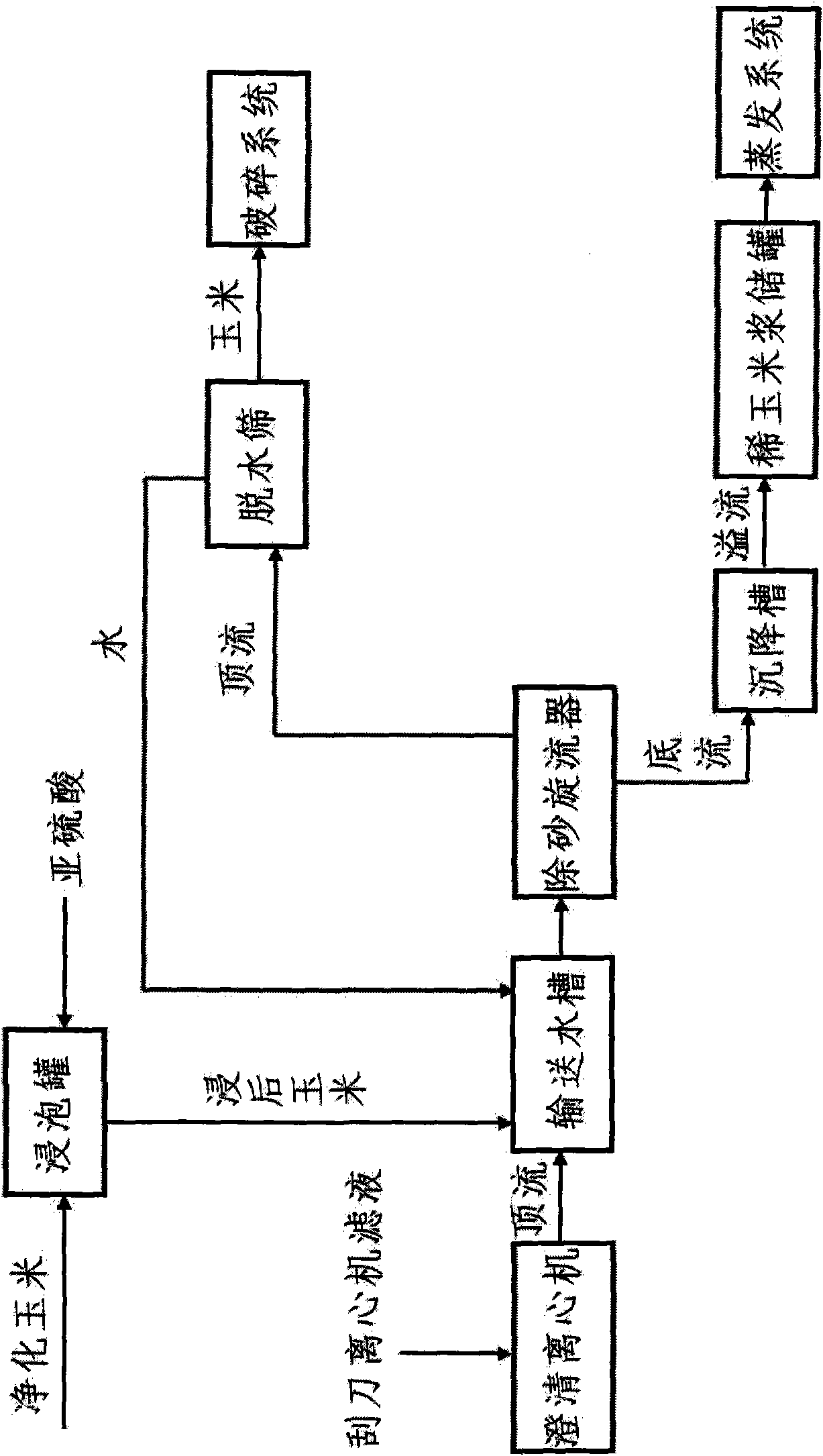

[0017] Such as figure 1 Shown: The present invention purifies corn and sulfurous acid into the steeping tank.

[0018] The first step: the concentration of sulfurous acid used for soaking the corn is 0.05%, and the soaking time is 30 hours; after soaking, the moisture of the corn reaches 45%, and the SO2 content is = 340ppm, and it is sent into the conveying water tank;

[0019] The second step: the filtrate of the scraper centrifuge is separated by a clarification centrifuge, and the supernatant with an SO2 concentration of 30 ppm enters the delivery tank as water for the soaked corn to wash the soaked corn to reduce the SO2 content of the soaked corn.

[0020] Step 3: The washed water in the conveying water tank and the soaked corn enter the desanding cyclone together. Through the action of centrifugal force, the corn and water are discharged from the upper part of the desanding cyclone and enter the dehydration screen for dehydration. The dehydrated corn enters the crushing...

Embodiment 2

[0023] Purified corn and sulfurous acid go into steeping tanks;

[0024] The first step: the sulfurous acid concentration used for soaking the corn is 0.10%, and the soaking time is 20 hours; after soaking, the moisture content of the corn reaches 43%, and the SO2 content is = 330ppm, and it is sent into the conveying water tank;

[0025] The second step: the filtrate of the scraper centrifuge is separated by a clarification centrifuge, and the supernatant with an SO2 concentration of 40 ppm enters the delivery tank as water for the soaked corn to wash the soaked corn to reduce the SO2 content of the soaked corn.

[0026] Step 3: The washed water in the conveying water tank and the soaked corn enter the desanding cyclone together. Through the action of centrifugal force, the corn and water are discharged from the upper part of the desanding cyclone and enter the dehydration screen for dehydration. The dehydrated corn enters the crushing process. system, the water returns to th...

Embodiment 3

[0029] The invention purifies corn and sulfurous acid into the soaking tank.

[0030] The first step: the sulfurous acid concentration used for soaking the corn is 0.08%, and the soaking time is 25 hours; after soaking, the moisture of the corn reaches 43.6%, and the SO2 content is = 338ppm, and it is sent into the conveying water tank;

[0031] The second step: the filtrate of the scraper centrifuge is separated by a clarification centrifuge, and the supernatant with an SO2 concentration of 37 ppm enters the delivery tank as water for the soaked corn to wash the soaked corn to reduce the SO2 content of the soaked corn.

[0032] Step 3: The washed water in the conveying water tank and the soaked corn enter the desanding cyclone together. Through the action of centrifugal force, the corn and water are discharged from the upper part of the desanding cyclone and enter the dehydration screen for dehydration. The dehydrated corn enters the crushing process. system, the water return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com