Reactive emulsifier soap-free styrene surface sizing agent and preparation method thereof

A reactive emulsifier and surface sizing agent technology, which is applied in the addition of water repellents, coatings, paper coatings, etc., can solve the problems of easy film breakage, hair loss, environmental pollution, etc. , The effect of improving the degree of sizing and high surface strength

Inactive Publication Date: 2010-10-27

SHAANXI UNIV OF SCI & TECH

View PDF3 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional surface sizing agents for light paper include starch, oxidized starch, phosphate starch, polyacrylamide modified starch and polyvinyl alcohol, etc., which have poor affinity with fibers during use, and are prone to film formation and breakage. The shortcomings of hair loss, powder loss, poor water resistance, and insufficient surface strength during the printing process limit the scope of application.

At present, styrene-acrylic emulsion is a copolymer prepared by emulsion polymerization of styrene and acrylate monomers. Small-molecule emulsifiers are often used in the preparation process, which not only affects the water resistance and film-forming properties of light-duty paper, but also causes environmental pollution.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

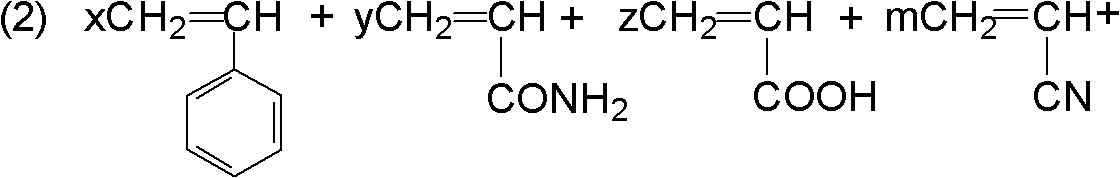

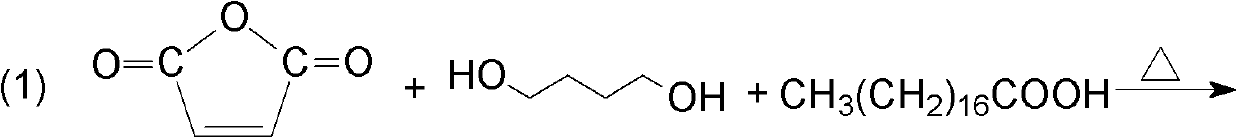

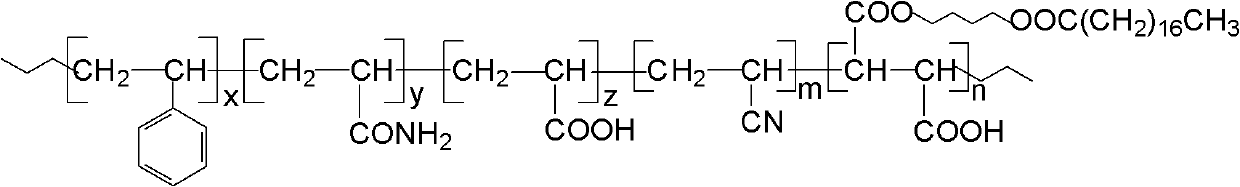

The invention discloses a reactive emulsifier soap-free styrene surface sizing agent and a preparation method thereof; the molecular structure of the reactive emulsifier soap-free styrene surface sizing agent is shown as the accompanying drawing. The preparation method of the reactive emulsifier soap-free styrene surface sizing agent comprises the following steps that: first, polyethylene glycol, stearic acid and maleic anhydride react to obtain maleic acid polyethylene glycol single-stearic acid ester; then ammonium persulfate serves as an initiator, and the maleic acid polyethylene glycol single-stearic acid ester, styrene, acrylamide, acrylic acid and acrylonitrile are prepared into the reactive emulsifier soap-free styrene surface sizing agent through copolymerization reaction; and the obtained reactive emulsifier soap-free styrene surface sizing agent eliminates the disadvantages and the pollution of small molecule emulsifier, and is characterized by excellent integration with fibers, reduced hair and powder drop, higher seizing degree, high surface strength, capability of adapting to high-speed printing and the like.

Description

technical field The invention relates to the field of preparation of light paper surface sizing agents, in particular to a reactive emulsifier soap-free styrene-acrylic surface sizing agent and a preparation method thereof. Background technique Lightweight paper is a kind of light offset paper. It has a unique production process, does not contain fluorescent whitening agents, and has light fiber specific gravity, bulky texture, smooth surface, and soft color. It is more suitable for printing color books and periodicals, and is popular among people favor. Due to the lighter texture of light paper, the weight of books and periodicals printed on it can be reduced by about 20%-30% compared with those printed on ordinary paper, which is not only convenient for readers to read, but also plays a better role in reducing logistics costs. Therefore, light paper has replaced part of the application market of offset paper and coated paper in printing books and magazines, and the produc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F283/06C08F212/08C08F220/56C08F220/06C08F220/44C08F2/24D21H19/12D21H21/16

Inventor 张国运杨秀芳徐永建付旭东彭莉杨军胜

Owner SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com