Technology for extracting arachidonic acid oil by aqueous enzymatic extraction

A technology of arachidonic acid and water enzymatic method, applied in the direction of producing fat, fat oil/fat production, etc., can solve the problems of difficult to realize industrialization, large amount of cooling water, difficult to extract in batches, etc., and achieves simple equipment, reduced operating costs, Applicable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

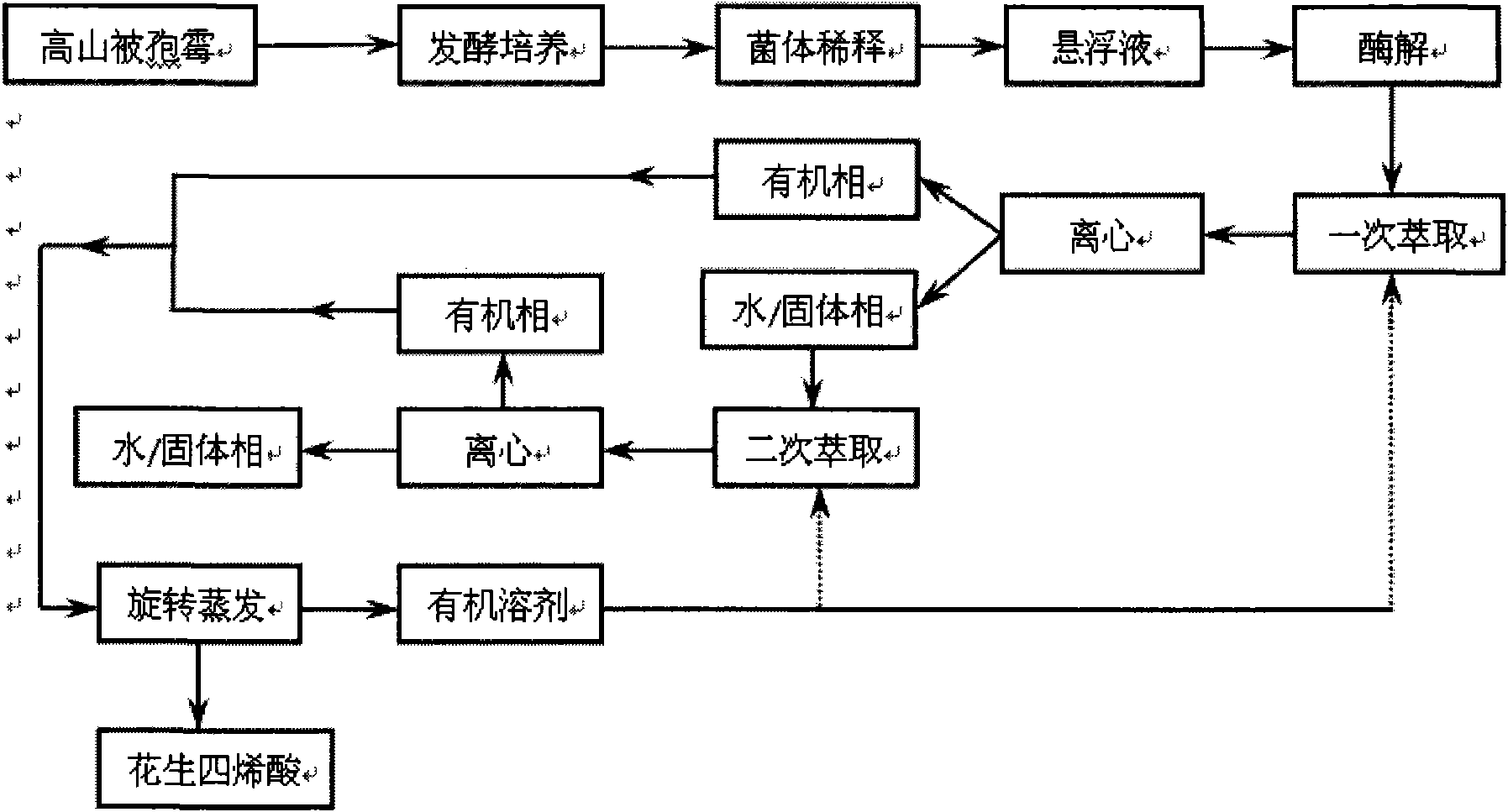

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: strain fermentation culture

[0037] The medium formula is as follows:

[0038] Seed medium: 100g / L glucose, 11g / L yeast powder, 8g / L corn steep liquor, 3.8g / L KH 2 PO 4 , the initial pH is 5.0-6.0.

[0039] Fermentation medium: 100g / L glucose, 11g / L yeast powder, 3.8g / L KH 2 PO 4 , 3.4g / L NaNO 3 , 0.5g / LMgSO 4 .7H 2 O. The initial pH is 5.5-6.5.

[0040] 1) Activation of strains

[0041] Before preparing the seeds, the PDA slant is used to activate the strains, and the activated strains are transferred to the PDA solid medium for 3-5 days to accumulate a large number of spores for future use.

[0042] 2) The seeds are enlarged once

[0043]After the spores of Mortierella alpina grown on the PDA solid medium were eluted with sterile water, they were inserted into a grooved shake flask filled with seed medium through aseptic operation. The liquid volume of the shake bottle is 50ml / 250ml. Seed culture conditions: the rotation speed of the shaker...

Embodiment 2

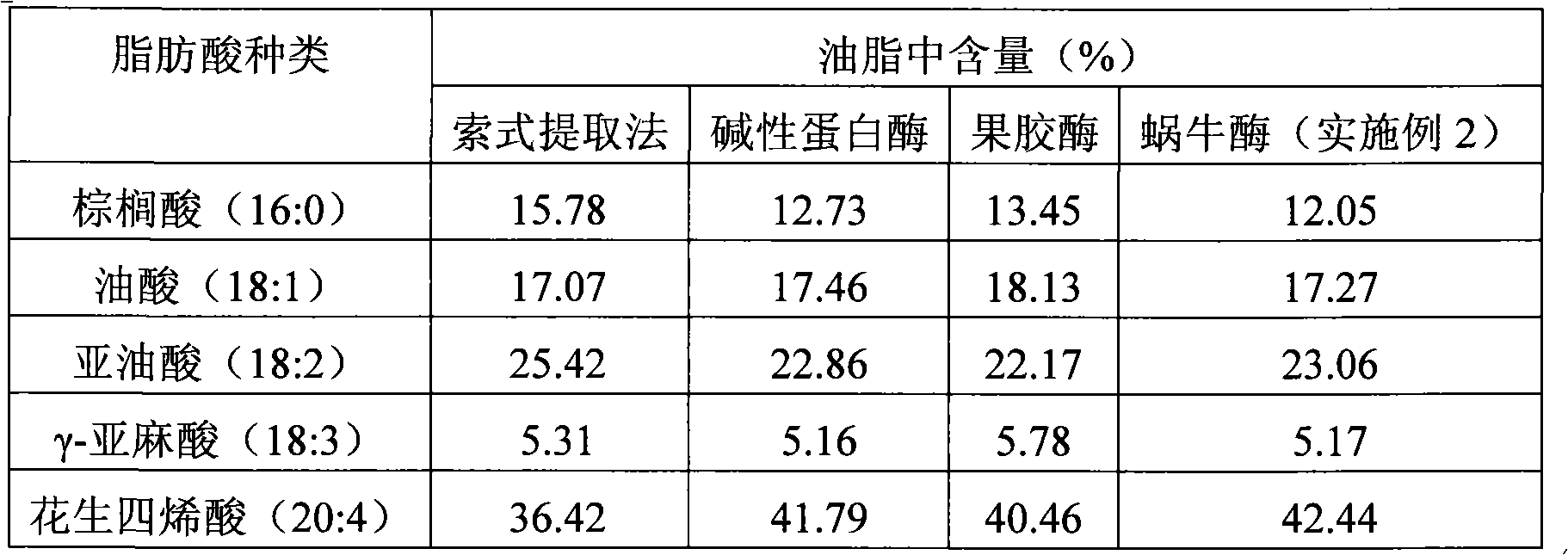

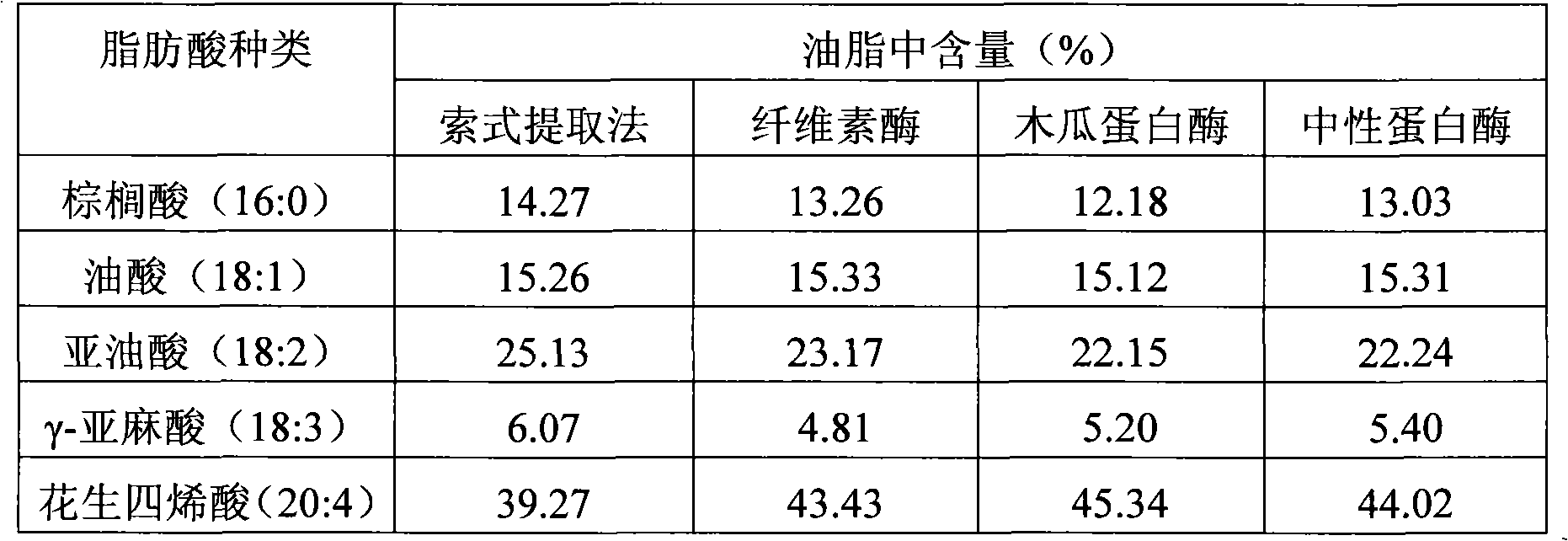

[0049] According to Example 1, ferment and cultivate the thallus, add distilled water to the fermentation liquid and dilute it by 2 volume multiples to make a thallus suspension, adjust the pH value to 6.0, divide it into 50mL test tubes according to 30mL equal amounts, add 20mg of helicase, and heat at 40°C Shake at constant temperature for 8 hours; add 4 mL of ethanol and 10 mL of n-hexane for the first extraction, centrifuge at 5000 rpm for 5 min to take the organic phase, add 10 mL of n-hexane to the remaining aqueous phase and solid phase for secondary extraction, and centrifuge at 5000 rpm for 5 min to get the organic phase , the combined organic phase was rotary evaporated to obtain 0.4854g of organic solvent and arachidonic acid oil, and the control group Soxhlet extraction method obtained 0.4994g of oil, and the oil yield was 97.2%.

Embodiment 3

[0051] According to Example 1, ferment and cultivate the thallus, add distilled water to the fermentation broth to dilute 2 volume multiples to make a thallus suspension, adjust the pH value to 6.0, divide into 50mL test tubes according to 30mL equal amounts, add 20mg of helicase, and heat at 37°C Shake at constant temperature for 8 hours; add 4.5mL of ethanol and 10mL of n-hexane for the first extraction, centrifuge at 5000rpm for 5min to take the organic phase, add 10mL of n-hexane to the remaining aqueous phase and solid phase for secondary extraction, centrifuge at 5000rpm for 5min to take the organic phase Phase, combined organic phase rotary evaporation to obtain organic solvent and arachidonic acid oil 0.4752g, control group Soxhlet extraction method to obtain oil 0.4994g, oil yield was 95.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com