Optical cavity micro-accelerometer based on integrated input/output terminal

A technology of optical resonant cavity and micro-accelerometer, which is applied in the direction of acceleration measurement using inertial force and optical waveguide coupling, etc., which can solve the problems that are not conducive to phase accumulation of planar ring microcavity, unfavorable evanescent wave coupling to continue transmission, and unfavorable high-efficiency coupling etc. to achieve the effects of simple structure, increased phase accumulation, and improved coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0028] [0027 The present invention adopts silicon SOI material as a whole, the top layer structure adopted is silicon SOI material, the thickness is 220nm-300nm, and the oxide layer is silicon dioxide SiO 2 , the thickness is 1 μm-1.5 μm, the substrate layer is silicon, and the thickness is 550 μm-600 μm.

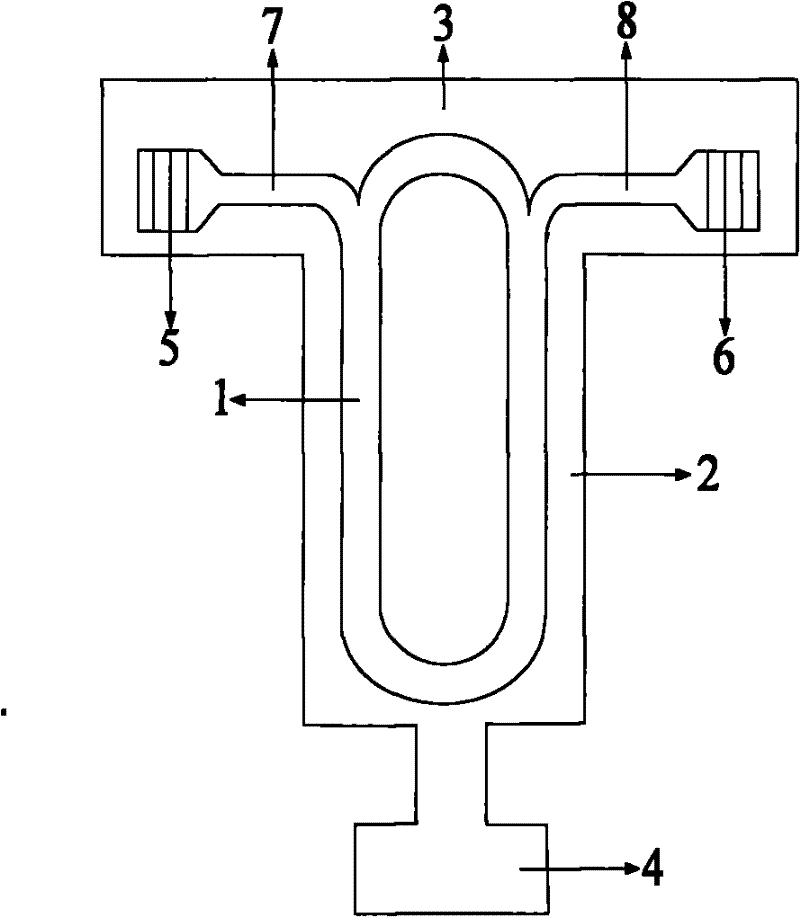

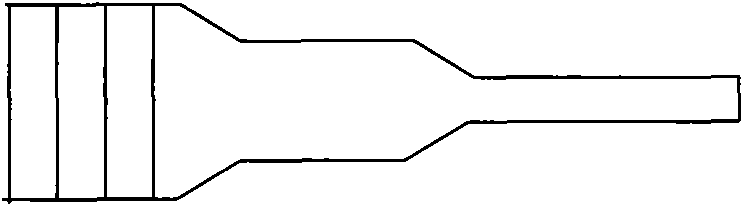

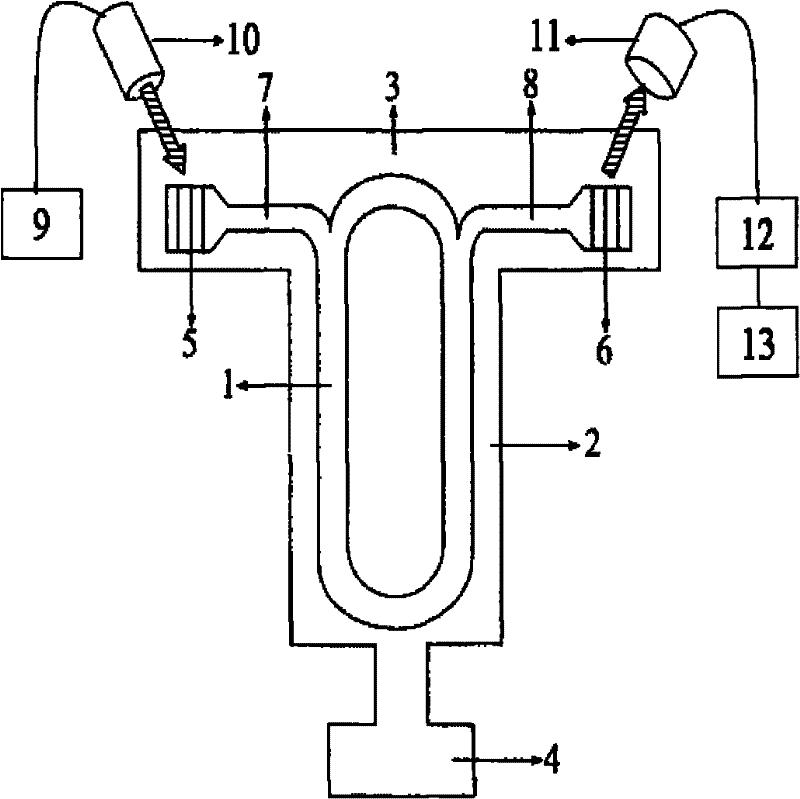

[0029] (1) Optical resonant cavity: The optical resonant cavity with integrated input and output ends is formed by photolithography on the top layer of SOI silicon and the oxide layer of silicon dioxide. The silicon dioxide is also etched to ensure the single mode of light in the silicon layer. transmission. The width of the input optical waveguide end and the output optical waveguide end of the optical resonant cavity is 500nm-550nm, and the width of the input optical waveguide and the output optical waveguide parallel to both sides of the optical resonant cavity is 550nm-600nm, that is, the input optical waveguide end and the output optical waveguide end. The width of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com