Production method of food capable of reducing after-dinner blood sugar of diabetes patients

A postprandial blood sugar, production method technology, applied in food preparation, food science, application and other directions, can solve the problems of elevated blood sugar, no diabetes found, etc., to reduce postprandial blood sugar, reduce the effect of decomposition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Take the following weights of ingredients:

[0041] Rice 40kg, buckwheat 35kg, oat 20kg, meat protein 6kg, egg protein 8kg, konjac flour 9kg, fructooligosaccharide 5kg, tea seed oil 6kg, peanut oil 5kg, medium chain oil 2kg soybean protein 7.5kg.

[0042] Process starch-rich raw materials (rice, buckwheat and oats) into granules or small pieces or powders and soak them well in water;

[0043] B. Add 350kg of water to the product of step A, then put it into a retort-proof container for heating and boiling until it is completely gelatinized; after keeping it warm for 1 hour, cool it naturally or freeze it to 2°C, dry it and pulverize it to get aging powder 85kg;

[0044] C. Emulsify tea seed oil and other oils in raw materials, 51kg of aging powder and nutrients to be strengthened, then spray dry, mix the product with the remaining 34kg of aging powder, dry and sterilize, and then pack to obtain the target product Nutrition powder.

Embodiment 2

[0046] Take the following weights of ingredients:

[0047] Rice 20kg, buckwheat 50kg, oat 8kg, meat protein 8kg, egg protein 3kg, konjac flour 11kg, tea seed oil 4kg, peanut oil 2kg, medium chain oil 1kg, sunflower oil 2.5kg, soybean protein 5.5kg.

[0048] A. Process starch-rich raw materials (rice, buckwheat and oats) into granules or small lumps or powder, and fully soak in water;

[0049] B. Add 350 kg of water to the product of step A, then put it into a retort-proof container for heating and boiling, until it is completely gelatinized; after 2 hours of heat preservation, naturally cool or freeze to 2°C, dry and pulverize to obtain aging powder 70kg;

[0050] C. Emulsify the oil (all), 35kg of aging powder and nutrients to be strengthened in the raw material, spray dry, mix the product with the remaining 35kg of aging powder, dry and sterilize, and then pack to obtain the target product nutritional powder .

Embodiment 3

[0052] Take the following weights of ingredients:

[0053] Rice 50kg, buckwheat 20kg, oat 30kg, meat protein 2kg, egg protein 11kg, konjac flour 6kg, peanut oil 5kg, coconut oil 2kg, corn oil 6kg, soybean protein 9kg.

[0054]Process starch-rich raw materials (rice, buckwheat and oats) into granules or small pieces or powders and soak them well in water;

[0055] B. Add 350kg of water to the product of step A, then put it into a retort-proof container for heating and boiling until it is completely gelatinized; after keeping it warm for 1 hour, cool it naturally or freeze it to 2°C, dry it and pulverize it to get aging powder 90kg;

[0056] C. emulsify the vegetable oil (all), 40kg of aging powder and the nutrients that need to be strengthened and spray dry, then mix the product with the remaining 50kg of aging powder, dry and sterilize, and then pack to obtain the target product nutrition powder.

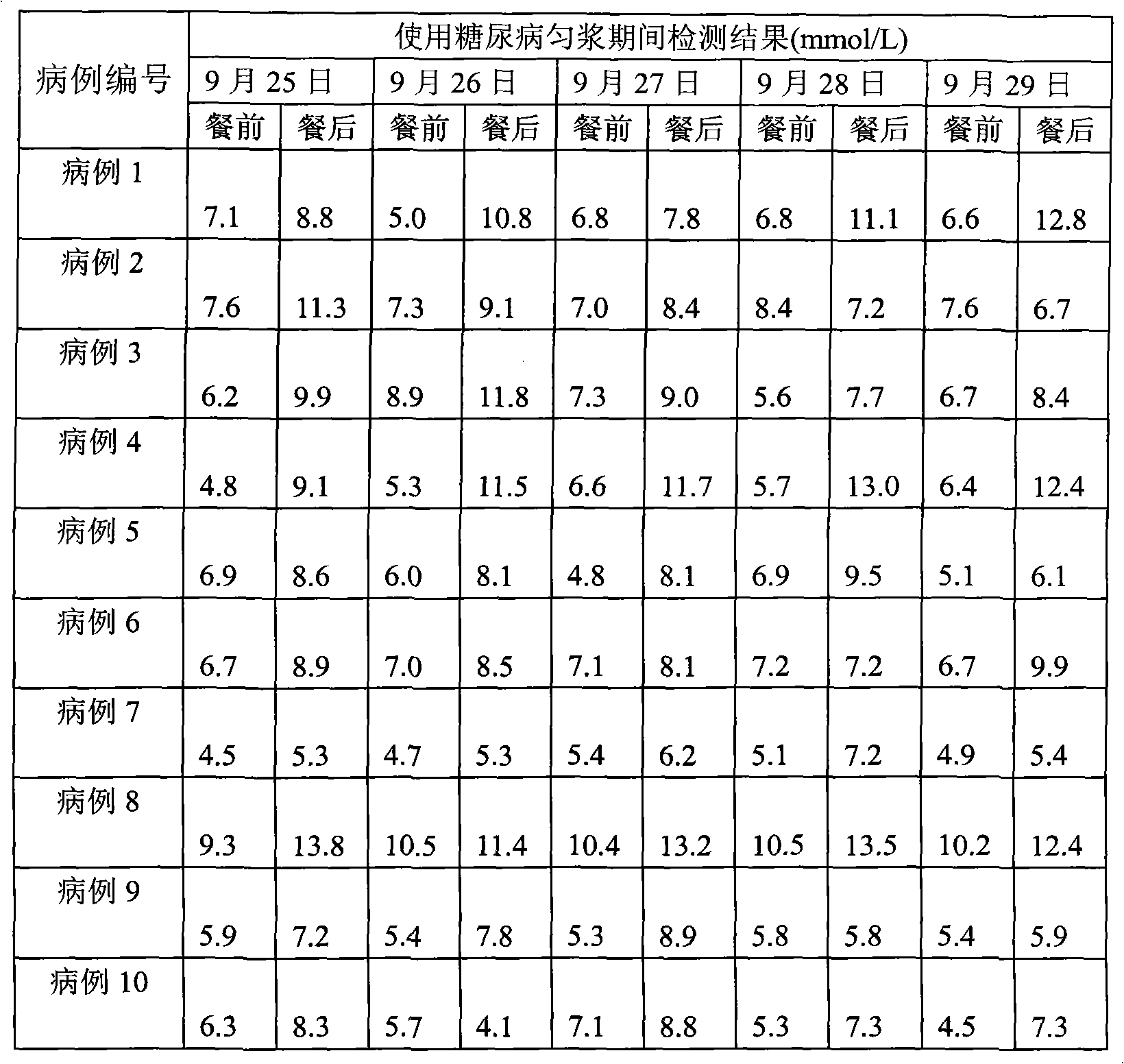

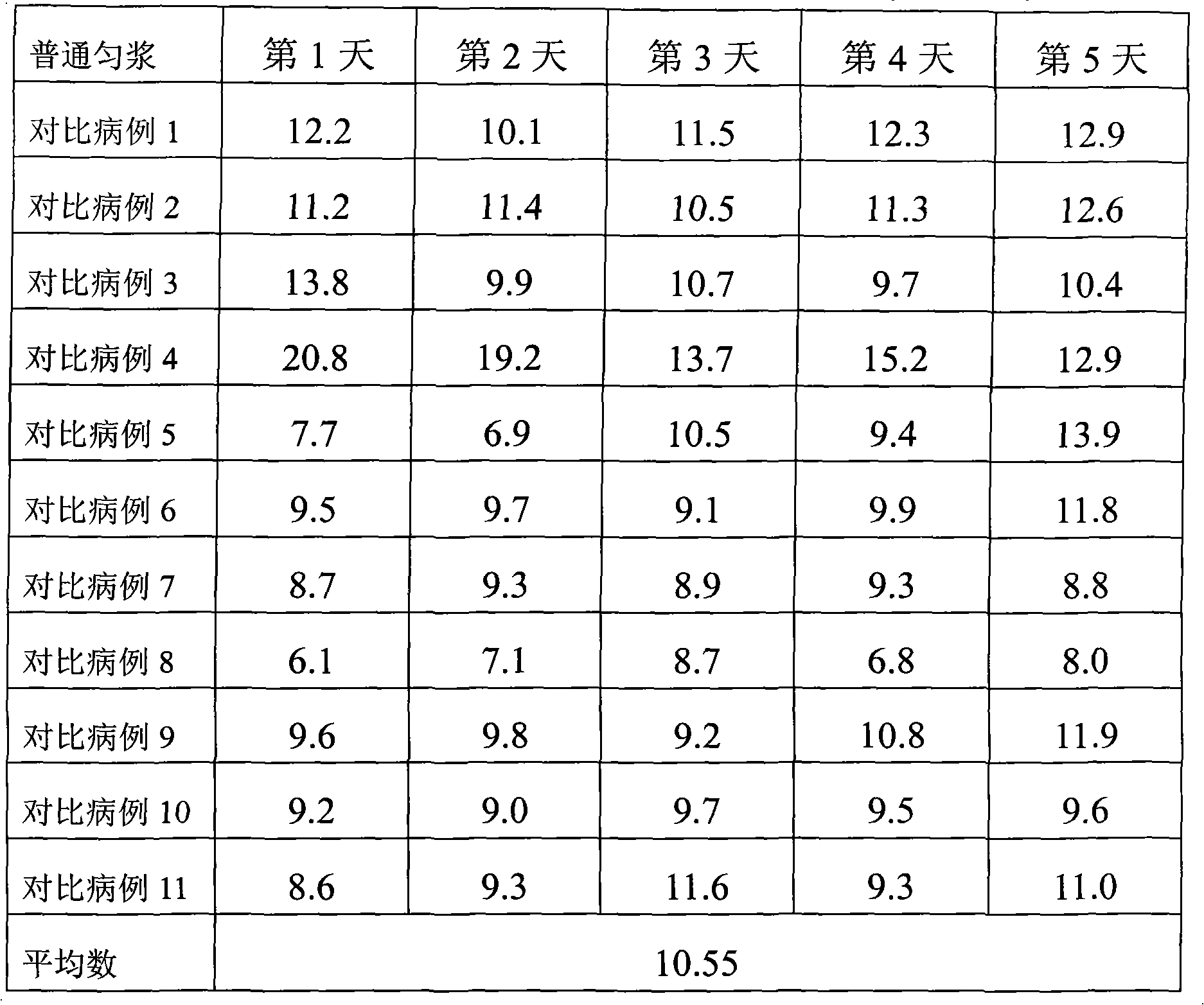

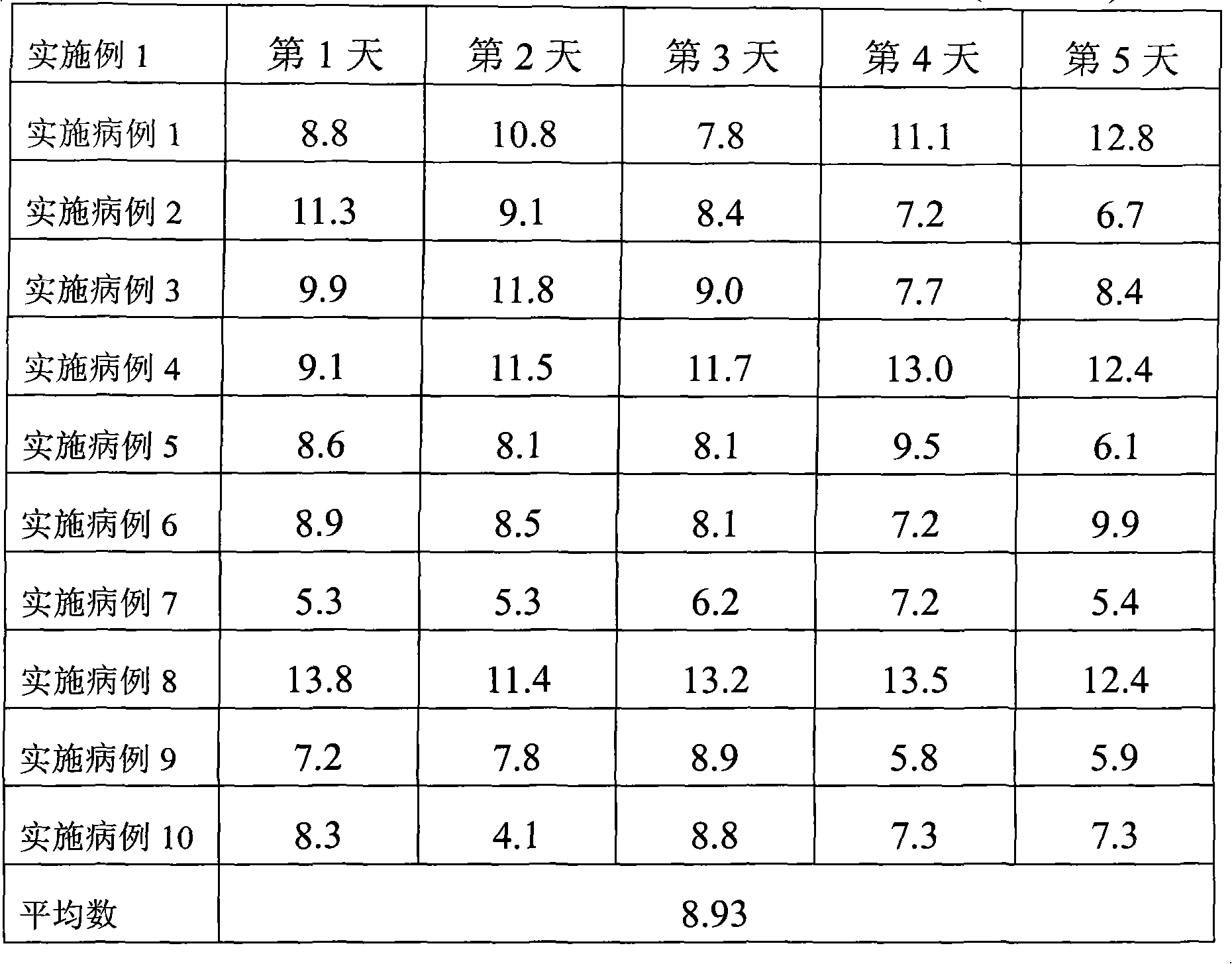

[0057] The product of embodiment 1 is given to diabetics, and each case perso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com