A kind of yttrium sol bonded yttrium oxide mold shell and preparation method thereof

A technology of yttrium oxide and yttrium sol, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of casting surface or internal pollution, damage to casting quality, etc., and achieve thermal shock resistance, not easy to deform, process Effects with controllable parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

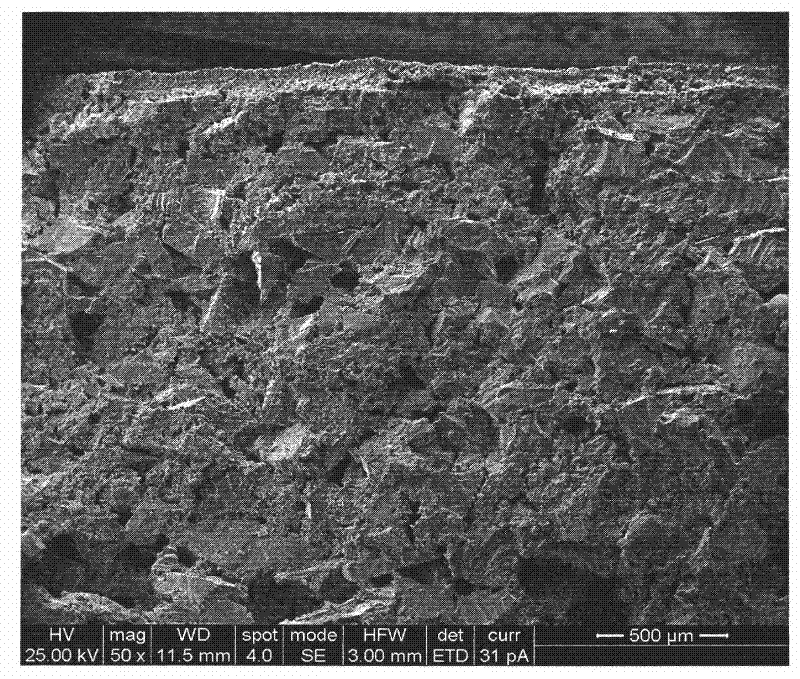

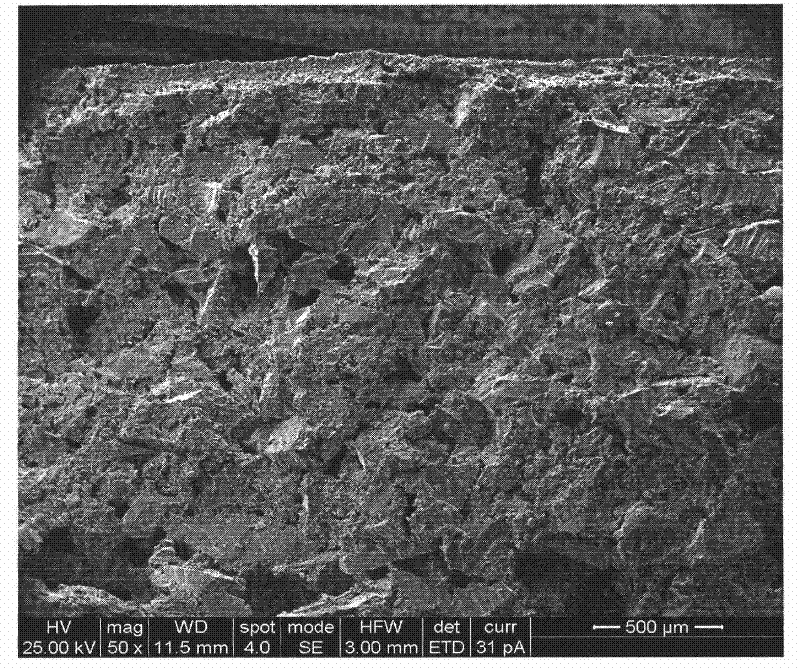

Image

Examples

Embodiment 1

[0063] Yttrium sol-bonded yttrium oxide formwork for directionally solidified Ti-47Al-2Cr-2Nb alloy rods

[0064] The first step: prepare the formwork slurry

[0065] The mold shell slurry is composed of yttrium sol, yttrium oxide powder, defoamer and surfactant, wherein the content of 325 mesh yttrium oxide powder accounts for 79% of the total weight of the slurry, and the content of yttrium sol accounts for 20% of the total weight of the slurry. N-octanol accounts for 0.5% of the total weight of the slurry, and JFC content accounts for 0.5% of the total slurry.

[0066] Step Two: Prepare the Formwork

[0067] (A) immerse the wax pattern of casting shape into the slurry prepared in the first step for 5 seconds and then take it out, sprinkle with 60 mesh yttrium oxide sand to form the first preform;

[0068] (B) placing the first preform in a constant temperature and humidity environment with a temperature of 20° C. and a relative humidity of 60% for 30 hours to obtain a sec...

Embodiment 2

[0087] Yttrium Sol Bonded Yttrium Oxide Formwork for Casting Nb-16Si-22Ti-17Cr-2Hf-2Al Alloy

[0088] The first step: prepare the formwork slurry

[0089] The formwork slurry is composed of yttrium sol, yttrium oxide powder, defoamer and surfactant, wherein the content of 325 mesh yttrium oxide powder accounts for 60% of the total weight of the formwork slurry, and the content of yttrium sol accounts for 60% of the total weight of the formwork slurry. 39.9%, n-amyl alcohol accounts for 0.05% of the total weight of the formwork slurry, and the content of OP-10 accounts for 0.05% of the total formwork slurry.

[0090] Step Two: Prepare the Formwork

[0091] (A) immerse the wax pattern of casting shape into the slurry prepared in the first step for 2 seconds and then take it out, sprinkle with 80 mesh yttrium oxide sand to form the first preform;

[0092] (B) placing the first preform in a constant temperature and humidity environment with a temperature of 35° C. and a relative...

Embodiment 3

[0110] Yttrium Sol Bonded Yttrium Oxide Formwork for Directional Solidification of Nb-16Si-22Ti-2Al-6Hf-2Cr Alloy

[0111] The first step: prepare the formwork slurry

[0112] The formwork slurry is composed of yttrium sol, yttrium oxide powder, defoamer and surfactant, wherein the content of 325 mesh yttrium oxide powder accounts for 65% of the total weight of the formwork slurry, and the content of yttrium sol accounts for the total weight of the formwork slurry. 34%, isopropanol accounts for 0.5% of the total weight of the formwork slurry, and the OP-7 content accounts for 0.5% of the total formwork slurry.

[0113] Step Two: Prepare the Formwork

[0114] (A) immerse the wax pattern of casting shape into the slurry prepared in the first step for 8 seconds and then take it out, sprinkle with 100 mesh yttrium oxide sand to form the first preform;

[0115] (B) placing the first preform in a constant temperature and humidity environment with a temperature of 25° C. and a rela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com