Method for preparing high-purity brookite titanium dioxide with controlled appearance

A technology of brookite type and titanium dioxide, which is applied in the field of material chemistry and photocatalysis, can solve the problems of single shape, complicated steps, expensive raw materials, etc., and achieve the effect of simple steps, cheap raw materials and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Under stirring state, add anhydrous sodium acetate to 0.4mol / L titanium sulfate solution, make the concentration of sodium acetate be 1.0mol / L, then adjust the suspension system with 1.0mol / L sodium hydroxide solution The pH value is 11; the suspension precursor obtained above is subjected to a hydrothermal reaction at 240°C for 6 days in a hydrothermal kettle, then taken out, washed, and dried to obtain a petal-shaped brookite-type titanium dioxide product with a purity of more than 99.0%.

Embodiment 2

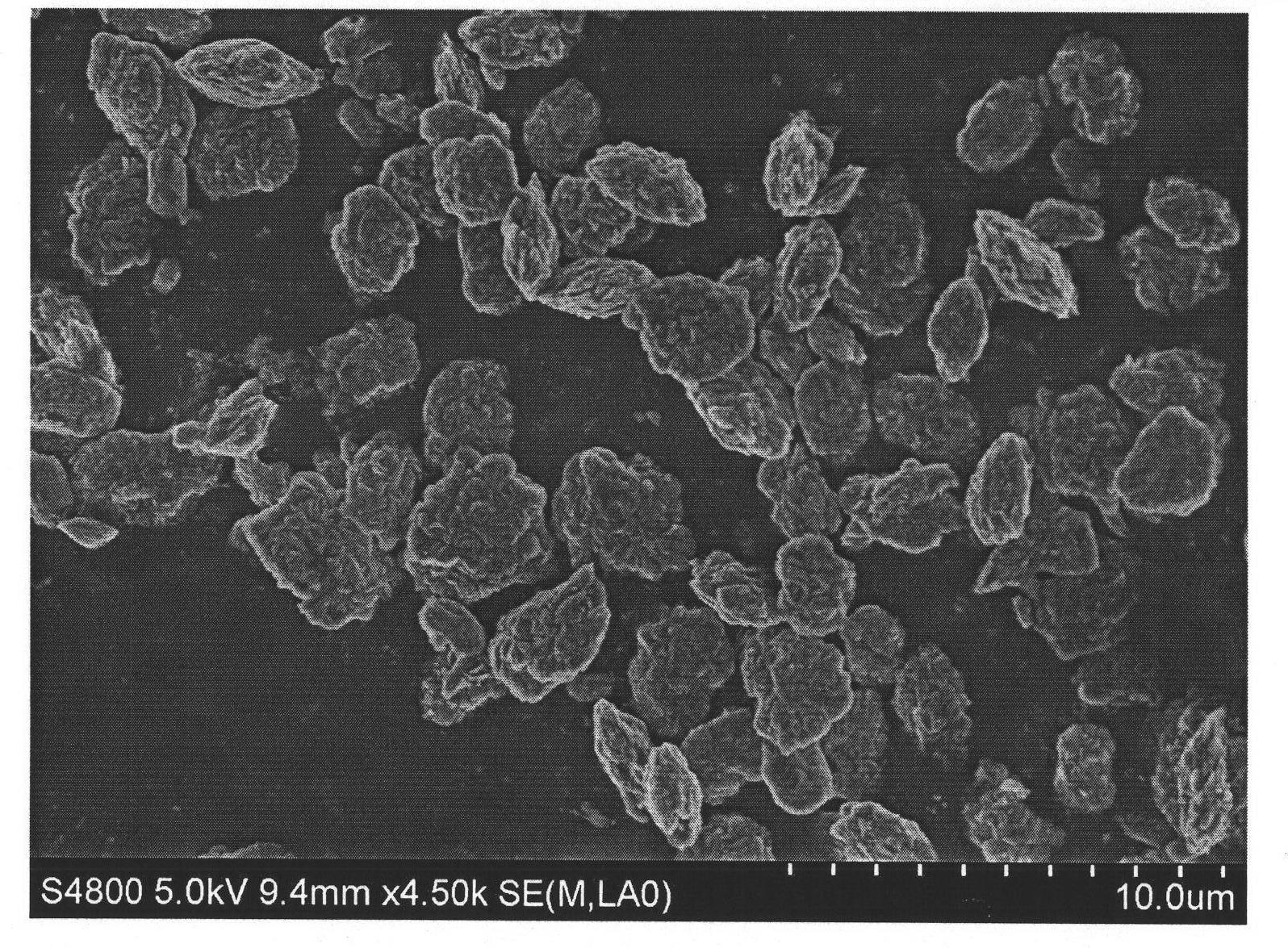

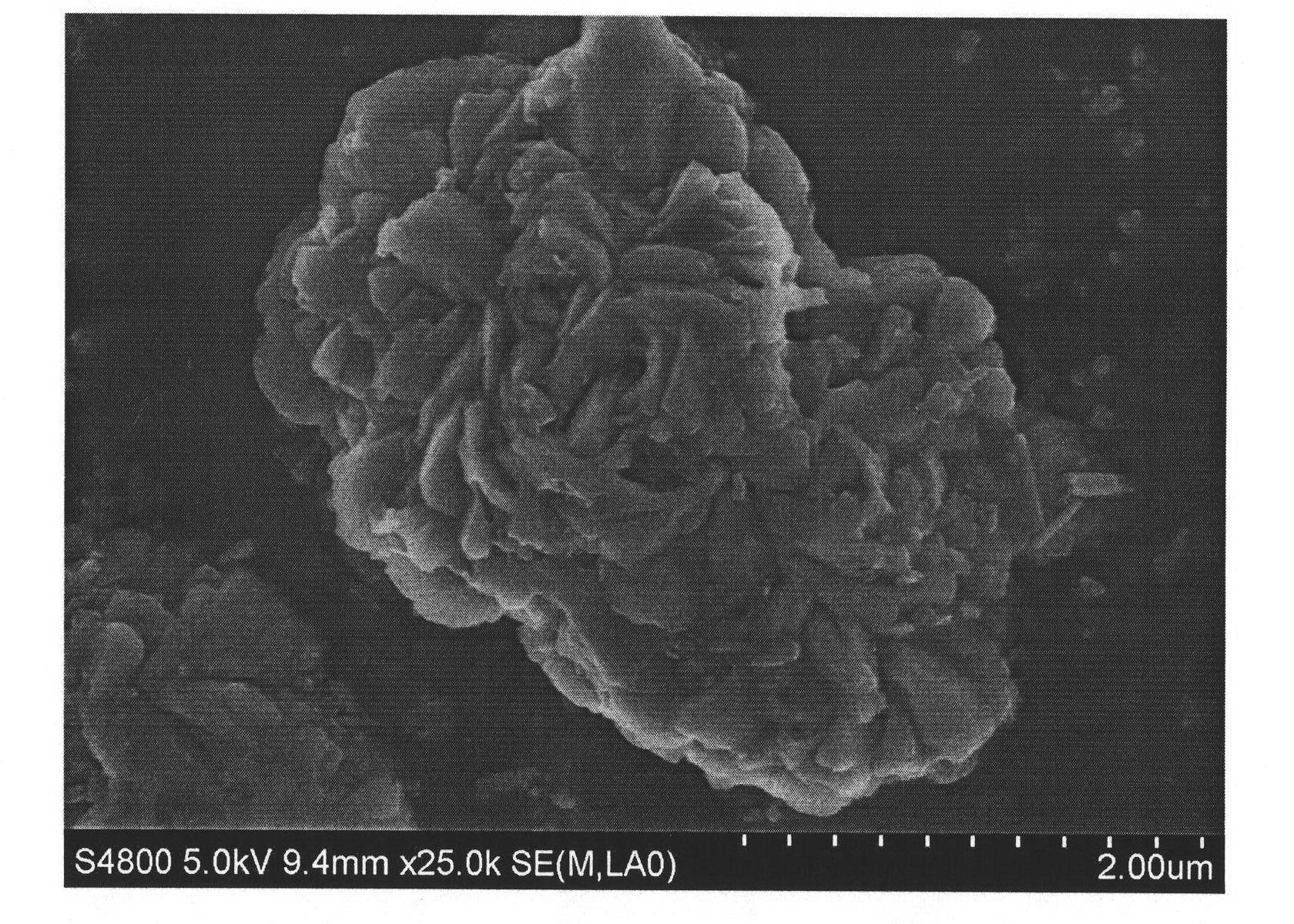

[0021] Under stirring state, add anhydrous sodium acetate to 0.1mol / L titanium sulfate solution, make the concentration of sodium acetate be 1.0mol / L, then adjust the suspension system with 1.0mol / L sodium hydroxide solution The pH value is 9; the suspension precursor obtained above is subjected to a hydrothermal reaction at 300° C. for 4 days in a hydrothermal kettle, then taken out, washed, and dried to obtain a petal-shaped brookite-type titanium dioxide product with a purity of more than 99.0%. as attached figure 1 , 2 , 5a shown.

Embodiment 3

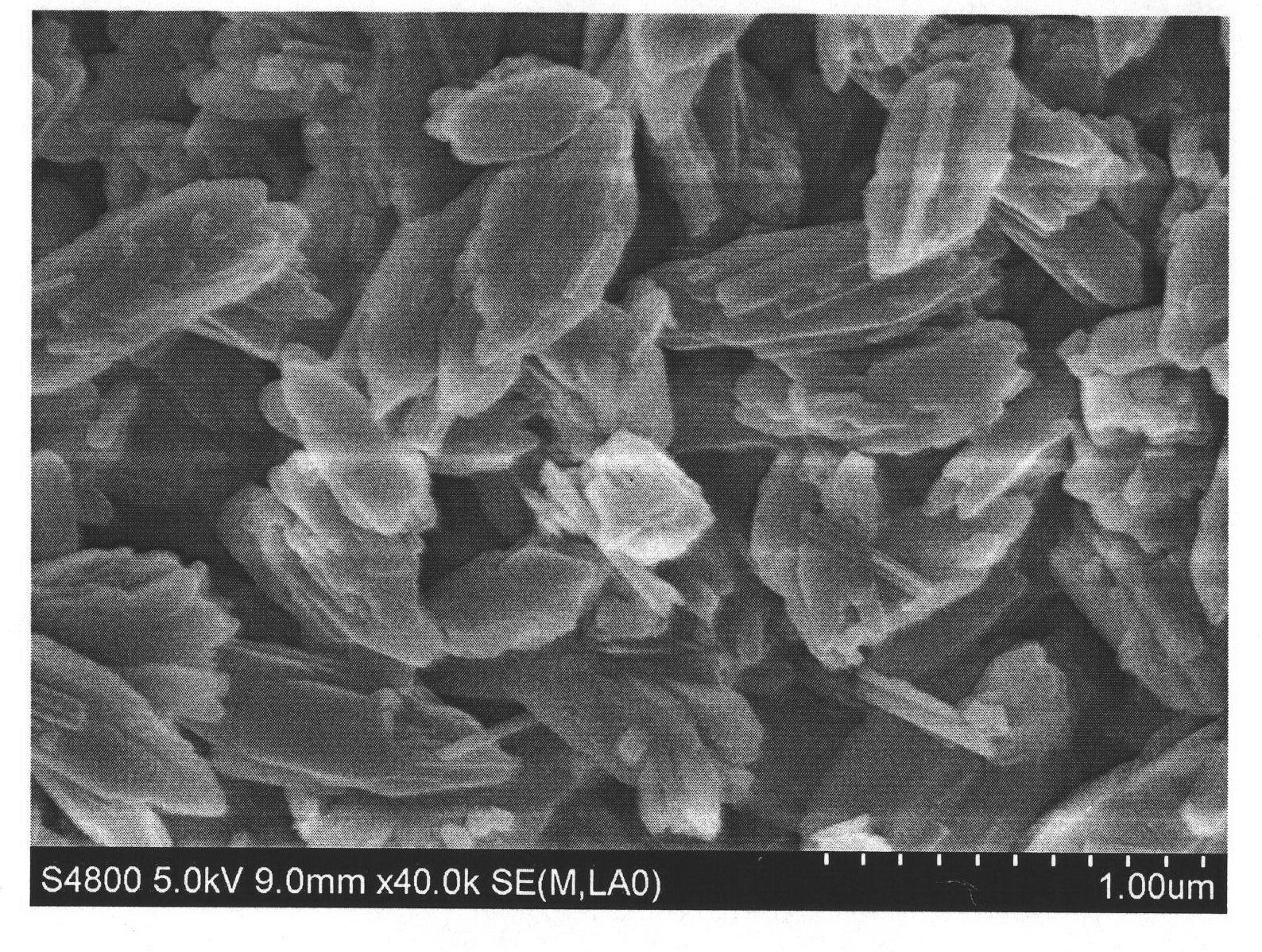

[0023] Under stirring state, add anhydrous sodium acetate to the titanium sulfate solution of 0.05mol / L, make the concentration of sodium acetate be 1.0mol / L, then adjust the suspension system with 1.0mol / L sodium hydroxide solution The pH value is 12; the suspension precursor obtained above is subjected to a hydrothermal reaction at 180° C. for 6 days in a hydrothermal kettle, then taken out, washed, and dried to obtain a brookite-type titanium dioxide product in the shape of a shuttle with a purity of more than 99.8%. as attached image 3 , 5 as shown in b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com