Hazardous waste high-temperature melting microcrystal purification device and tail gas purification method

A high-temperature melting and purification device technology, which is applied in the direction of combustion methods, incinerators, lighting and heating equipment, etc., can solve problems such as inability to achieve reduction, large floor space, and excessive heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

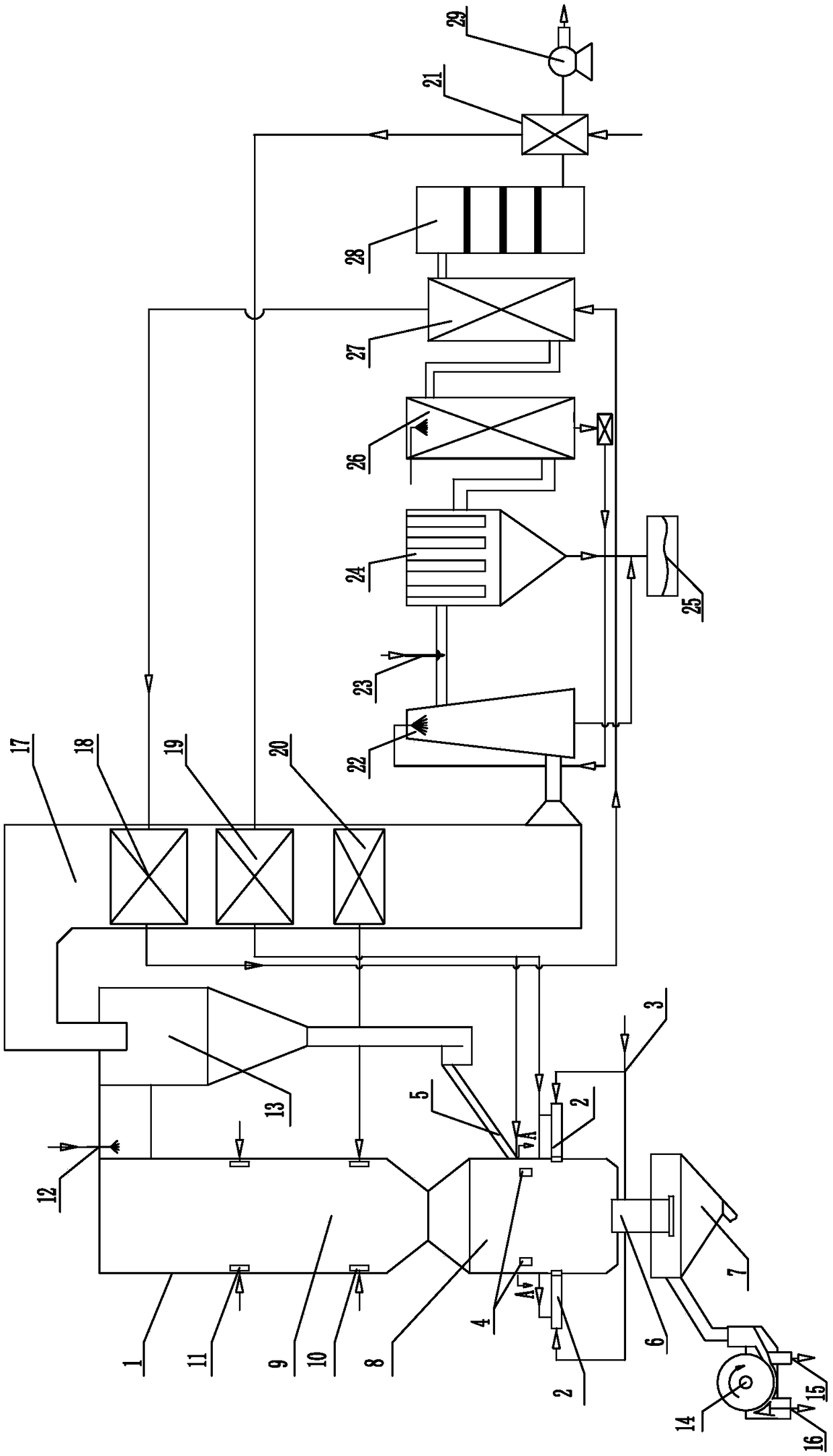

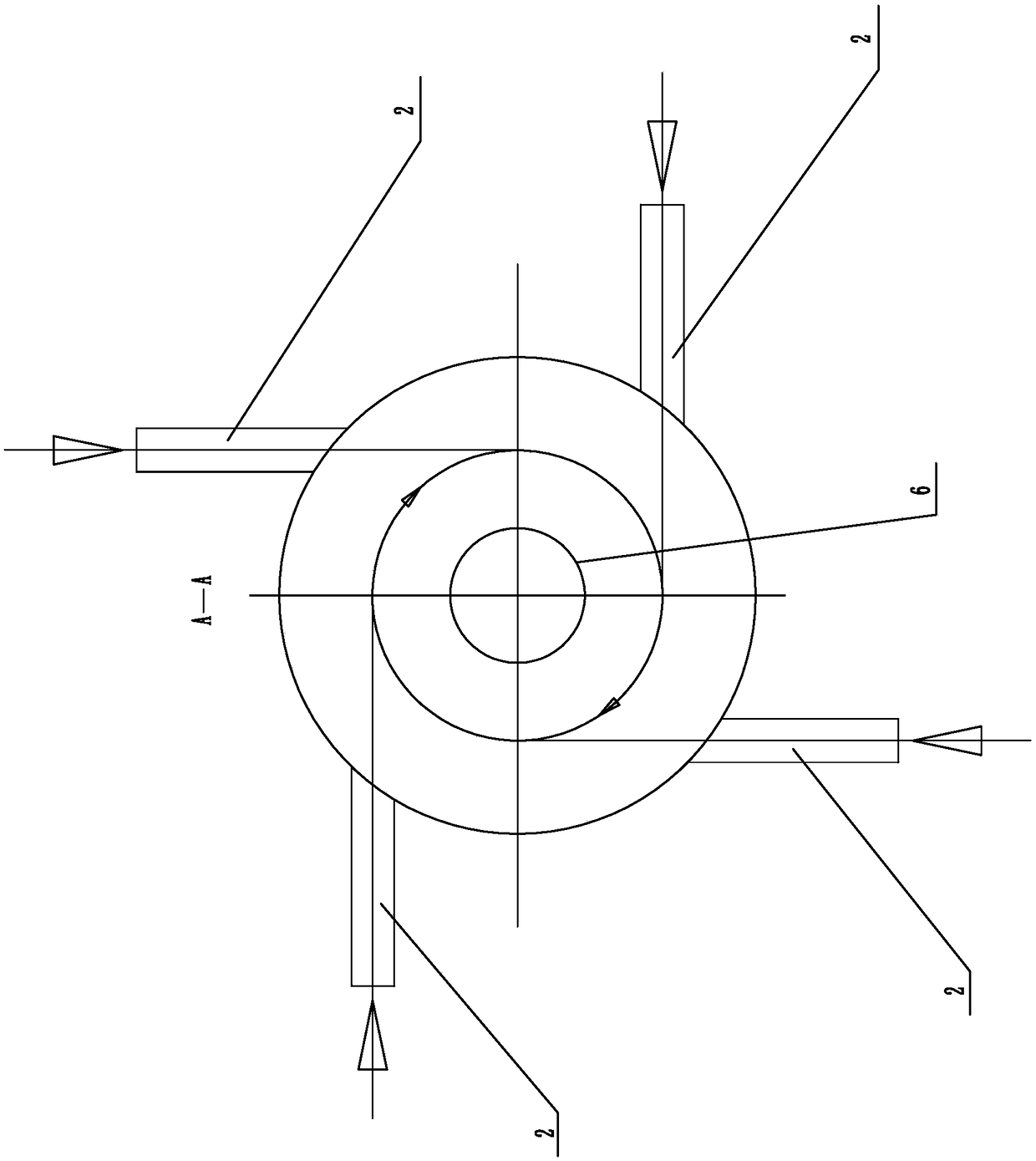

[0024] Specific implementation mode one: as figure 1 , figure 2As shown, this embodiment discloses a hazardous waste high-temperature melting microcrystal purification device, which consists of a melting furnace body 1, a gas pipeline 3, a material return port 5, a slag discharge port 6, a molten slag water quenching pool 7, a secondary Air nozzle 10, recirculation flue gas nozzle 11, SNCR urea nozzle 12, cyclone separator 13, magnetic separator 14, microcrystalline raw material slag outlet 15, heavy metal outlet 16, tail flue 17, thermal oil economizer 18, High temperature air preheater 19, medium temperature air preheater 20, low temperature air preheater 21, cooling tower 22, slaked lime and activated carbon nozzle 23, bag filter 24, secondary ash bin 25, wet flue gas purification device 26, Flue gas heater 27, SCR denitrification device 28, induced draft fan 29, four burners 2 and four feeding ports 4;

[0025] The melting furnace body 1 is composed of a melting chamber...

specific Embodiment approach 2

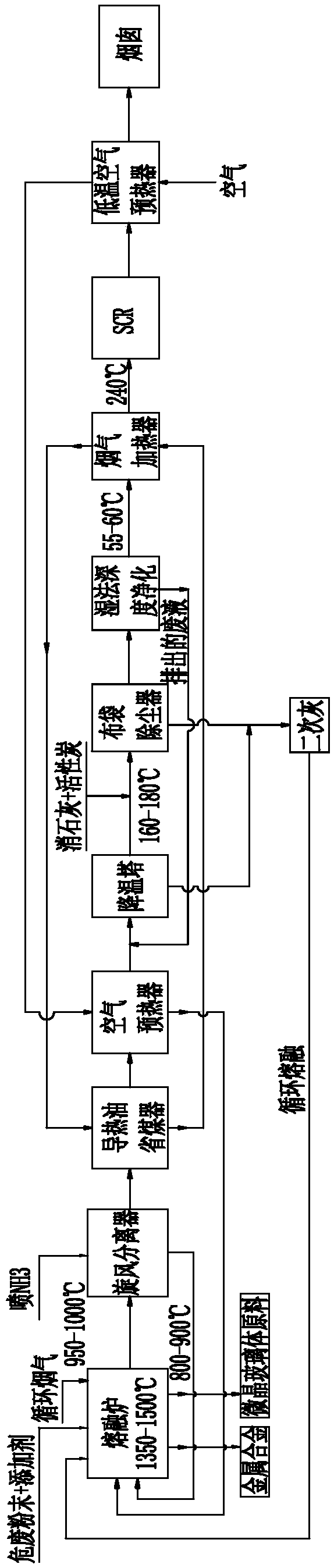

[0026] Specific implementation mode two: as Figure 1-Figure 3 As shown, this embodiment discloses a method of using the device described in Embodiment 1 to realize the purification of hazardous waste high-temperature molten microcrystals and tail gas purification. The steps of the method are as follows:

[0027] Step 1: Mix the powder of hazardous waste to less than 0.1mm into nucleating agent and flux. The weight of nucleating agent used accounts for 3-5% of the weight of hazardous waste, and the proportion of flux used is less than 10% of the weight of hazardous waste. Mix The final hazardous waste material is sent into the melting chamber 8 through the feed port 4;

[0028] Step 2: The hot primary air and gas preheated by the high-temperature air preheater 19 are sent tangentially into the melting chamber 8 through the burner 2 to form vortex combustion, and the hazardous waste powder fed in is rapidly heated to a molten state, and the melting chamber The temperature insi...

specific Embodiment approach 3

[0033] Specific embodiment three: This embodiment is a further description of specific embodiment two. In step one, the nucleating agent is Fe 2 o 3 、TiO 2 or P 2 o 5 , the flux is SiO 2 , CaO or glass slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com