Preparation method for three-dimensional woven fiber reinforced ceramic matrix composite

A technology of structural fibers and composite materials, applied in the field of preparation of ceramic matrix composite materials, can solve the problems of small molecule overflow, low interlaminar shear strength, long preparation period, etc., to increase the interlaminar shear strength, facilitate large-scale Production, the effect of reducing delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

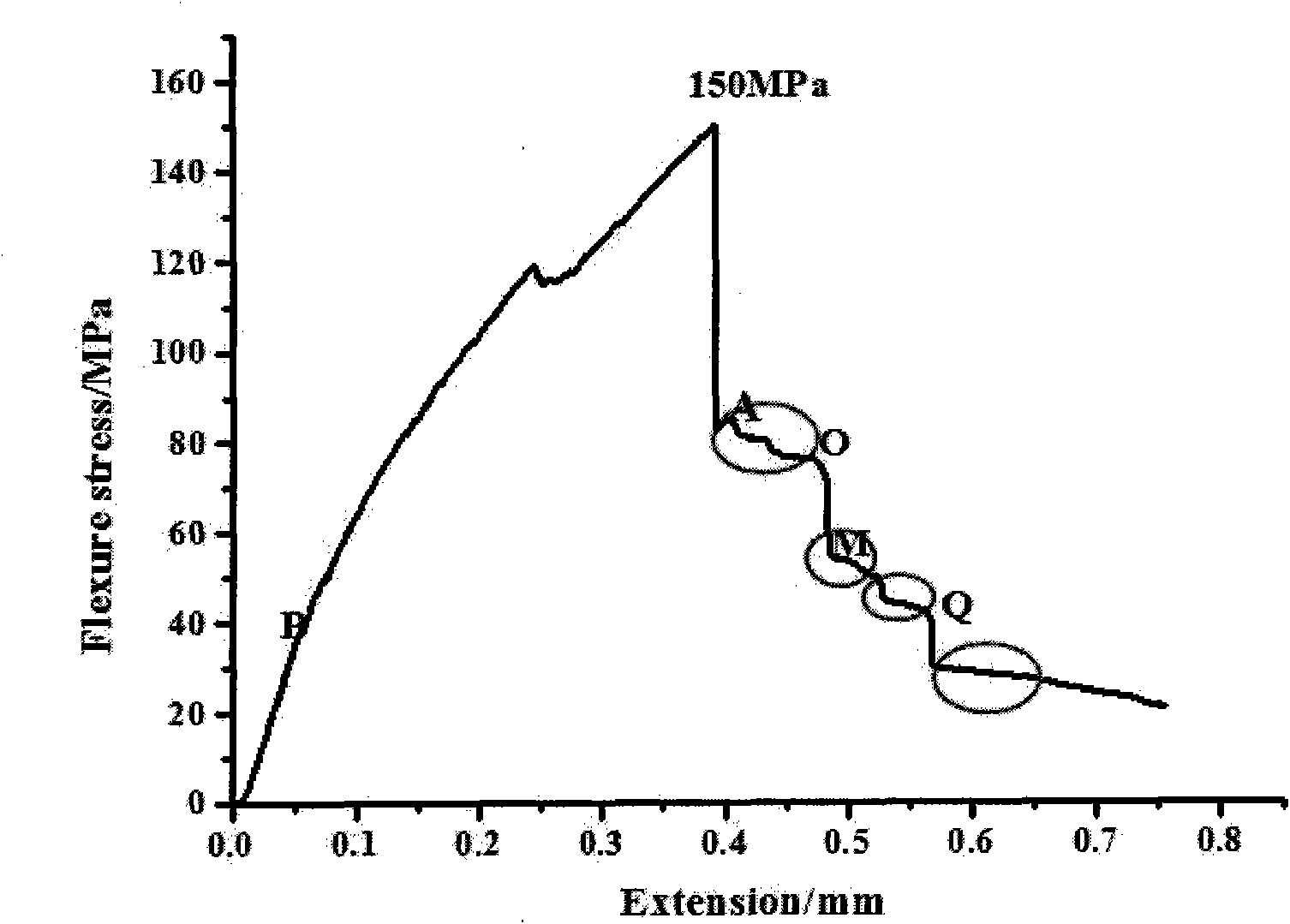

[0036] A three-dimensional woven structure carbon fiber reinforced silica ceramic matrix composite material can be obtained by the following method:

[0037] (1) Weigh 400g fused silica powder, prepare slurry by deionized water and powder mass ratio of 2:3, add 1.5vol.% binder carboxymethylcellulose (CMC) and dispersant isopropanol at the same time ; Put it into a ball mill with a ball-to-material ratio of 2:3 for ball milling for 3 hours, the grinding medium is agate balls, and the obtained kinematic viscosity is 120mm 2 / s silica ceramic slurry.

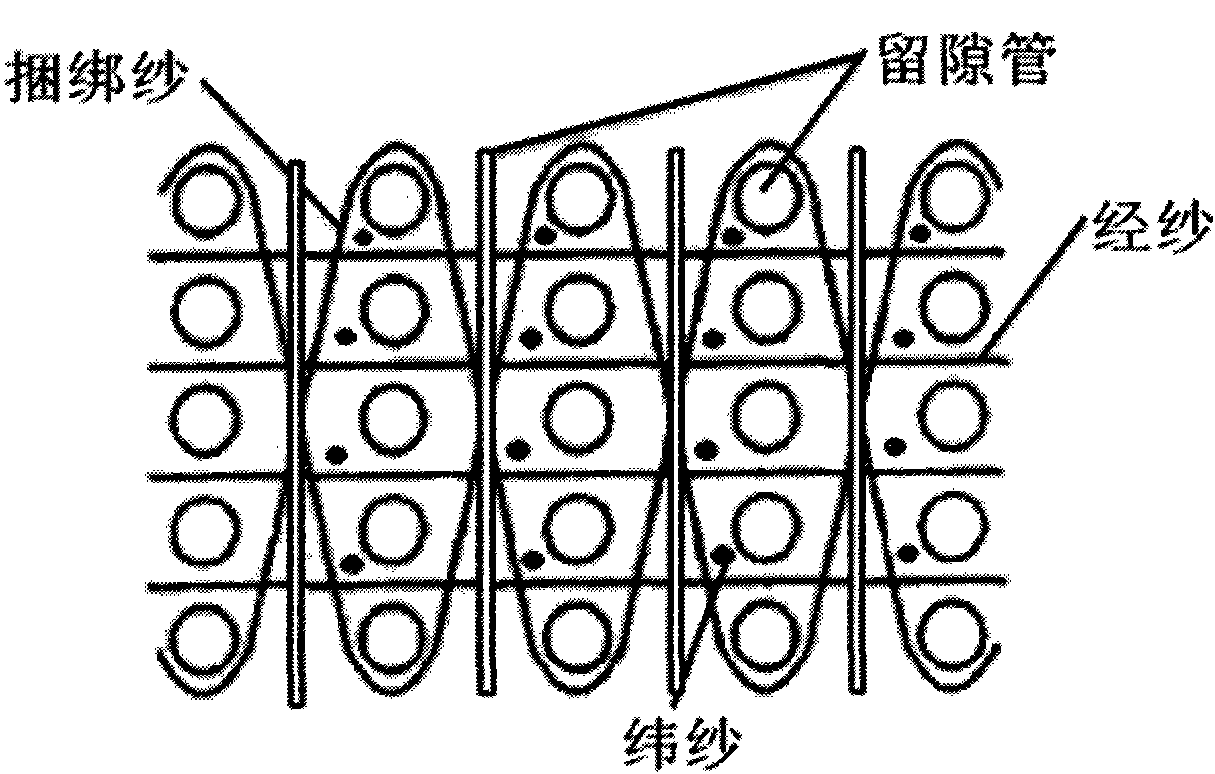

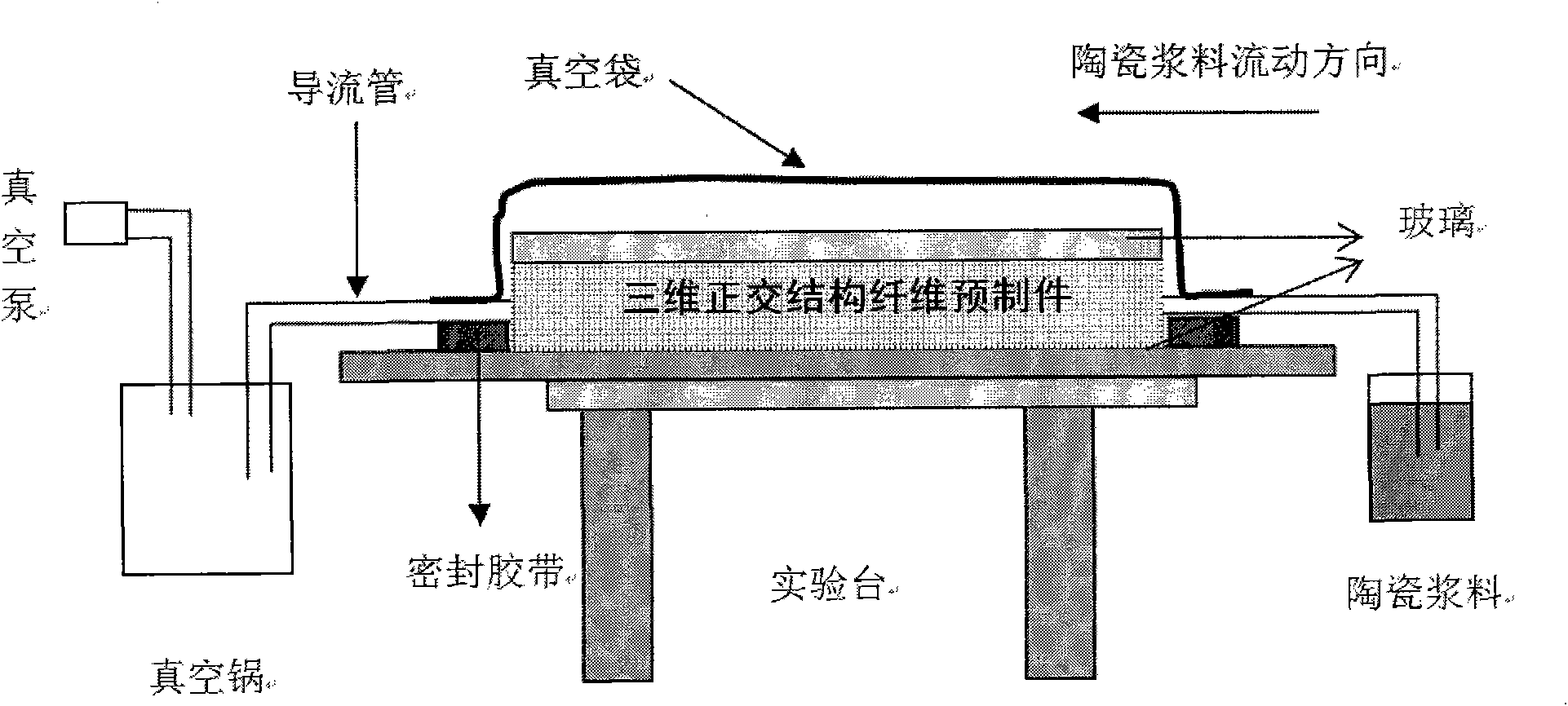

[0038](2) Choose carbon fiber with a specification of 3K to weave a three-dimensional woven structure carbon fiber reinforced silica ceramic prefabricated part consisting of 3 layers of warp yarn and 4 layers of weft yarn, with a warp density of 5 threads / cm and a weft density of 5 threads / cm. Before each weft insertion, the silica ceramic slurry is fully filled in the gap between the yarns by coating and pouring methods, and a "g...

Embodiment 2

[0043] A three-dimensional woven structure carbon fiber reinforced alumina ceramic matrix composite material can be obtained by the following method:

[0044] (1) Weigh 360g of alumina powder, prepare slurry by deionized water and powder mass ratio of 2:3, add 1.5vol.% binder carboxymethylcellulose (CMC) and dispersant isopropanol at the same time ; put into a ball milling tank with a ball-to-material ratio of 2:3 for ball milling for 3 hours, the grinding medium is agate balls, and the obtained kinematic viscosity is 100mm 2 / s alumina ceramic slurry.

[0045] (2) Choose carbon fiber with a specification of 3K to weave a three-dimensional woven structure carbon fiber reinforced alumina ceramic prefabricated part consisting of 3 layers of warp yarn and 4 layers of weft yarn, with a warp density of 5 threads / cm and a weft density of 5 threads / cm. Before each weft insertion, the alumina ceramic slurry is fully filled in the gap between the yarns by coating and pouring methods, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com