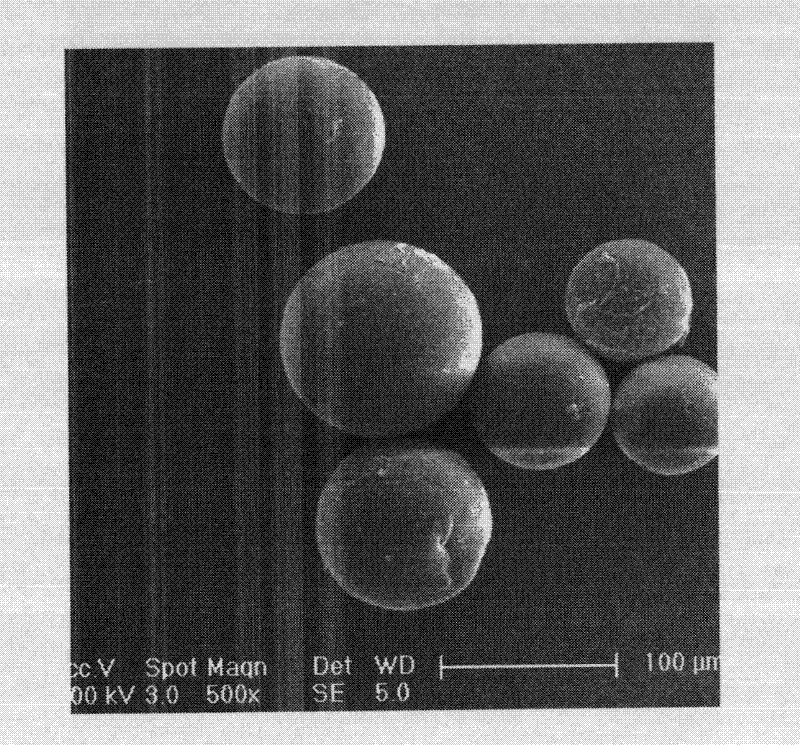

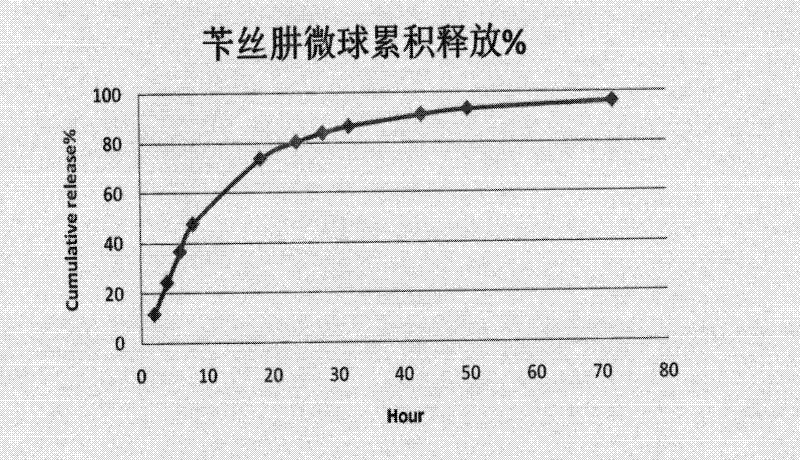

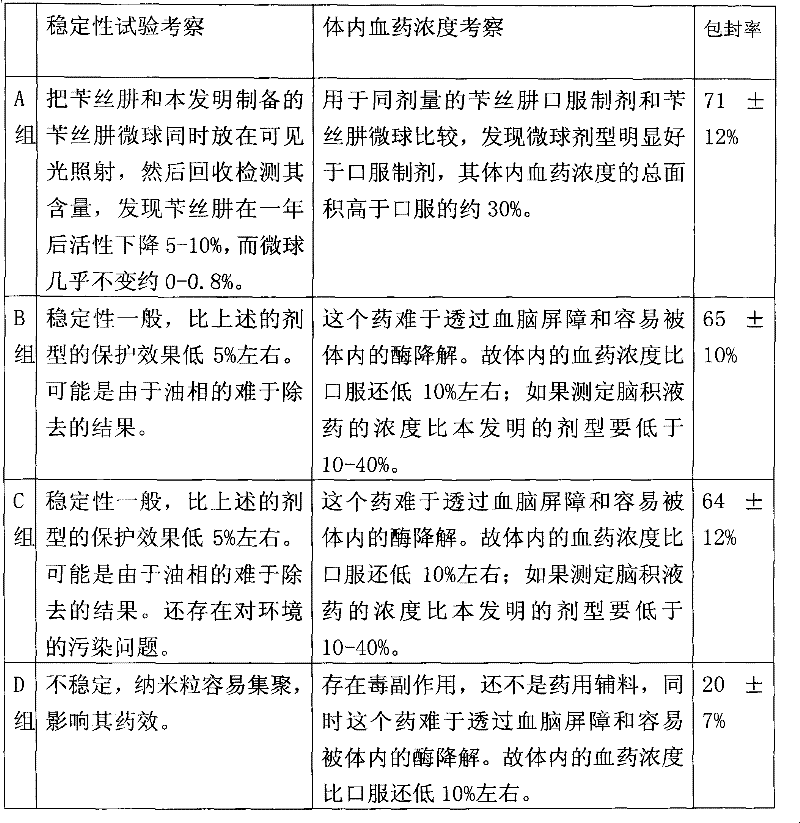

Long-acting benserazide sustained release microsphere composition and preparation method thereof

A technology of slow-release microspheres and benserazide, which is applied in drug combinations, medical preparations of non-active ingredients, pharmaceutical formulations, etc., can solve problems with movement and memory, and there is no relevant literature report on the preparation of benserazide microspheres method, inconvenience and other problems, to achieve the effect of good redispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] ①Preparation of benserazide solution

[0028] a) 100mg of benserazide was prepared into an aqueous solution with a concentration of 2.5% by weight;

[0029] ②Preparation of benserazide sustained-release microsphere composition

[0030] (a) The polylactic acid (PLA, molecular weight is 90,000-140,000) that takes by weighing 37.5mg is mixed with the organic solution that is 15% dichloromethane and weighs 0.5mL above-mentioned ① benserazide solution and mixes and Stir, vortex or sonicate for 1-5 minutes to form a uniform suspension, that is, a water-in-oil (W / O) emulsion; the theoretical percentage of benserazide prepared into sustained-release microspheres is 15%.

[0031] (b) adding the emulsion obtained in step (a) to 10 mL of an aqueous solution of 5% sodium chloride and 1% polyethylene glycol (the molecular weight of PVA is 146,000-186,000, alcoholysis degree 98-99%) with a weight percent concentration and Stir, vortex or sonicate for 0.1-5 minutes to form double em...

Embodiment 2

[0039] ①Preparation of benserazide solution

[0040] a) 100mg of benserazide was prepared into an aqueous solution with a concentration of 2.5% by weight;

[0041] ②Preparation of benserazide sustained-release microsphere composition

[0042] (a) 295mg of polylactic acid (PLA, molecular weight: 90,000-140,000) was weighed to prepare an organic solution of 15% dichloromethane by weight, and 0.2mL of the above-mentioned benserazide solution was mixed and stirred. Vortex or sonicate for 1-5 minutes to form a uniform suspension, that is, a water-in-oil (W / O) emulsion; the theoretical percentage of benserazide prepared into sustained-release microspheres is 1%.

[0043] (b) adding the emulsion obtained in step (a) to 10 mL of an aqueous solution of 5% sodium chloride and 1% polyethylene glycol (the molecular weight of PVA is 146,000-186,000, alcoholysis degree 98-99%) with a weight percent concentration and Stir, vortex or sonicate for 0.1-5 minutes to form double emulsion;

[0...

Embodiment 3

[0051] ①Preparation of benserazide solution

[0052] a) 100mg of benserazide was prepared into an aqueous solution with a concentration of 2.5% by weight;

[0053] ②Preparation of benserazide sustained-release microsphere composition

[0054] (a) 37.5 mg of polylactic-glycolic acid (PLGA, molecular weight 6000-500,000) was weighed to prepare an organic solution of 15% dichloromethane by weight and 0.5 mL of the above-mentioned ① benserazide solution Mix and stir, vortex or sonicate for 1-5 minutes to form a uniform suspension, that is, a water-in-oil (W / O) emulsion; the theoretical percentage of benserazide prepared into sustained-release microspheres is 35%.

[0055] (b) adding the emulsion obtained in step (a) to 10 mL of an aqueous solution of 5% sodium chloride and 1% polyethylene glycol (the molecular weight of PVA is 146,000-186,000, alcoholysis degree 98-99%) with a weight percent concentration and Stir, vortex or sonicate for 0.1-5 minutes to form double emulsion;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com