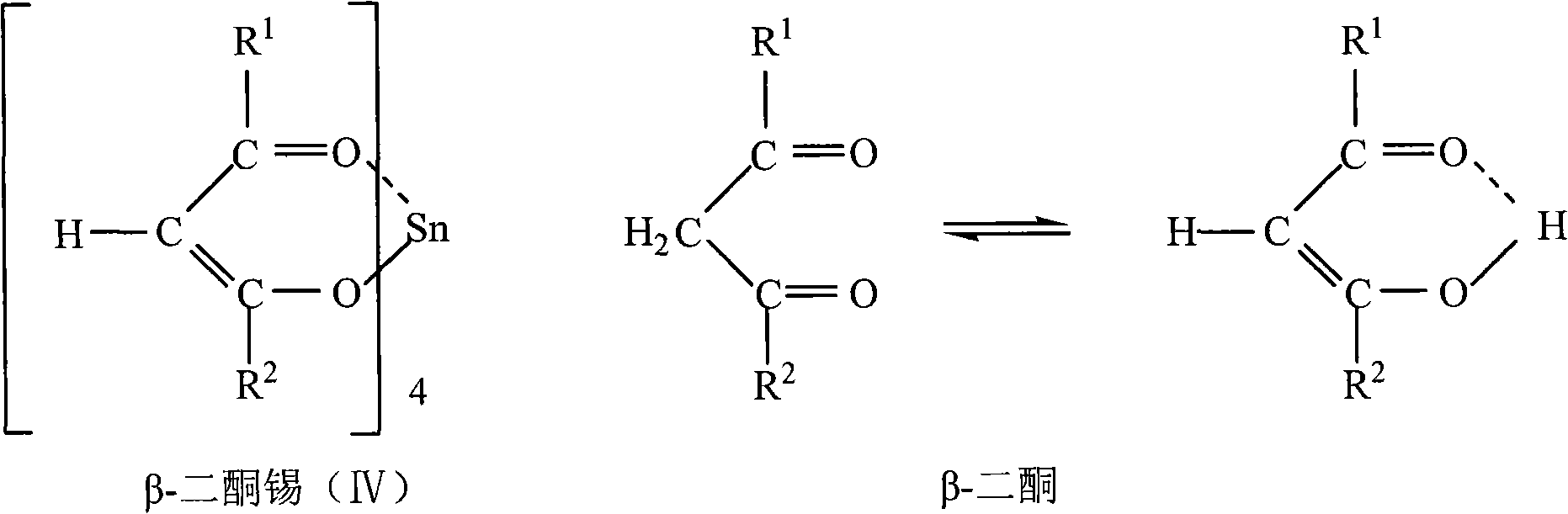

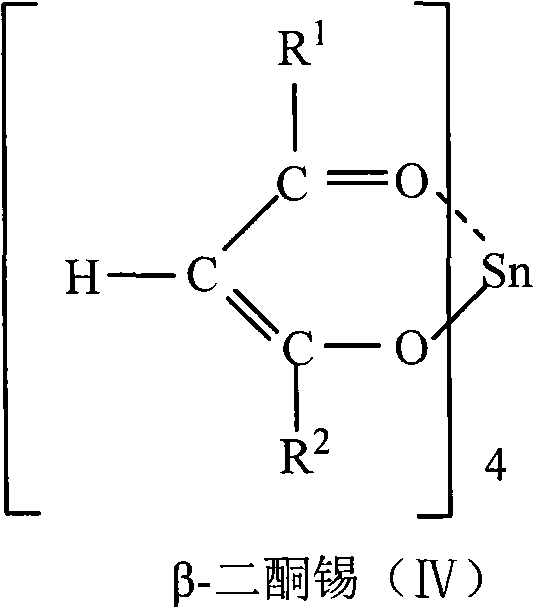

Preparation method of beta-diketone tine (IV) compound

A manufacturing method and compound technology, applied in the preparation of aldehyde/ketone chelates, organic chemistry, etc., can solve the problems of producing β-diketone tin that have not been seen, achieve no environmental pollution, the preparation method is simple to operate, and the raw materials are easy to obtain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 0.02mol stannous chloride and 30mL distilled water into a 250mL reaction bottle, add 0.06mol acetylacetone (Hacac) while stirring, after stirring for 10min, slowly add 1mol / L ammonia solution dropwise, adjust the pH of the solution to 7-8 , continue stirring for 3h. Filtrate under reduced pressure, recrystallize the filter cake with ethanol, and dry the filter cake in vacuum at 40°C for 2 hours to obtain a white powder of tin acetylacetonate with a yield of 91.3%.

Embodiment 2

[0023] Add 0.02mol stannous chloride and 30mL ethanol into a 250mL reaction bottle, add 0.06mol acetylacetone (Hacac) while stirring, after stirring for 10min, slowly add 1mol / L ammonia solution dropwise, adjust the pH of the solution to 7-8 , continue stirring for 3h. Filtrate under reduced pressure, recrystallize the filter cake with ethanol, and dry the filter cake at 80°C for 2 hours to obtain a white powder of tin acetylacetonate with a yield of 94.7%.

Embodiment 3

[0025] Add 0.02mol stannous bromide and 30mL ethanol in a 250mL reaction flask, add 0.06mol acetylacetone (Hacac) while stirring, heat to reflux, slowly add 1mol / L aqueous urea solution dropwise, and adjust the pH of the solution to 7.5-8.5, Continue to stir for 1 h, after cooling, filter under reduced pressure, recrystallize the filter cake with ethanol, dry the filter cake with an infrared lamp for 1.5 h, and obtain a white powder of tin acetylacetonate with a yield of 95.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com