Method for preparing hollow fiber membranes by using thermally induced phase separation (TIPS) process

A technology of fiber membrane and thermotropic phase, applied in the field of polyvinylidene fluoride porous hollow fiber membrane and its preparation method, can solve the problems of unsatisfactory ultra- and microfiltration membrane effects and uneven distribution of membrane pore sizes that cannot meet the requirements of industrial production and other problems, to achieve the effect of good chemical cleaning resistance and hydrophilicity, excellent anti-pollution ability, and good anti-pollution characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

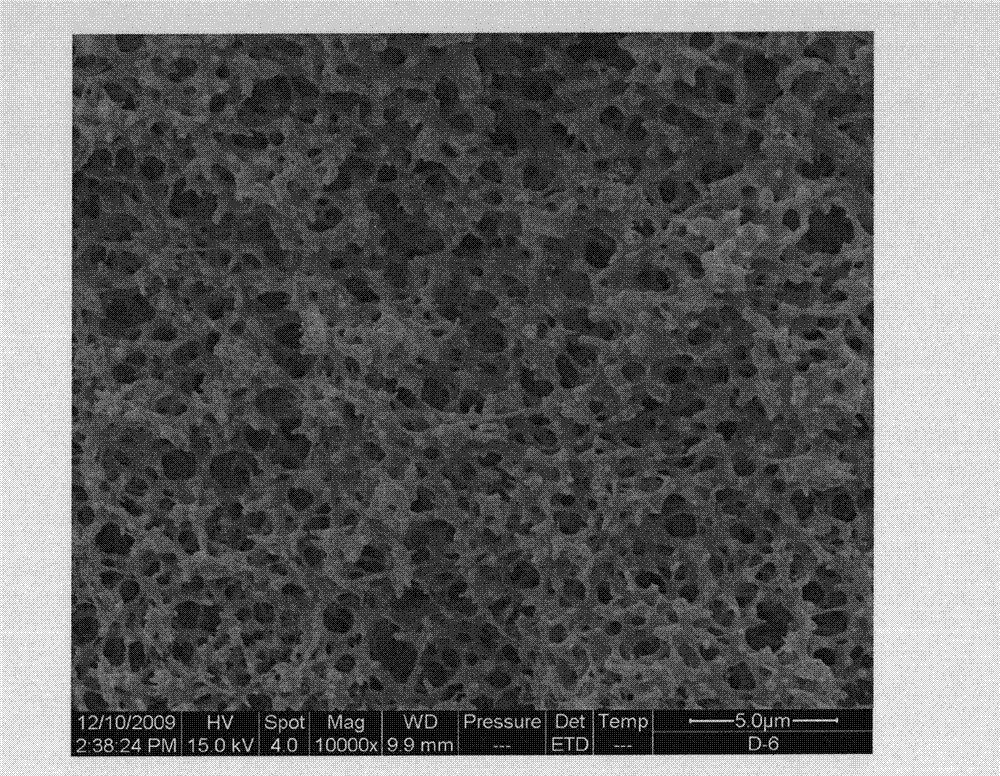

Image

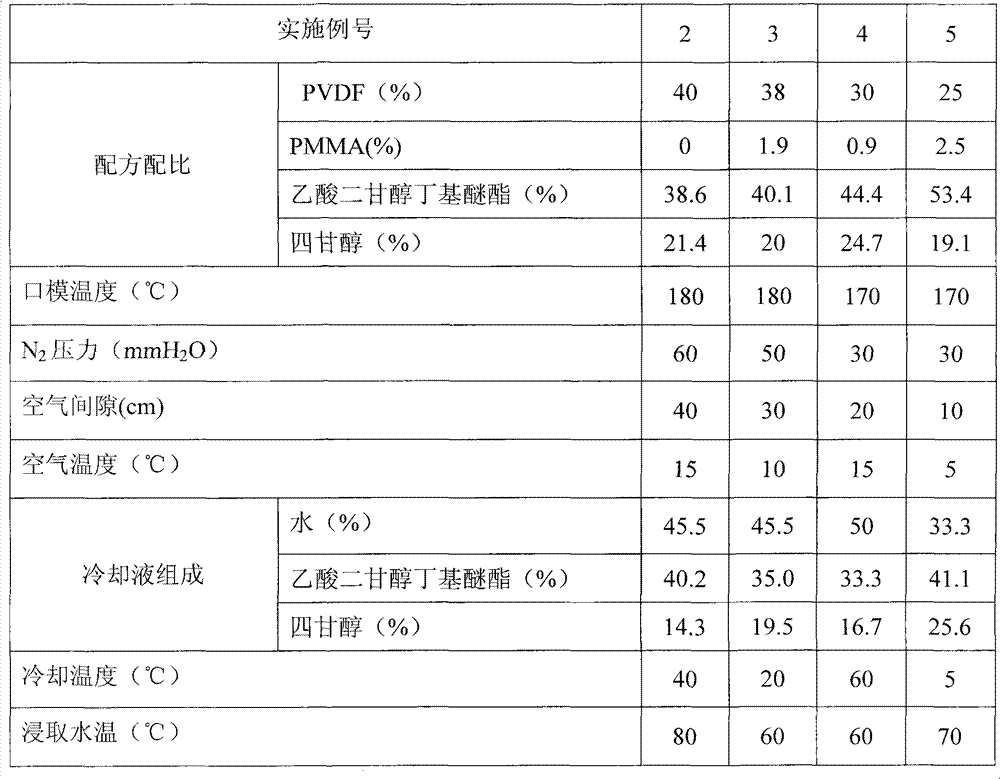

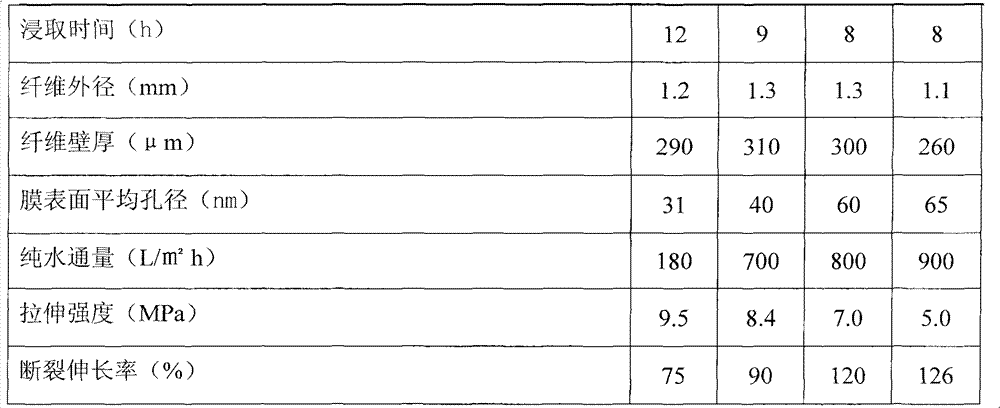

Examples

Embodiment 1

[0051] A blended polymer composed of PVDF drying resin with a mass percentage of 35% and polymethyl methacrylate drying resin with a mass percentage of 2.1%, added to diethylene glycol butyl ether acetate and tetraethylene glycol In the mixed solvent, the mass percentage of diethylene glycol butyl ether acetate is 38.7%, and the mass percentage of tetraethylene glycol is 24.2%. The above mixture was added into a stirred tank, stirred and dissolved at a temperature of 180° C. and a rotational speed of 120 rpm for 24 hours, and then cooled and granulated in air to obtain a blended raw material. The previously prepared blend was fed into the twin-screw extruder at a feed rate of 8 kg / h. The temperatures in zones 1-8 of the extruder were 125°C, 140°C, 155°C, 170°C, 180°C, 180°C, 180°C, 170°C respectively, and the screw speed was 120 rpm. After the mixed material is melted and extruded in a twin-screw machine, it is extruded through a filter and a spinning pump into a four-hole an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com