Method for low-temperature synthesis of silicon carbide from agricultural wastes

An agricultural waste, silicon carbide technology, applied in the direction of solid waste removal, etc., can solve the problems of increasing the production cost of silicon carbide, increasing energy consumption, and high equipment requirements, and achieving low price, low equipment investment cost, and low density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

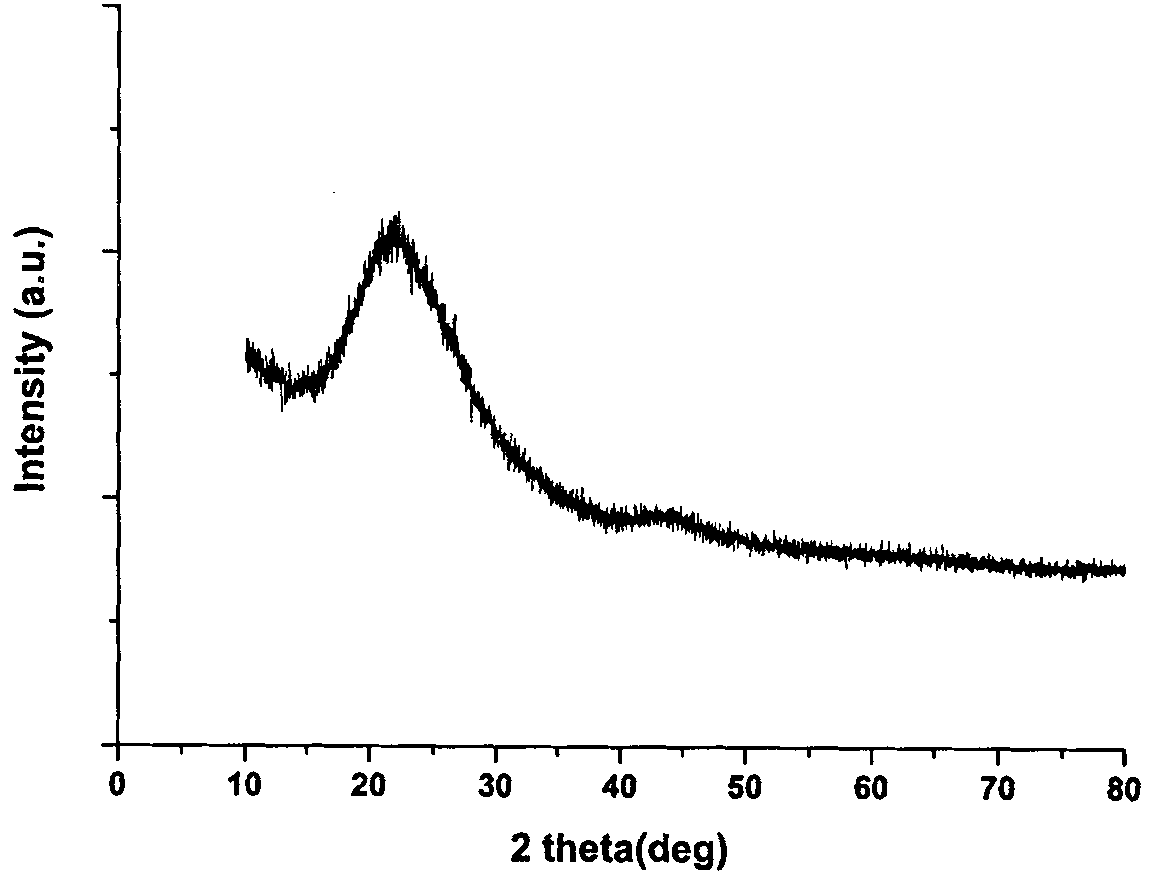

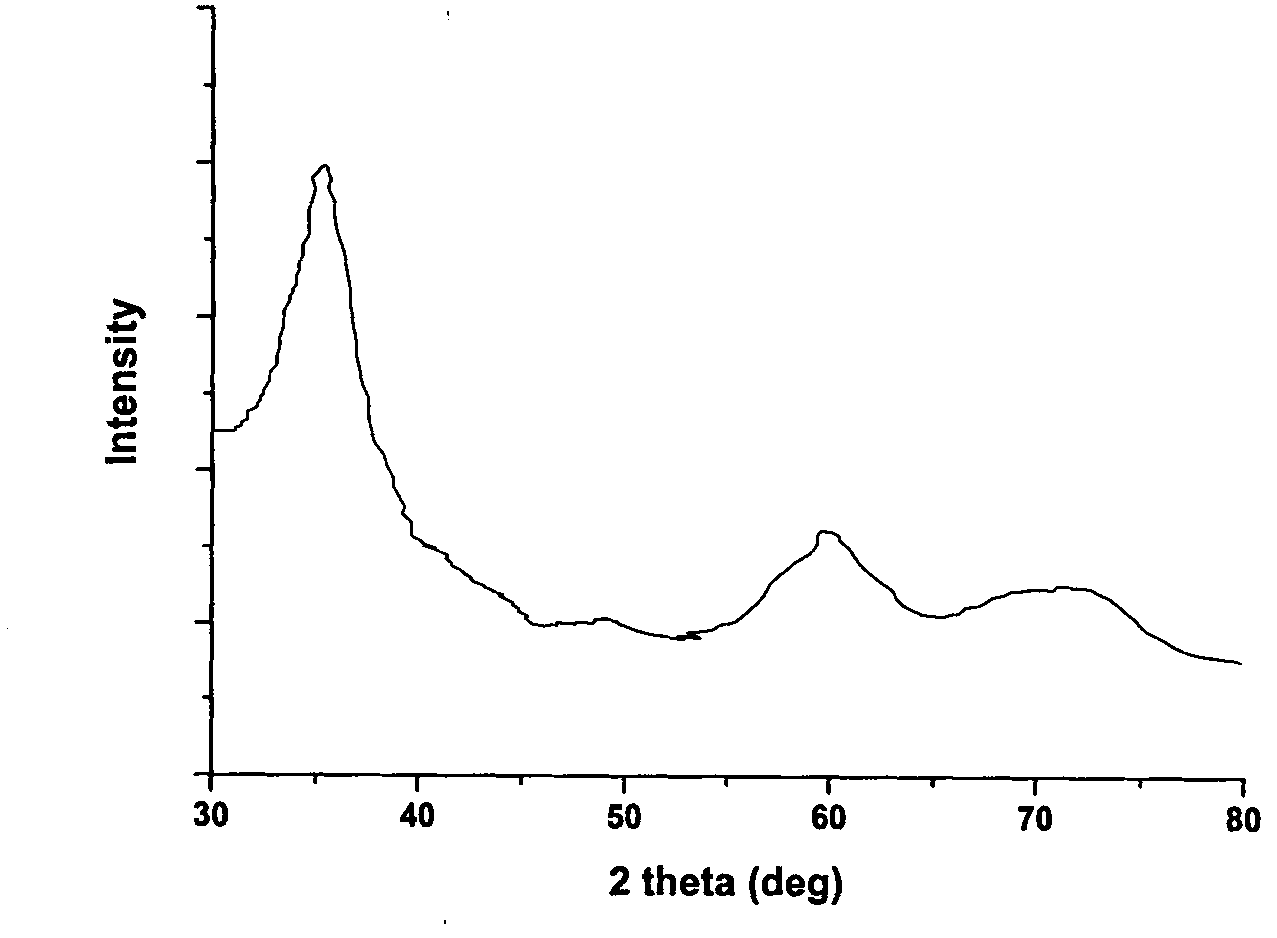

Image

Examples

specific Embodiment approach

[0015] The invention proposes a method for synthesizing silicon carbide from agricultural waste at low temperature. The preparation process is simple and the production cost is low. The specific implementation method comprises the following steps:

[0016] The first step of preparation is to pyrolyze the agricultural waste under the condition of 400-900 degrees in an inert atmosphere. During the pyrolysis process, the organic matter in agricultural waste is decomposed by high temperature, and due to the protective effect of inert gases such as nitrogen, carbon dioxide, argon, etc., the main pyrolysis product of agricultural waste is SiO 2 and C.

[0017] The second step of preparation is to fully mix the pyrolysis product of agricultural waste with metal reducing agent powder such as metal magnesium powder, metal aluminum powder and metal zinc powder. The mixture is heated to 500-800 degrees under the protection of isolated air or inert gas, and reacts for 15-120 minutes. Th...

Embodiment 1

[0024] Embodiment 1: Taking rice husk as raw material

[0025] 1) 100 grams of rice husks are fully pulverized, put into a 900-degree furnace and calcined for 15 minutes under the protection of an inert gas to obtain pyrolysis products of rice husks;

[0026] 2) Fully mix the pyrolysis product with 2 grams of metal reducing agent powder, put the obtained mixture into a furnace, and calcine at 500°C for 120 minutes in isolation of air or under the protection of an inert gas;

[0027] 3) Add the product of step 2) into 1M non-oxidizing acid solution, and soak for 15 minutes; the product is centrifuged, washed with water, and dried in solid phase to obtain silicon carbide powder.

Embodiment 2

[0028] Embodiment 2: Taking rice straw as raw material

[0029] 1) Fully pulverize 100 grams of rice straw, put it into a 400-degree furnace and calcinate for 120 minutes under the protection of an inert gas to obtain a pyrolysis product of rice straw;

[0030] 2) Fully mix the pyrolysis product with 10 grams of metal reducing agent powder, put the obtained mixture into a furnace, and calcine at 800°C for 15 minutes in isolation of air or under the protection of an inert gas;

[0031] 3) Add the product of step 2) into a 0.05M non-oxidizing acid solution, and soak for 120 minutes; the product is centrifuged, washed with water, and dried in solid phase to obtain silicon carbide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com