Silicone-polyether copolymer systems and process for preparing them by means of an alkoxylation reaction

A technology of polyether copolymer and polysiloxane, which is applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve the problems of catalyst dosage and reaction time increase, uneconomical preparation, etc., and achieve a high reaction rate Falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

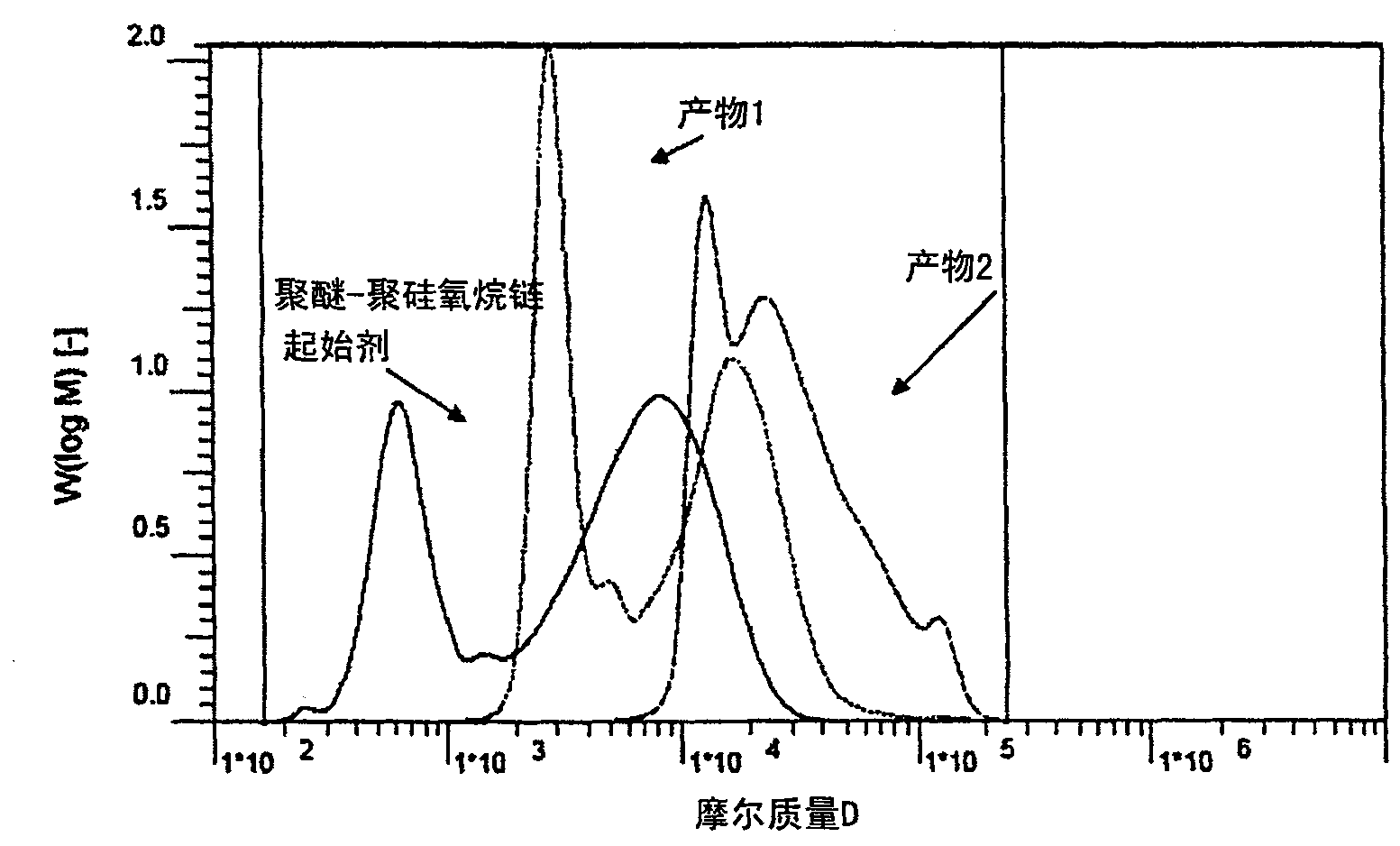

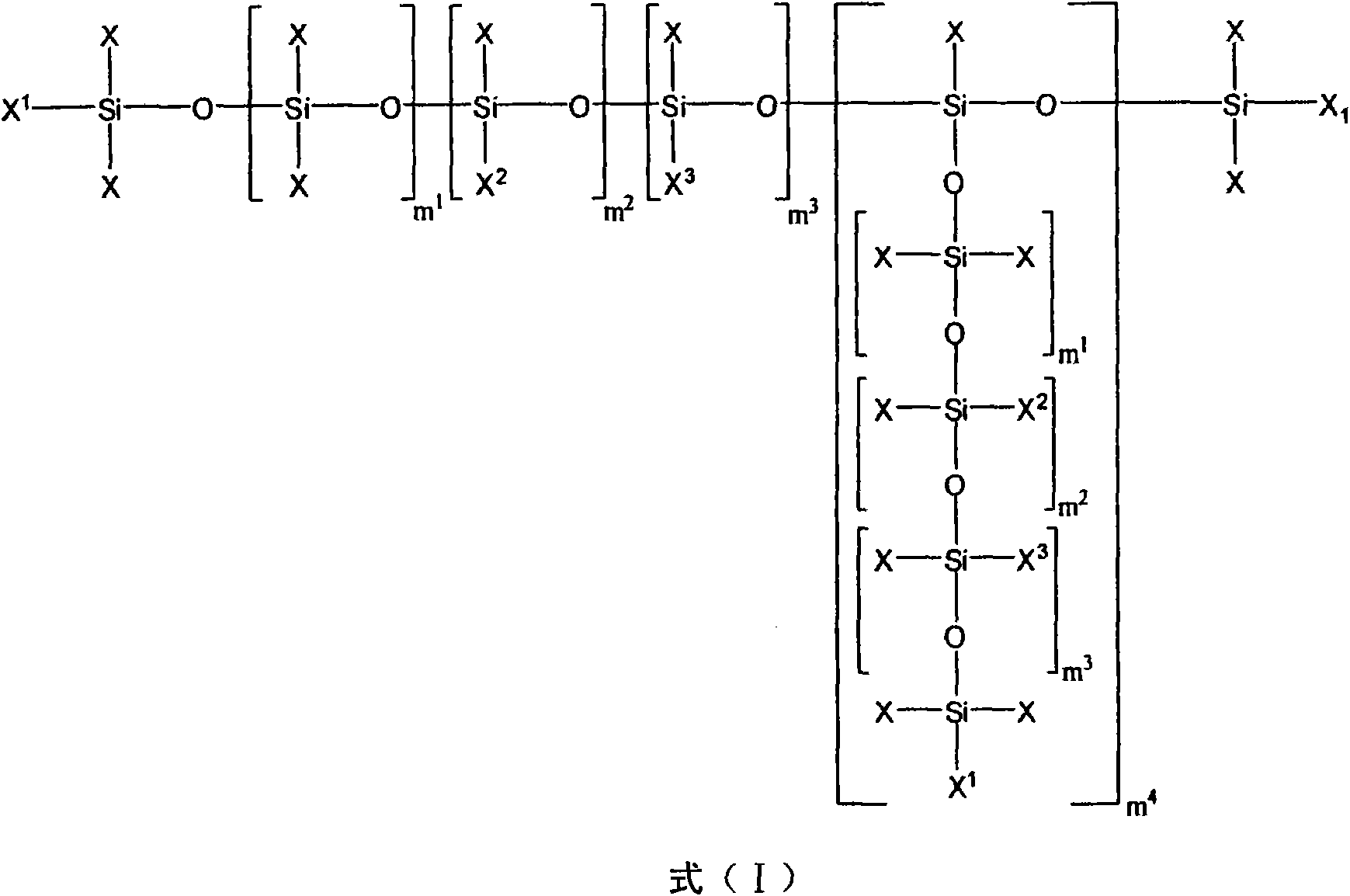

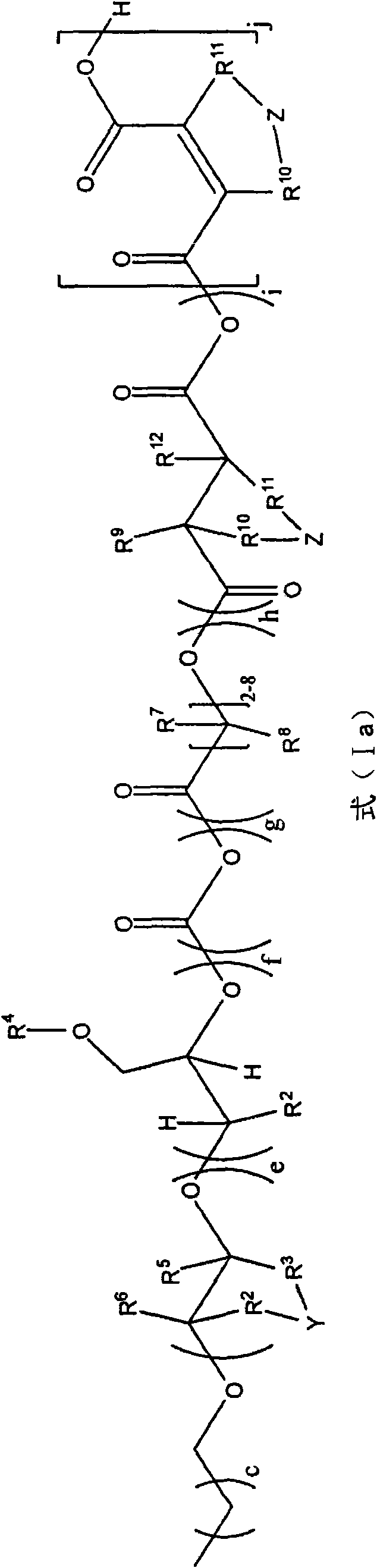

[0119] As a chain starter, use has the structure m 1 =20,m 2 = 5, m 3 =m 4 =0,X=X 1 =Methyl polyether-polysiloxanes of the formula (I) used in excess according to the prior art with an average molar mass of 800 g / mol and containing 36% by weight of ethylene oxide units and 64% by weight of rings OH-terminated allyl polyethers of oxypropylene units, previously prepared by hydrosilylation of hydrogen siloxanes.

[0120] Under nitrogen, 200.0 g of this polyether-polysiloxane (containing 15-20% by weight of excess polyether with an average molar mass of 800 g / mol) and 0.10 g of hexacyanocobaltate were introduced into a 3-liter autoclave zinc DMC catalyst and heated to 130°C with stirring. The reactor was pumped down to an internal pressure of 30 mbar, so that any volatile constituents present were removed by distillation. To activate the DMC catalyst, a portion of 40.0 g of propylene oxide was added. 15 minutes and after the start of the reaction (decrease in reactor intern...

Embodiment 2

[0123] As a chain starter, used is prepared by hydrosilylation and has the structure m 1 =61.5; m 2 = 1.6; m 3 = 4.9; m 4 =0,X=X 1 =Methyl polyether-polysiloxane, which uses a mass ratio of 41:17:42 of the following composition of terminal OH-functionalized allyl polyether and two methyl-terminated allyl polyethers Mixture preparation:

[0124] a) 18% by weight of ethylene oxide, 82% by weight of propylene oxide, 1400g / mol, R in formula (Ib) 13 = methyl,

[0125] b) 74% by weight of ethylene oxide, 26% by weight of propylene oxide, 3800g / mol, R in formula (Ib) 13 = methyl,

[0126] c) 42% by weight ethylene oxide, 58% by weight propylene oxide, 3800 g / mol.

[0127] Under nitrogen, 162.0 g of this polyether-polysiloxane (containing about 20% by weight excess polyether mixture) and 0.024 g of zinc hexacyanocobaltate DMC catalyst were added to a 3-liter autoclave and, under stirring, Heat to 130°C. The reactor was pumped down to an internal pressure of 30 mbar, so that ...

Embodiment 3

[0130] As a chain starter, used is prepared by hydrosilylation and has the structure m 1 =61.5; m 2 = 6.5; m 3 =m 4 =0,X=X 1 =methyl polyether-polysiloxane prepared using a mixture of three terminal OH-functionalized allyl polyethers in the mass ratio 36:6:58 of the composition:

[0131] a) 10% by weight of ethylene oxide, 90% by weight of propylene oxide, 1500 g / mol,

[0132] b) 58% by weight ethylene oxide, 42% by weight propylene oxide, 1300 g / mol,

[0133] c) 42% by weight ethylene oxide, 58% by weight propylene oxide, 3800 g / mol.

[0134] Under nitrogen, 159.0 g of this polyether-polysiloxane (containing about 20% by weight of excess polyether mixture) and 0.031 g of zinc hexacyanocobaltate DMC catalyst were added to a 3-liter autoclave and, under stirring, Heat to 130°C. The reactor was pumped down to an internal pressure of 30 mbar, so that any volatile constituents present were removed by distillation. To activate the DMC catalyst, a portion of 21.0 g of propyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com