Method for preparing paramagnetic polyphosphazene nanotube magnetic resonance imaging contrast agent

A technology of magnetic resonance imaging and polyphosphazene, which is applied in the directions of nuclear magnetic resonance/magnetic resonance imaging contrast agents, preparations for in vivo experiments, pharmaceutical formulations, etc. Fibrosis and other problems, to achieve the effects of good biocompatibility and degradability, low cost and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

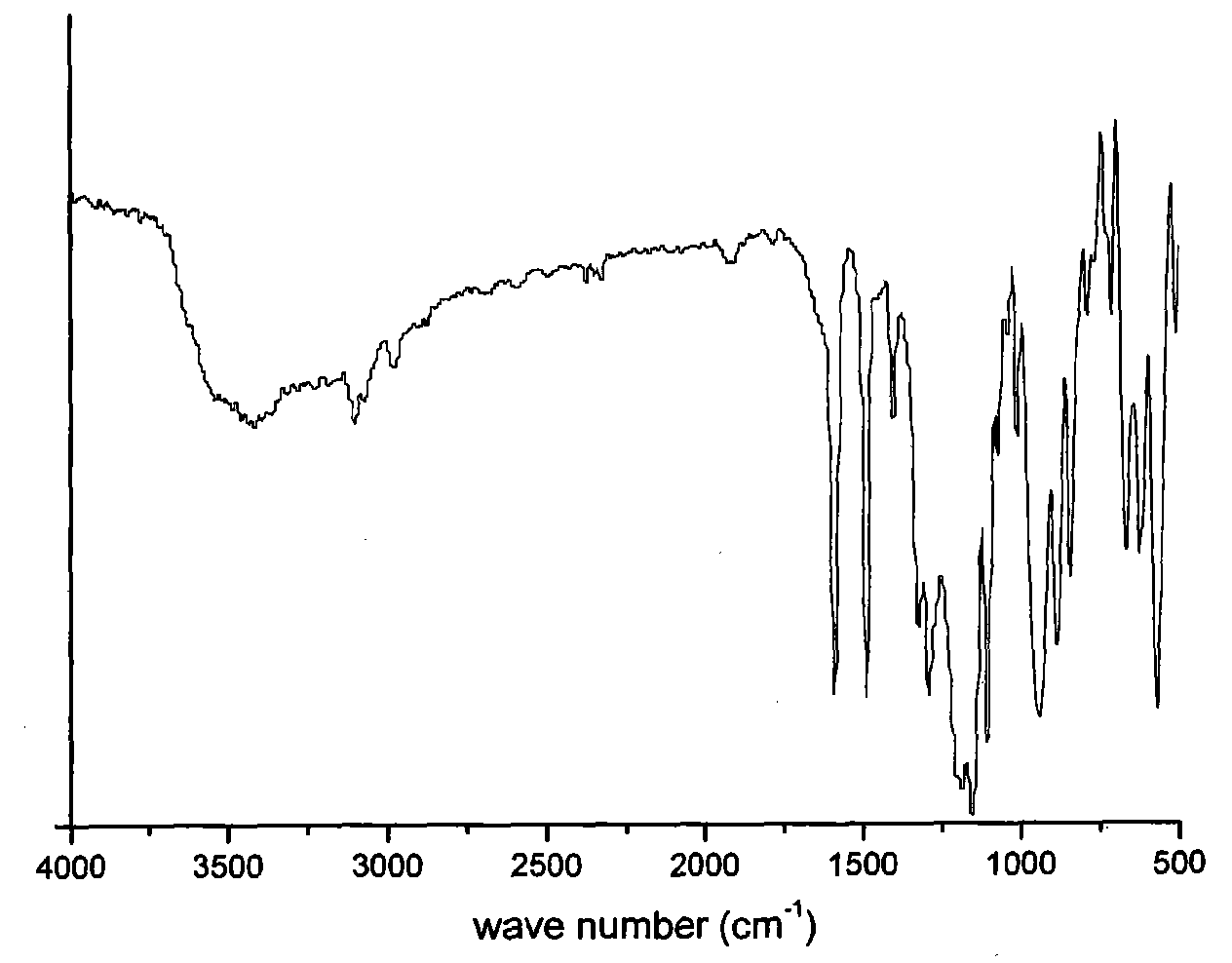

[0019] Add 5 grams (14.4 millimoles) of hexachlorocyclotriphosphazene and 10.8 grams (43.2 millimoles) of 4,4'-dihydroxydiphenylsulfone in a 1000 milliliter flask, then add 400 milliliters of anhydrous tetrahydrofuran, stir to dissolve, and then Add 8.7 g (86.4 mmol) of triethylamine in 150 ml of anhydrous tetrahydrofuran solution into the above reactor, and at 25 ° C, use an ultrasonic cleaner to vigorously stir and react for half an hour. After the reaction is completed, filter the crude The product was washed three times with tetrahydrofuran, then three times with deionized water, and finally dried in a vacuum oven for 24 hours to obtain 12.5 g of cross-linked polyphosphazene nanotubes, with a yield of 93% based on hexachlorocyclotriphosphazene.

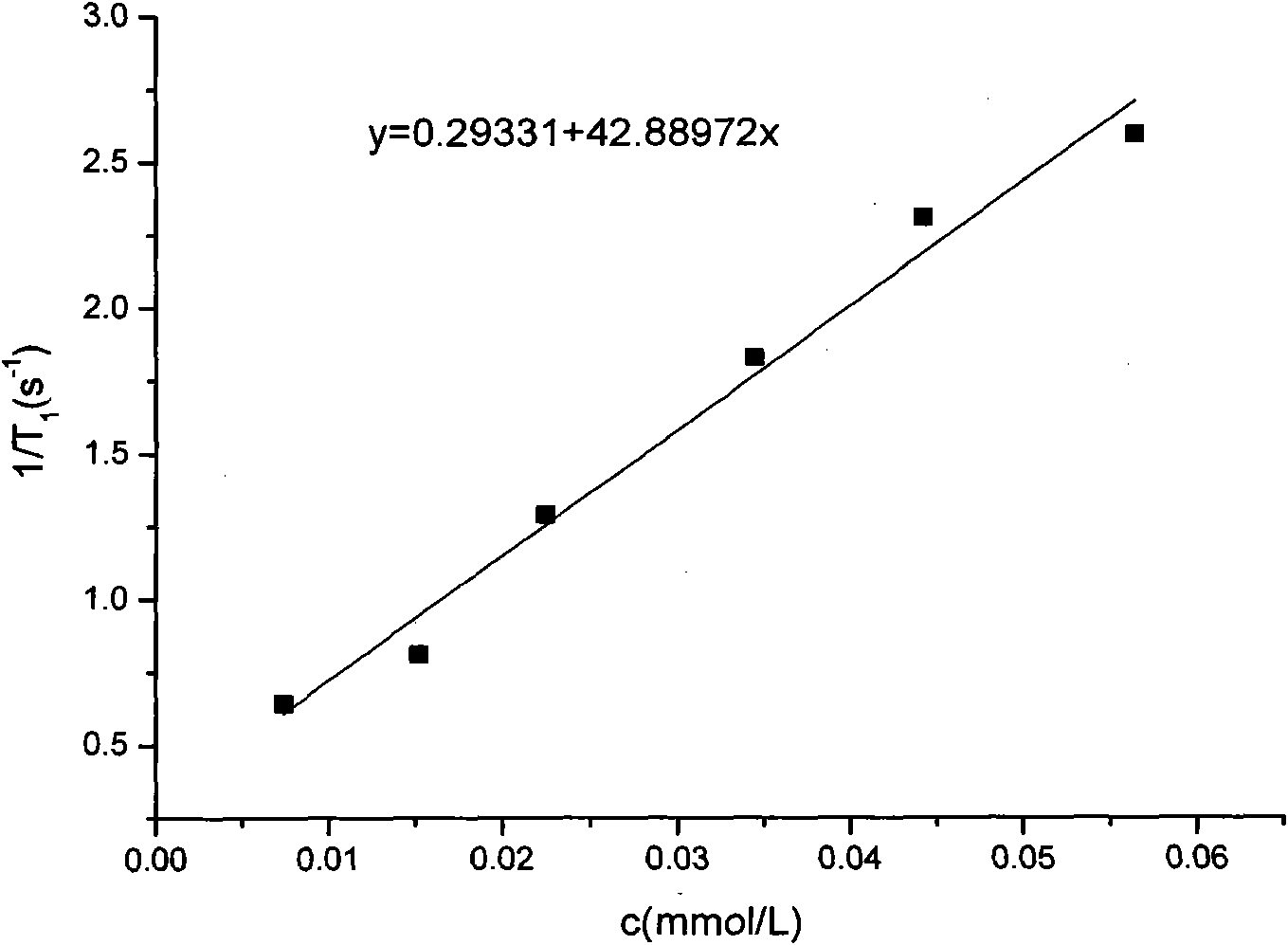

[0020] Add 8.8 grams of synthesized cross-linked polyphosphazene nanotubes to a 500 ml flask, add 350 ml of deionized water, stir vigorously with an ultrasonic cleaner for half an hour, add GdCl 3 ·6H 2 3.75 g of O solid was reac...

example 2

[0026]Add 5 grams (14.4 millimoles) of hexachlorocyclotriphosphazene and 10.8 grams (43.2 millimoles) of 4,4'-dihydroxydiphenylsulfone in a 1000 milliliter flask, then add 400 milliliters of anhydrous tetrahydrofuran, stir to dissolve, and then Add 8.7 g (86.4 mmol) of triethylamine in 150 ml of anhydrous tetrahydrofuran solution into the above reactor, and at 25 ° C, use an ultrasonic cleaner to vigorously stir and react for half an hour. After the reaction is completed, filter the crude The product was washed three times with tetrahydrofuran, then washed three times with deionized water, and finally dried in a vacuum oven for 24 hours to obtain cross-linked polyphosphazene nanotubes.

[0027] Add 8.8 grams of synthesized cross-linked polyphosphazene nanotubes to a 500 ml flask, add 350 ml of deionized water, stir vigorously with an ultrasonic cleaner for half an hour, add MnCl 2 2.45 g of solids were reacted for 6 hours at 25° C. with an ultrasonic power of 240 watts. After...

example 3

[0029] Add 5 grams (14.4 millimoles) of hexachlorocyclotriphosphazene and 10.8 grams (43.2 millimoles) of 4,4'-dihydroxydiphenylsulfone in a 1000 milliliter flask, then add 400 milliliters of anhydrous tetrahydrofuran, stir to dissolve, and then Add 8.7 g (86.4 mmol) of triethylamine in 150 ml of anhydrous tetrahydrofuran solution into the above reactor, and at 25 ° C, use an ultrasonic cleaner to vigorously stir and react for half an hour. After the reaction is completed, filter the crude The product was washed three times with tetrahydrofuran, then washed three times with deionized water, and finally dried in a vacuum oven for 24 hours to obtain cross-linked polyphosphazene nanotubes.

[0030] Add 8.8 grams of synthesized cross-linked polyphosphazene nanotubes to a 500 ml flask, add 350 ml of deionized water, stir vigorously with an ultrasonic cleaner for half an hour, add FeCl 2 2.55 g of solids were reacted for 6 hours at 25° C. with an ultrasonic power of 240 watts. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com