Crystallization of amorphous silicon film as well as manufacture method and device of poly-silicon film

An amorphous silicon thin film and crystallization technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of complex laser crystallization process, difficult maintenance, affecting TFT uniformity, etc., to improve electron mobility , Save the cost of use, eliminate the effect of lattice defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

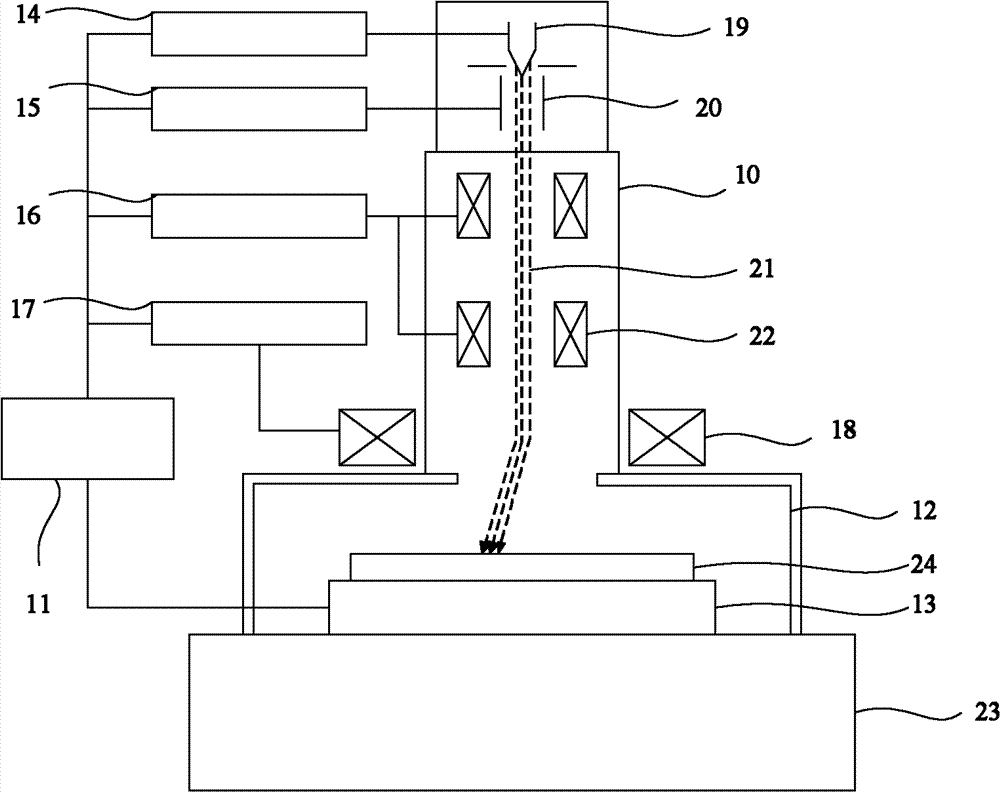

[0040] In this example, the electron beam crystallization device is as image 3 As shown, it mainly includes: an electron optical system 10, a computer control system 11, a vacuum workpiece chamber 12 and a workpiece console 13 placed in the workpiece chamber, and the vacuum workpiece chamber is placed on a shockproof table 23. The electron optical system is placed above the workpiece chamber and works in electron beam scanning mode. Computer control system 11 controls high-voltage power supply 14 , grid power supply 15 , electron lens power supply 16 , deflection coil control 17 and workpiece console 13 .

[0041] Among them, the electron optical system is composed of a cathode 19, a grid 20, an electron lens 22, and a deflection coil 18. The cathode emits an electron beam 21, the grid controls the on-off of the electron beam, the electron lens realizes the focusing of the electron beam, and the deflection coil is fixed on the workpiece. The outer or inner walls of the chamb...

Embodiment 2

[0048] In this example, the electron beam crystallization device is as Figure 4 As shown, it mainly includes: an electron optical system 31, a computer control system 40, a vacuum workpiece chamber 29 and a workpiece console 26 placed in the workpiece chamber, and the vacuum workpiece chamber is placed on the anti-vibration table 25. The electron optical system is placed above the vacuum workpiece chamber and works in electron beam scanning mode. The computer control system controls the high-voltage power supply 36, the grid power supply 37, the electron lens power supply 38, the deflection coil control 39 and the workpiece console.

[0049] Among them, the electron optical system is composed of a cathode 35, a grid 34, an electron lens 33, and a deflection coil 30. The cathode emits an electron beam 32, the grid controls the on-off of the electron beam, the electron lens realizes the focusing of the electron beam, and the deflection coil is fixed on the workpiece. The outer...

Embodiment 3

[0058] In this example, the electron beam crystallization device is as Figure 5 As shown, it mainly includes: an electron optical system 47, a computer control system 56, a workpiece chamber 44 and a workpiece console 42 placed in the workpiece chamber. The electron optical system is placed above the workpiece chamber and is vacuum-sealed with the workpiece chamber. The electron optical system works in electron beam scanning mode. The computer control system controls the high voltage power supply 52 , the grid power supply 53 , the electron lens power supply 54 , the deflection coil control 55 and the workpiece console 42 .

[0059] Among them, the electron optical system is composed of a cathode 51, a grid 50, an electron lens 49, and a deflection coil 45. The cathode emits an electron beam 48, the grid controls the on-off of the electron beam, the electron lens realizes the focusing of the electron beam, and the deflection coil is fixed on the workpiece. The outer or inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com