Sulfonation process for producing dye dispersant and concrete water reducing agent

A technology of concrete water reducer and dye dispersant, applied in the direction of organic chemistry, organic chemical methods, chemical instruments and methods, etc., can solve problems such as loss and environmental impact, and achieve the effect of improving production efficiency and shortening production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

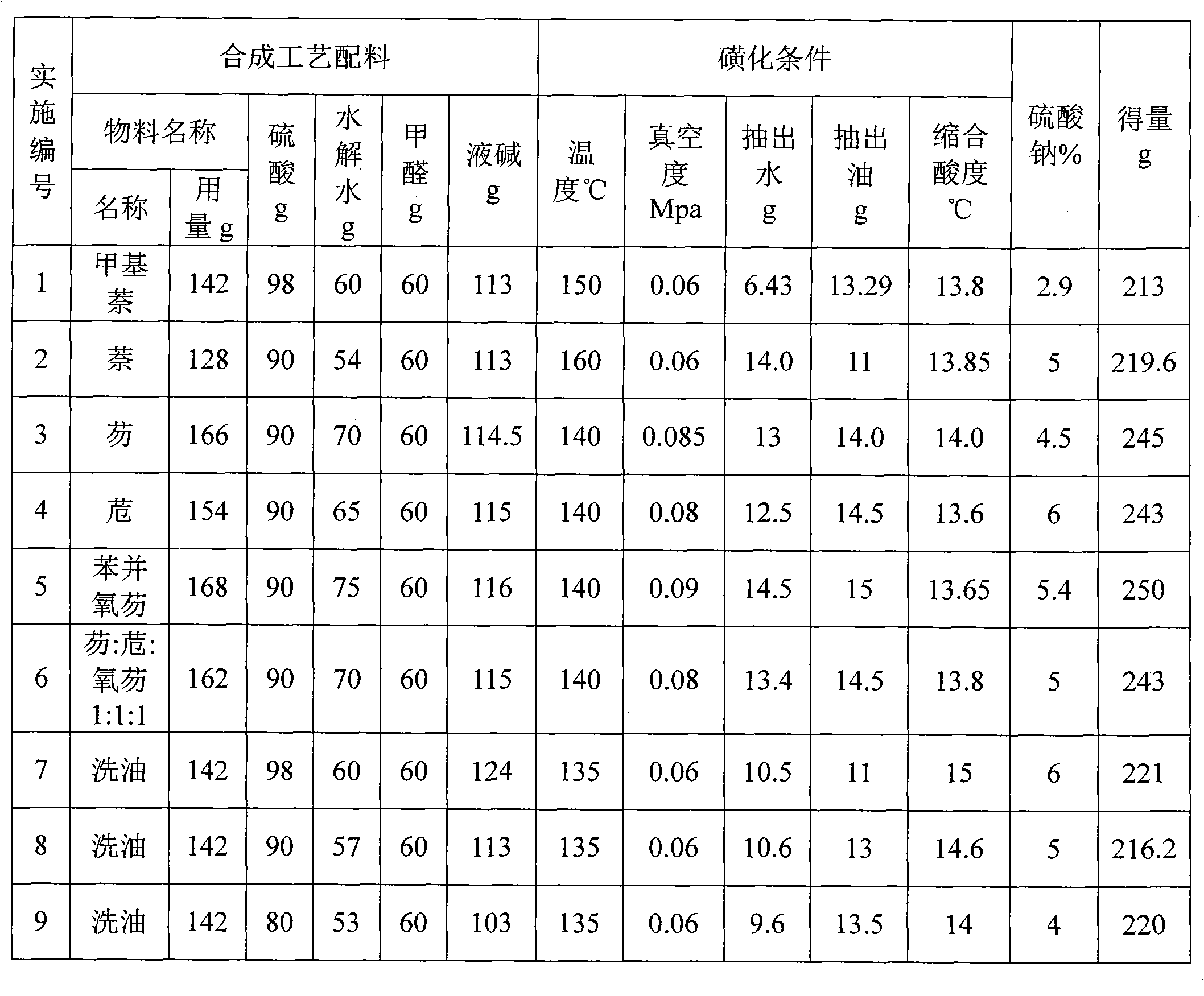

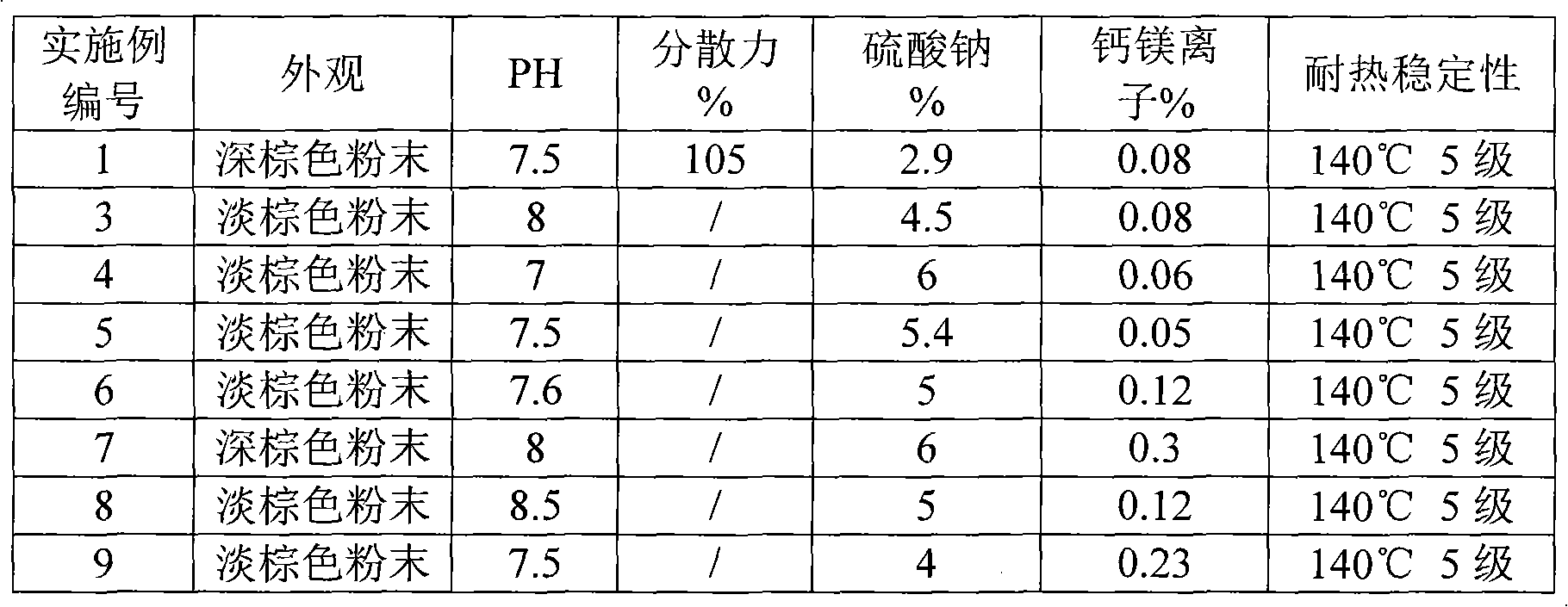

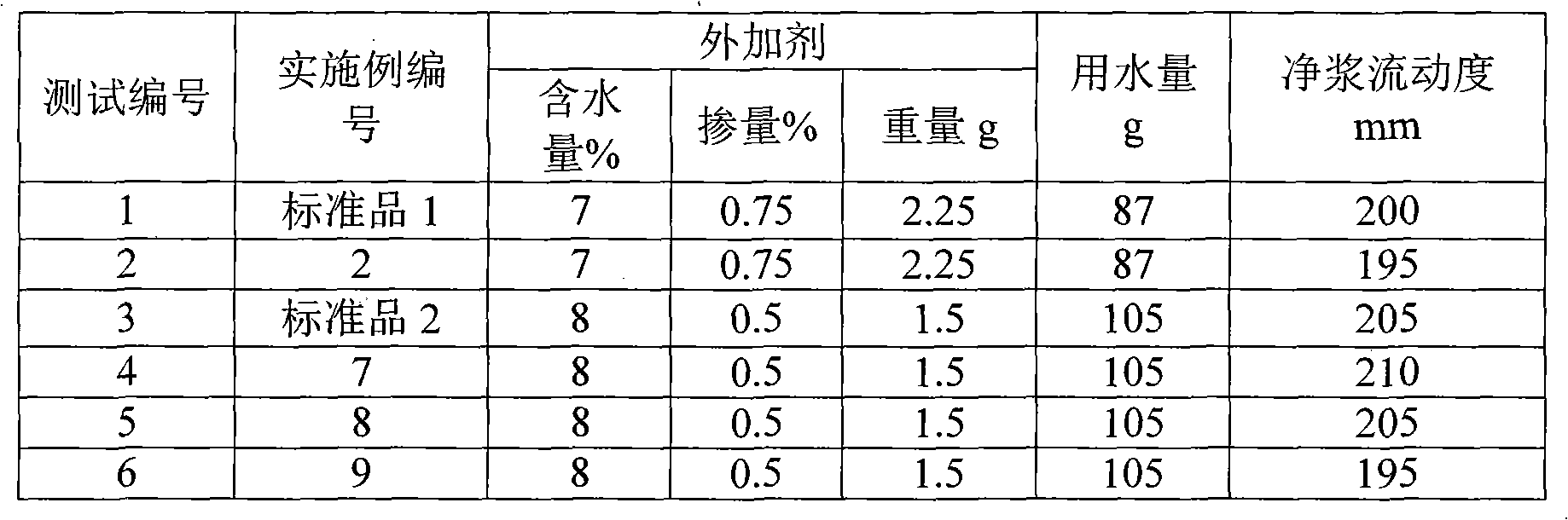

Examples

Embodiment 1

[0013] Take by weighing methylnaphthalene 142 grams and put into the 500 milliliters of four-neck flasks that agitator, thermometer, condenser tube are housed, start stirring, heating furnace heating. When temperature rises to 110 ℃, start to drop 98 grams of 98% sulfuric acid. After the dropwise addition was completed, when the temperature was raised to 150°C and the vacuum was started to reach 0.06Mpa, and the temperature was kept, water and oil flowed out. After 3 hours of incubation, the reaction ended. Stop the vacuum, cool to 120°C, add water and hydrolyze to measure the acidity. Collect and separate the effluent water and oil layers. The next sulfonation of the oil layer can be reused. When the sulfonated material was cooled to 80°C, 60 grams of 37% formaldehyde was added dropwise, and the temperature was controlled not to exceed 90°C. After dropping, heat up to 100-105°C for condensation reaction. Leave on for 6 hours to finish. Add 32% liquid caustic soda to neu...

Embodiment 2

[0015] Take by weighing 128 grams of naphthalene and put into the 500 milliliter four-neck flask that stirrer, thermometer, condenser tube are housed, start stirring, heating furnace heating. When temperature rises to 110 ℃, start to drop 90 grams of 98% sulfuric acid. After the dropwise addition was completed, when the temperature was raised to 160°C and the vacuum was started to reach 0.06Mpa, and the temperature was kept, water and oil flowed out. After 3 hours of incubation, the reaction ended. Stop the vacuum, cool to 120°C, add water and hydrolyze to measure the acidity. Collect and separate the effluent water and oil layers. The next sulfonation of the oil layer can be reused. When the sulfonated material was cooled to 80°C, 60 grams of 37% formaldehyde was added dropwise, and the temperature was controlled not to exceed 90°C. After dropping, heat up to 100-105°C for condensation reaction. Leave on for 6 hours to finish. Add 32% liquid caustic soda to neutralize. ...

Embodiment 3

[0017] Weigh 166 grams of fluorene and put it into a 500-milliliter four-neck flask equipped with a stirrer, a thermometer, and a condenser tube, start stirring, and heat in a heating furnace. When temperature rises to 110 ℃, start to drop 90 grams of 98% sulfuric acid. After the dropwise addition was completed, when the temperature was raised to 140°C and the vacuum was started to reach 0.085Mpa, and kept warm, water and oil flowed out. After 3 hours of incubation, the reaction ended. Stop the vacuum, cool to 120°C, add water and hydrolyze to measure the acidity. Collect and separate the effluent water and oil layers. The next sulfonation of the oil layer can be reused. When the sulfonated material was cooled to 80°C, 60 grams of 37% formaldehyde was added dropwise, and the temperature was controlled not to exceed 90°C. After dropping, heat up to 100-105°C for condensation reaction. Leave on for 6 hours to finish. Add 32% liquid caustic soda to neutralize. The neutrali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com