Preparation method for fast separating flavonoid glycosides from oil-tea-cakes with medium pressure column

A technology of flavonoid glycosides and oil tea cakes in meal, which is applied in the field of preparation of flavonoid glycosides, and can solve the problems of slow separation process and low yield of silica gel column chromatography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step one, degreasing:

[0031] Camellia oleifera seeds were shelled, seeds were crushed, and petroleum ether was used to degrease, the ratio of tea seeds to petroleum ether was 1:30g / mL, the temperature was 60°C, extraction was carried out for 2 hours, extracted 3 times, and the filter residue was obtained after filtration to obtain defatted camellia oleifera seed meal;

[0032] The second step, extract:

[0033] Add 1 g of raw material to 20 mL of 70% concentration alcohol-water solution to extract 3 times, extraction temperature is 80°C, extraction time is 2 hours, after extraction, filter, combine filtrates, concentrate in vacuum to obtain crude extract of flavonoid glycosides of camellia oleifera;

[0034] The third step, extraction:

[0035] The extract obtained from the extract is extracted 4 times with n-butanol, and the aqueous layer is concentrated to obtain a phase extract;

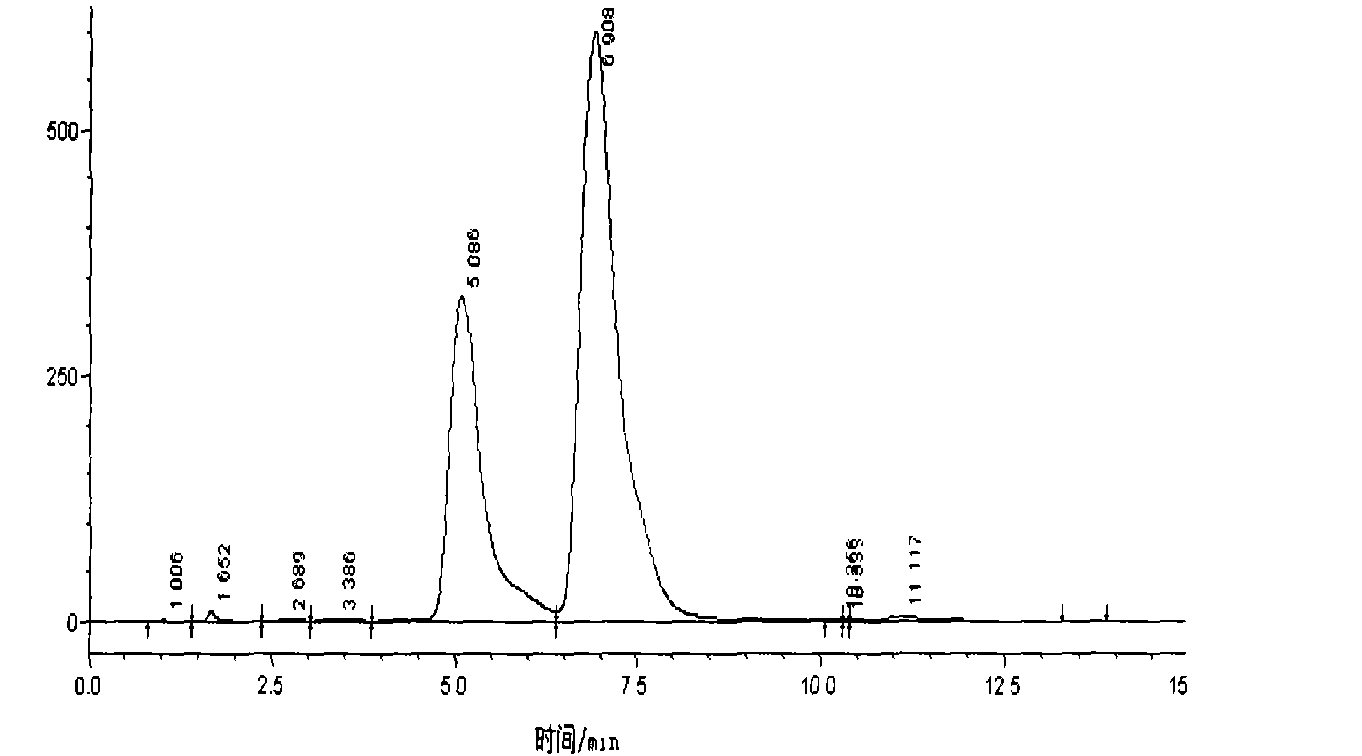

[0036] The fourth step, medium pressure column purification:

[0037] The crude ex...

Embodiment 2

[0044] Step one, degreasing:

[0045] Camellia oleifera seeds were shelled, seeds were crushed, and petroleum ether was used to degrease, the ratio of tea seeds to petroleum ether was 1:30g / mL, the temperature was 60°C, extraction was carried out for 2 hours, extracted 3 times, and the filter residue was obtained after filtration to obtain defatted camellia oleifera seed meal;

[0046] The second step, extract:

[0047] Add 1 g of raw material to 20 mL of 50% methanol solution for extraction of Camellia oleifera seed meal for 3 times, extraction temperature is 80°C, extraction time is 2 hours, after extraction, filter, combine the filtrates, and vacuum concentrate to obtain the crude extract of flavonoid glycosides of camellia oleifera meal;

[0048] The third step, extraction:

[0049] The extract obtained from the extract is extracted 4 times with acetone, and the aqueous layer is concentrated to obtain a crude extract;

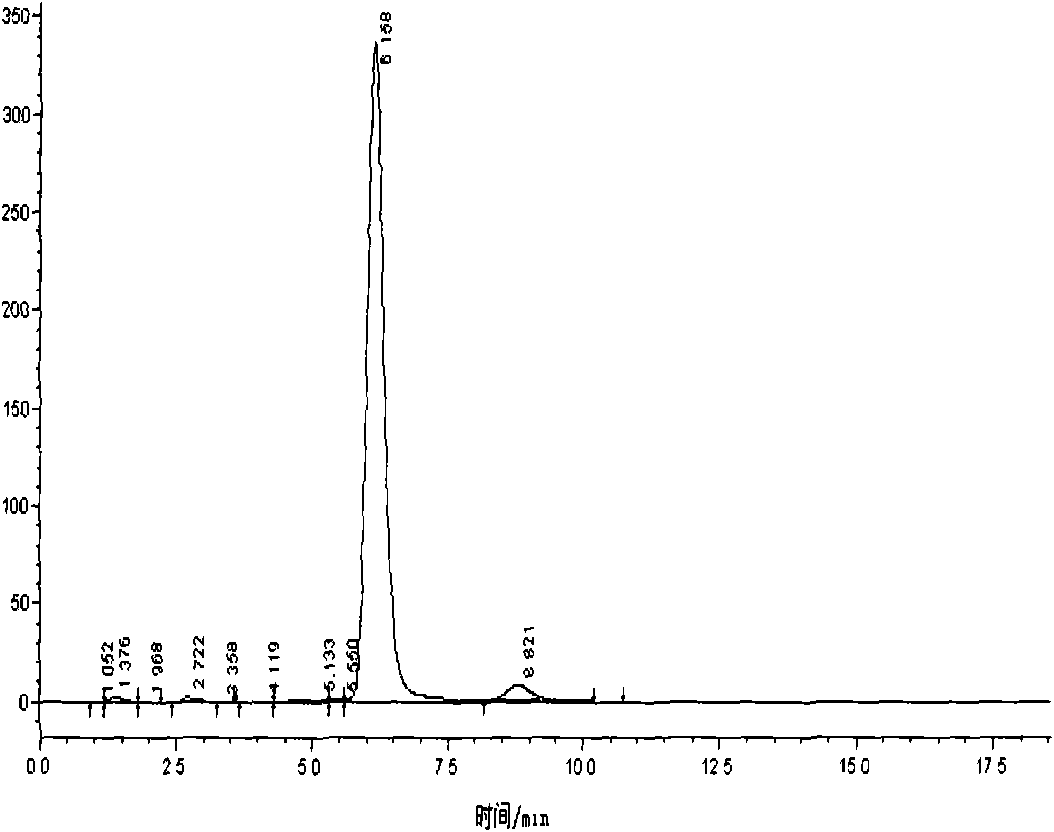

[0050] The fourth step, medium pressure column puri...

Embodiment 3

[0055] Step one, degreasing:

[0056] Camellia oleifera seeds were shelled, seeds were crushed, and petroleum ether was used to degrease, the ratio of tea seeds to petroleum ether was 1:30g / mL, the temperature was 60°C, extraction was carried out for 2 hours, extracted 3 times, and the filter residue was obtained after filtration to obtain defatted camellia oleifera seed meal;

[0057] The second step, extract:

[0058] Add 1 g of raw material to 20 mL of 70% ethanol solution to extract 3 times of Camellia oleifera seed meal, extraction temperature is 80°C, extraction time is 2 hours, after extraction, filter, combine filtrate, vacuum concentrate to obtain crude extract of flavonoid glycosides of camellia oleifera meal;

[0059] The third step, extraction:

[0060] The extract obtained from the extract was extracted 4 times with n-butanol, and the aqueous layer was concentrated to obtain a crude extract;

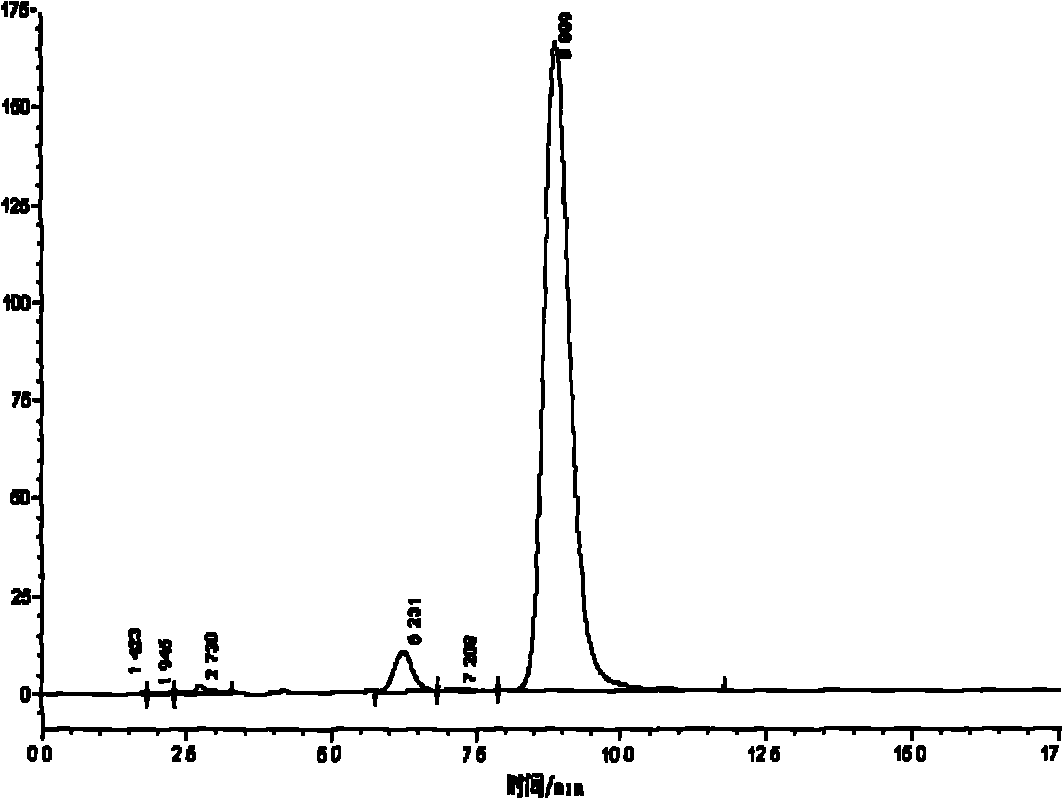

[0061] The fourth step, medium pressure column purification:

[0062...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com