Method for preparing heavy distillate hydrotreating catalyst

An acid treatment and catalytic material technology, applied in molecular sieve catalysts, physical/chemical process catalysts, catalyst carriers, etc., can solve the problems of poor pore connectivity, poor carrier mixing uniformity, and small mesoporous ratio, and improve the dispersibility. The effect of catalyst activity, good connectivity and openness, and large pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

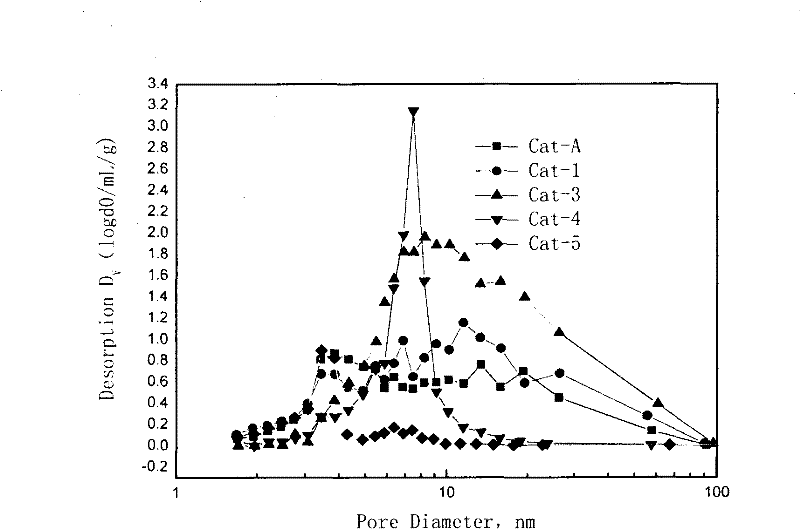

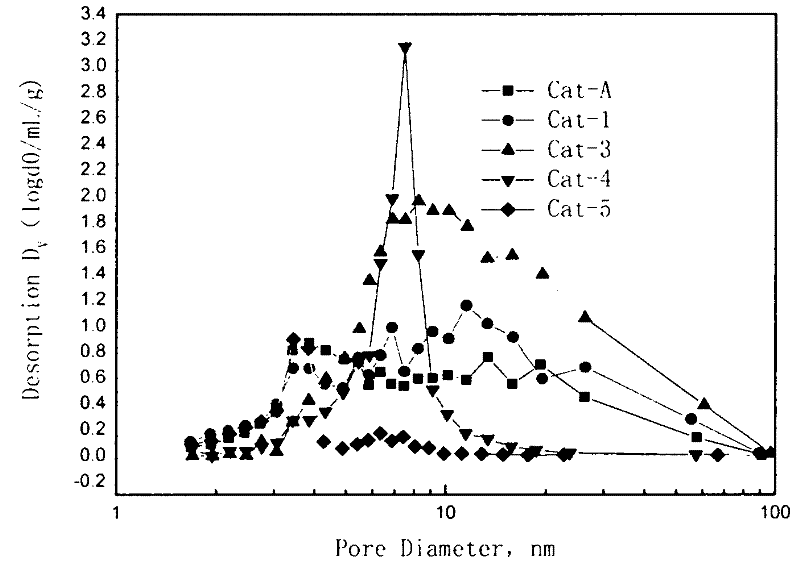

Image

Examples

preparation example Construction

[0038] The preparation method of the composite catalytic material provided by the invention and the preparation method of the heavy distillate oil hydrotreating catalyst can be carried out according to the following specific steps:

[0039] (1), the Y-type molecular sieve is converted into a hydrogen-type Y-type molecular sieve by an ion exchange method, and roasted at 500° C. for 3-6 hours in an air atmosphere;

[0040] (2) Pretreatment (acid treatment) of hydrogen type Y molecular sieve by acid dealumination, the acid used is citric acid, tartaric acid or hydrochloric acid, etc., the specific treatment is as follows: the utilization concentration is 0.5-2.0mol L -1 Soak the molecular sieve with acid (the volume ratio of the two is 1:1-5:1), react at room temperature for 1-5 hours, then dry the filtered and washed molecular sieve at 120°C for 2 hours, and then dry it at 400-600 Roasting in an air atmosphere at ℃ for 2-5 hours to obtain acid-treated Y molecular sieves;

[004...

Embodiment 1

[0049] Example 1 Preparation of Y / TiO by in situ growth 2 -SiO 2 Composite support and catalyst

[0050] Weigh 34.0g of tetrabutyl titanate and 20.8g of tetrabutyl titanate and 20.8g of ethyl orthosilicate, dissolve them in ethanol respectively, and then mix them uniformly to obtain solution A; mix 19mL of deionized water, 41.2mL of acetic acid and 40mL of absolute ethanol to obtain solution B; Under strong stirring, drop solution B into A for reaction. After the dropwise addition and react for 20 minutes, add 3 g of HY molecular sieves and react for 10 minutes to obtain a sol;

[0051] Aging the sol for 24-48h under natural conditions to obtain a gel;

[0052] Use supercritical carbon dioxide fluid to dry the gel to obtain a white powder. The drying conditions are: temperature 40°C, pressure 8.0-12.0MPa, drying time 1-2 hours;

[0053] Roast the white powder in a muffle furnace at 500-600°C for 3 hours to obtain Y / TiO 2 -SiO 2 Composite carrier (composite catalytic mater...

Embodiment 2

[0056] Example 2 Preparation of CY / TiO by in-situ growth 2 -SiO 2 Composite support and catalyst

[0057] The HY molecular sieve in Example 1 was replaced with CY molecular sieve after acid pretreatment, and the preparation steps of CY molecular sieve were as follows: adding HY molecular sieve to a concentration of 0.5mol L -1 NH 4 NO 3 In the aqueous solution, the mass ratio of solid to liquid is 1:10, stir and heat to 40°C, add dropwise citric acid solution, after the dropwise addition, continue to stir for 30min, then filter and wash the slurry until neutral, fully dry and place in a muffle furnace Calcined at 500°C for 3 hours to obtain nCY molecular sieve, wherein, n is the ratio of the mass of HY molecular sieve to the mass of citric acid used, and the range of n is 5-60, and the value of n in this embodiment is 16.

[0058] The preparation steps and conditions of the composite carrier and catalyst are the same as in Example 1, and the obtained catalyst is designated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com