Gradation Combination Method and Application of Hydrodesulfurization Catalyst and Hydrofining Catalyst

A hydrodesulfurization and hydrofining technology, which is applied in the gradation combination of hydrofining catalysts and in the field of hydrodesulfurization catalysts, can solve the problems of affecting catalyst activity and life, no solution proposed, insufficient catalytic activity, etc., and achieve effective It is beneficial to desulfurization reaction, reduces catalyst cost and improves catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] According to some embodiments of the present application, the preparation method of the mesoporous alumina and mesoporous molecular sieve composite material includes:

[0063] Using P123 as a template agent, mix it with mesoporous molecular sieve evenly to prepare the first solution;

[0064] adding an aluminum source and an inorganic acid to the first solution to prepare a second solution;

[0065] The second solution is left to stand for a specified time, dried to remove the solvent, and calcined to obtain a composite material of mesoporous alumina and mesoporous molecular sieve.

[0066] According to some preferred embodiments of the present application, the aluminum source is aluminum isopropoxide; the inorganic acid is nitric acid; the specified time is 2-6 hours; and the calcination temperature is 500-580°C.

[0067] According to some embodiments of the present application, the mesoporous molecular sieve is one or more of Beta-FDU-12, Beta-SBA-16 and Beta-KIT-6 c...

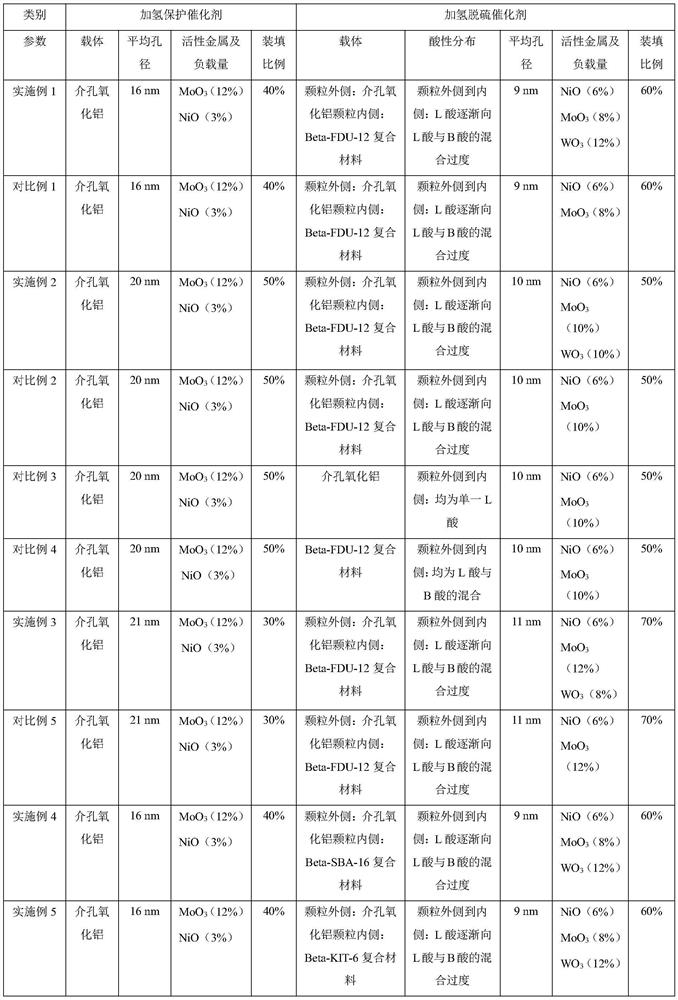

Embodiment 1

[0080] This example presents a hydrodesulfurization catalyst.

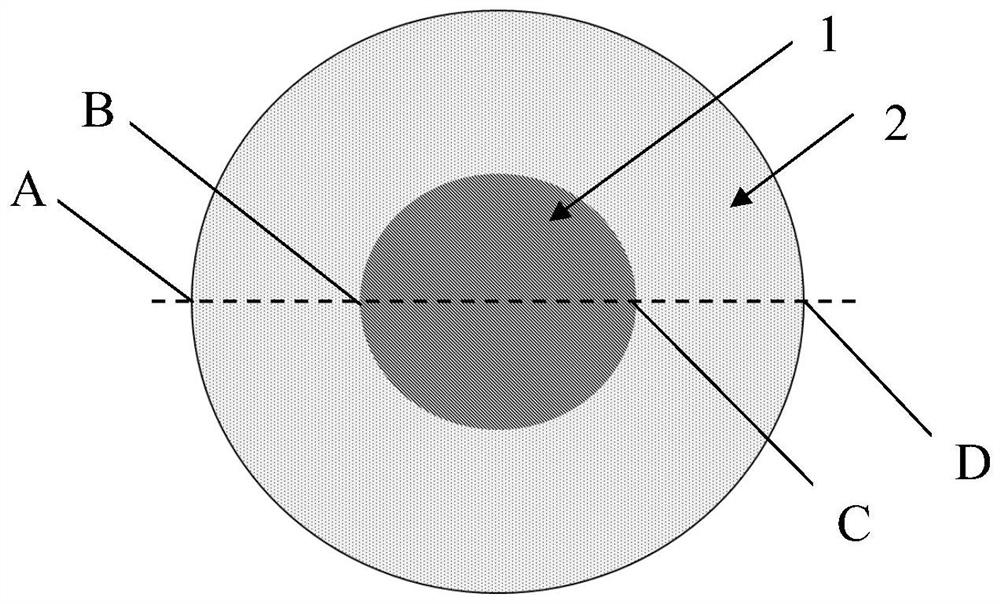

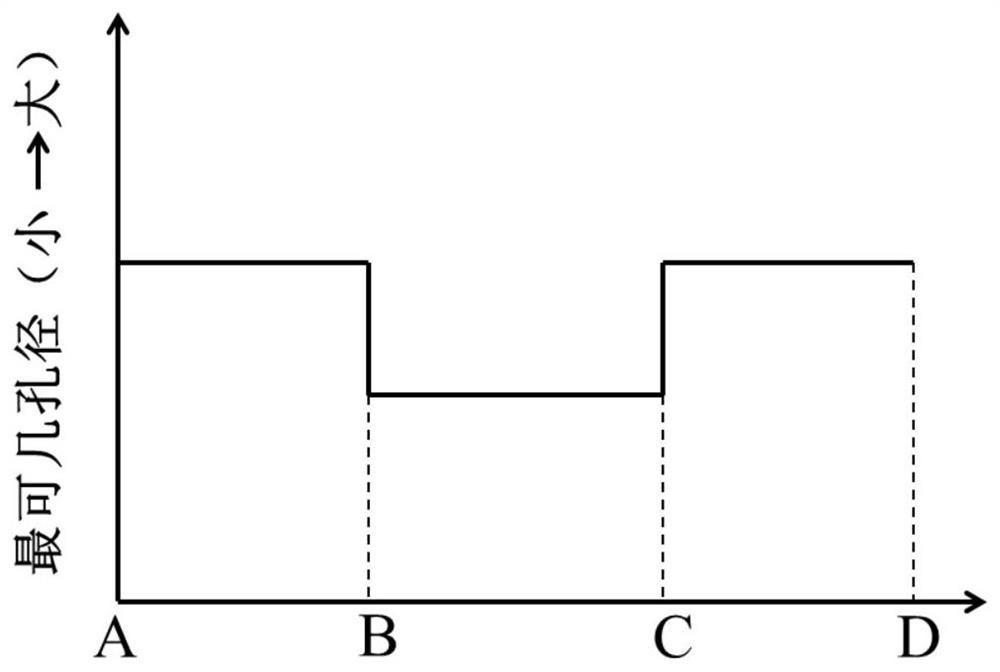

[0081] The pore size of the hydrodesulfurization catalyst particles gradually decreases from the outer side to the inner side, and the acidity of the catalyst gradually transitions from L acid to L acid and B acid.

[0082] The carrier of the hydrodesulfurization catalyst particles is a composite material of mesoporous alumina and mesoporous molecular sieve, wherein the mesoporous alumina is located on the outside of the composite material, and the mesoporous molecular sieve is located on the inside of the composite material. The average pore diameter of the catalyst is 9nm, and the active metal loads are respectively NiO (6% by mass fraction, the following percentage examples are all mass fractions), MoO 3 (8%) and WO 3 (12%).

[0083] This example also provides a method for gradation combination of hydrorefining catalysts.

[0084] The loading sequence of the catalysts in the reactor along the flow direction ...

Embodiment 2

[0111] This example provides a method for gradation combination of hydrofining catalysts.

[0112] The filling sequence in the reactor along the flow direction of the reactant materials is the mesoporous alumina-based hydrogenation protection catalyst and the mesoporous alumina and mesoporous molecular sieve composite material-based hydrodesulfurization catalyst.

[0113] The pore size of hydrodesulfurization catalyst particles gradually decreases from the outside to the inside, and the acidity of the catalyst gradually transitions from L acid to L acid and B acid.

[0114] Specifically, the hydrogenation protection catalyst adopts mesoporous alumina carrier, the most probable pore diameter is 20nm, and the active metal loading is MoO 3 (12%) and NiO (3%), the loading accounts for 50% of the total catalyst mass.

[0115] The particle carrier of hydrodesulfurization catalyst is mesoporous alumina and mesoporous molecular sieve composite material with mesoporous molecular sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com