Manufacturing method of dual-template of three-dimensionally ordered macroporous lanthanum manganate with mesoporous wall of hole

A three-dimensional ordered, dual-template technology, applied in the direction of manganate/permanganate, etc., to achieve the effect of cheap raw materials, simple preparation process, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

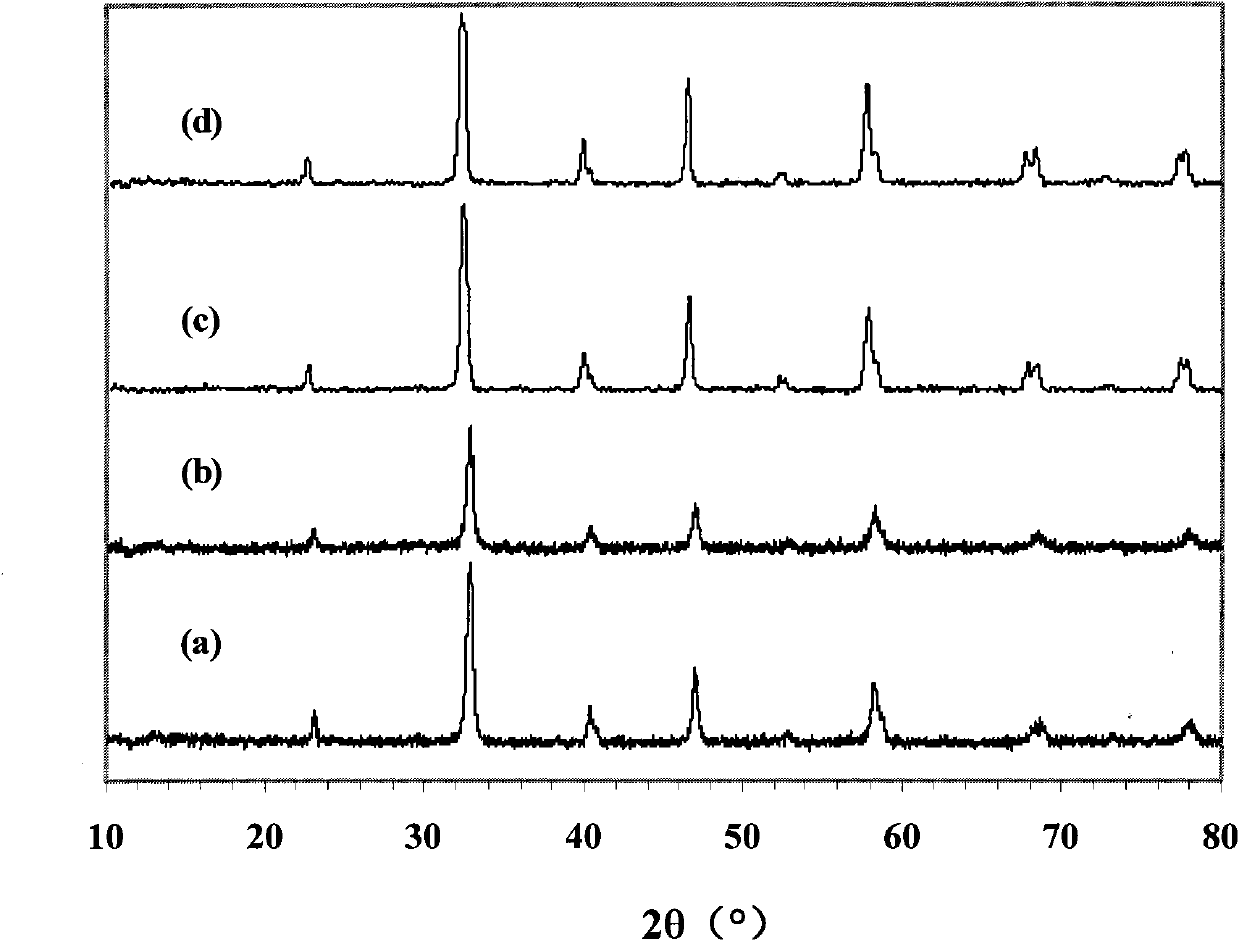

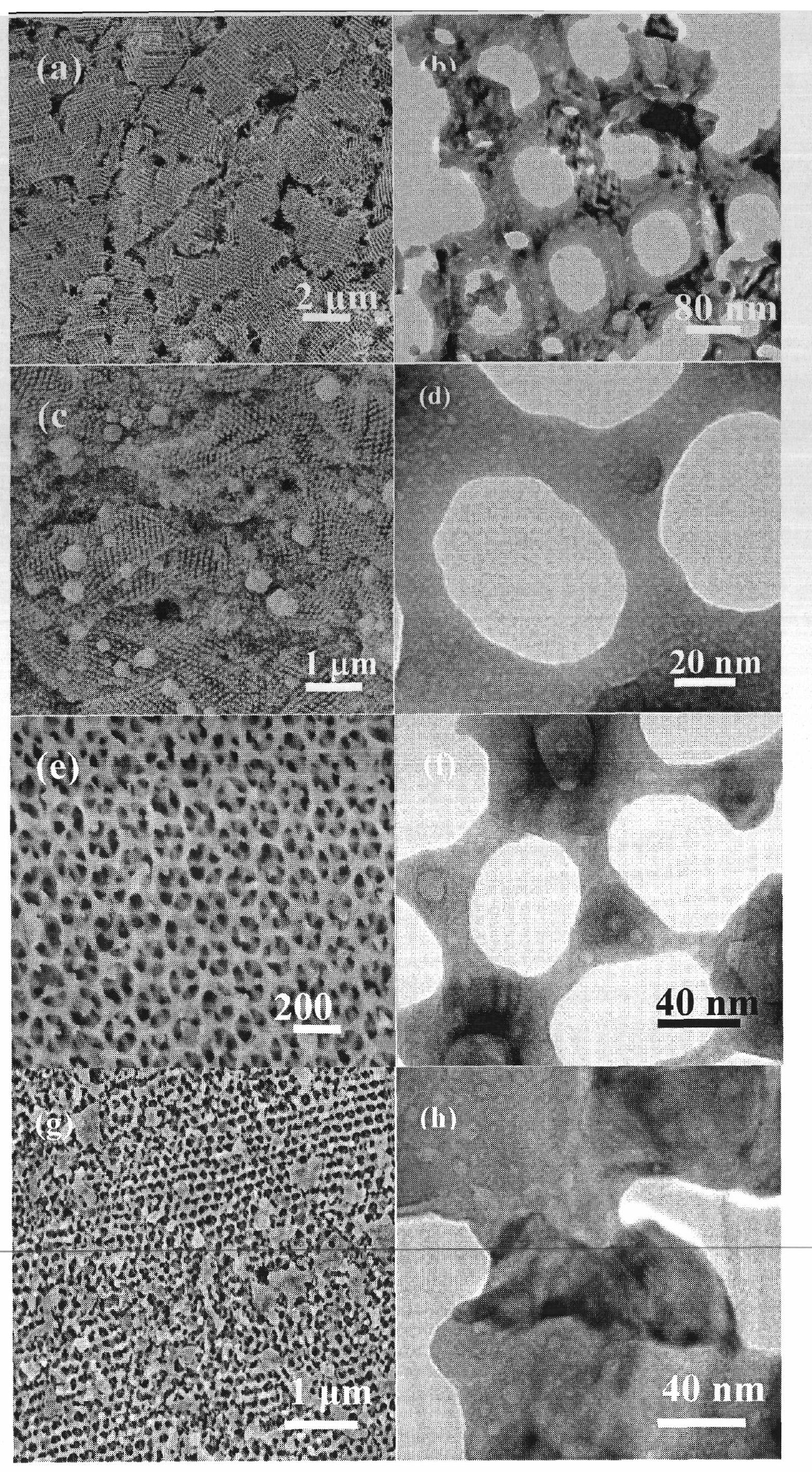

Embodiment 1

[0017] Embodiment 1: Weigh 12.99g La (NO 3 ) 3 ·6H 2 O and 8.32 ml of 50% Mn (NO 3 ) 2The aqueous solution was placed in a 50 mL beaker, 3 mL of polyethylene glycol 400 was added, and after magnetic stirring for 4 h, a homogeneous solution was formed, and this solution was the precursor solution. Weigh 1.0 g of L-lysine with 2 mol / L nitric acid solution to adjust the pH of the solution to 6. After magnetic stirring for 1 h, a homogeneous solution was formed. This solution was added to the precursor salt solution, followed by 9 mL of methanol. The above mixture was poured into a 50 mL beaker containing 1.0 g of polymethyl methacrylate (PMMA) hard template. In order to maintain the original orderly arrangement of PMMA, no stirring was performed during the pouring of the mixed solution. The mixed solution was immersed in PMMA for about 5 hours, and the samples obtained by suction filtration were dried at room temperature for 24 hours, and then the samples were loaded into a ...

Embodiment 2

[0018] Embodiment 2: Weigh 12.99g La (NO 3 ) 3 ·6H 2 O and 8.32 ml of 50% Mn (NO 3 ) 2 The aqueous solution was placed in a 50 mL beaker, 3 mL of polyethylene glycol 400 was added, and after magnetic stirring for 4 h, a homogeneous solution was formed, and this solution was the precursor solution. Weigh 4.0 g of L-lysine and adjust the pH to 6 with 2 mol / L nitric acid solution. After magnetic stirring for 1 h, a homogeneous solution is formed. This solution is added to the precursor salt solution, followed by 2 mL of methanol. The above mixture was poured into a 50 mL beaker containing 1.0 g of PMMA hard template. In order to maintain the original orderly arrangement of PMMA, no stirring was performed during the pouring of the mixed solution. The mixed solution was immersed in PMMA for about 5 hours, and the samples obtained by suction filtration were dried at room temperature for 24 hours, and then the samples were loaded into a magnetic boat and placed in a tube furnace...

Embodiment 3

[0019] Embodiment 3: Weigh 12.99g La (NO 3 ) 3 ·6H 2 O and 8.32 ml of 50% Mn (NO 3 ) 2 The aqueous solution was placed in a 50 mL beaker, 3 mL of polyethylene glycol 400 was added, and after magnetic stirring for 4 h, a homogeneous solution was formed, and this solution was the precursor solution. Weigh 1.0 g of triblock copolymer P123 into a 50 mL beaker, add 10 mL of anhydrous methanol, magnetically stir for 1 h to form a homogeneous solution, add this solution to the precursor salt solution, and then add 4 mL of methanol. The above mixture was poured into a 50 mL beaker containing 1.0 g of PMMA hard template. In order to maintain the original orderly arrangement of PMMA, no stirring was performed during the pouring of the mixed solution. The mixed solution was immersed in PMMA for about 5 hours, and the samples obtained by suction filtration were dried at room temperature for 24 hours, and then the samples were loaded into a magnetic boat and placed in a tube furnace. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com