Diffractive micro-optical element-based intense laser die-free forming method and device

A moldless forming and micro-optical technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large light energy loss and achieve the effects of small light energy loss, improved mechanical properties, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

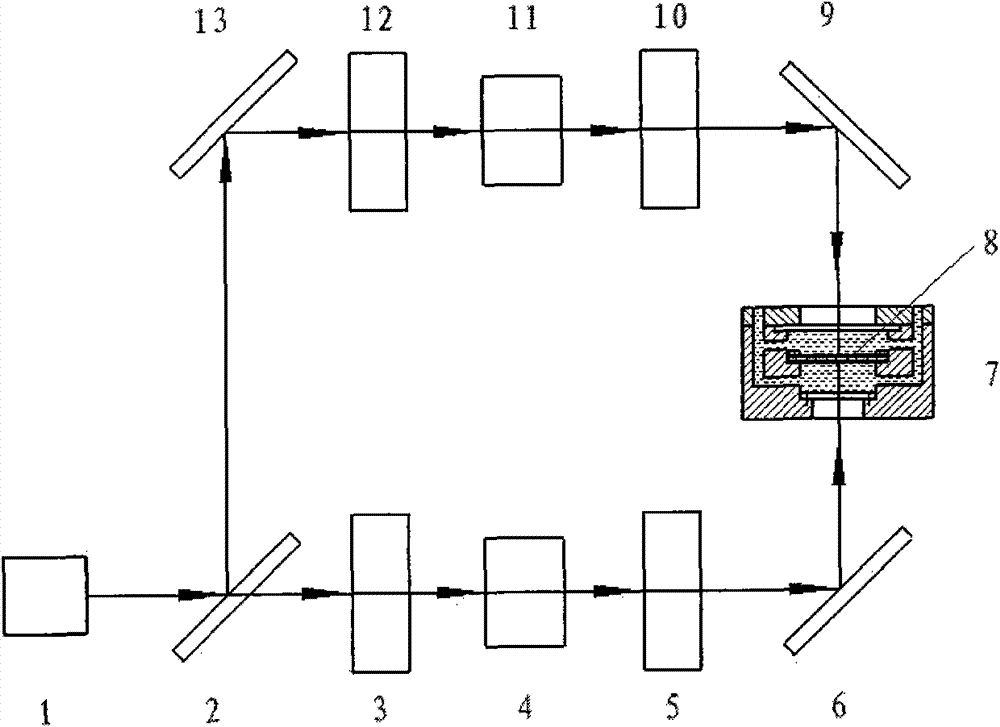

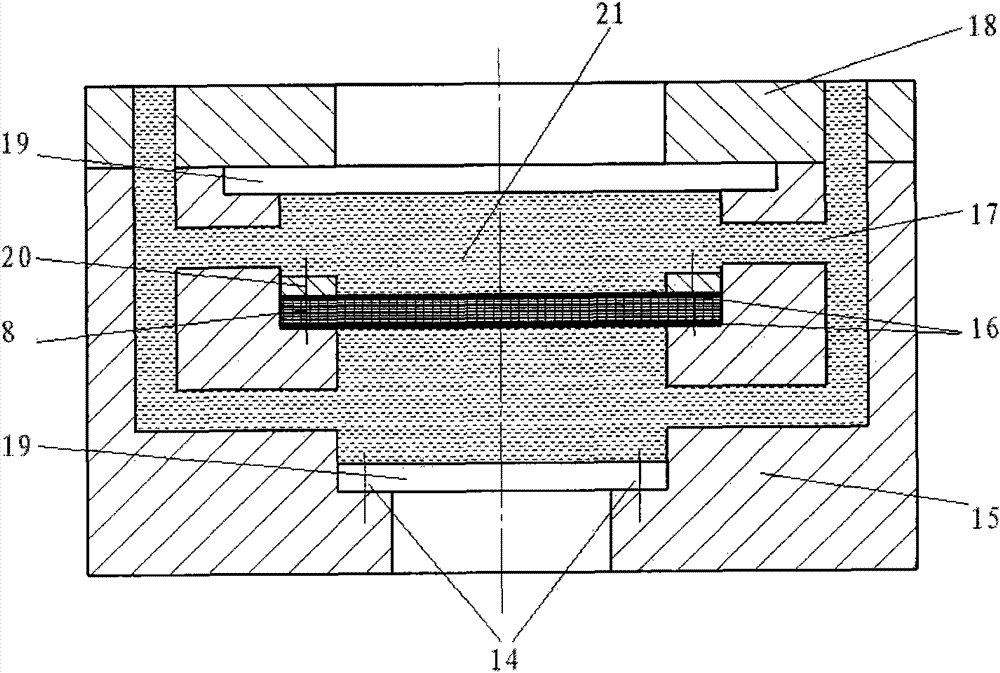

[0021] A laser strong modeless forming device based on diffractive micro-optical elements proposed by the present invention such as figure 1 shown. It consists of laser, beam expander system, modulation shaping system, focusing system and clamping device.

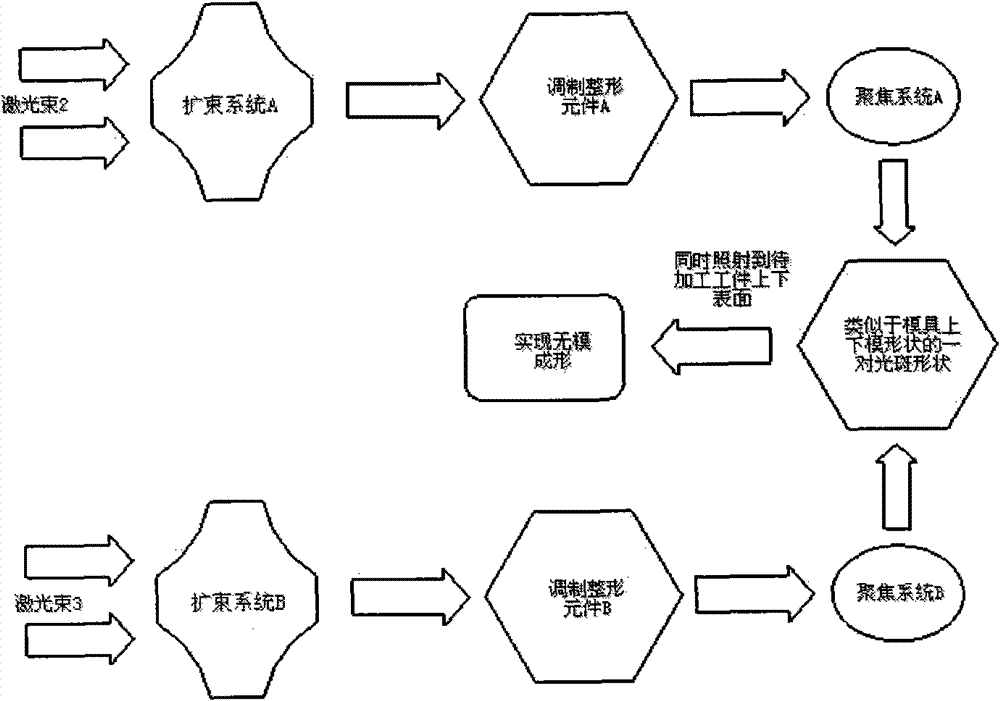

[0022] refer to figure 1 , figure 2 , Figure 4 The implementation process is as follows:

[0023] (1) Fabricate a pair of diffractive micro-optical elements (DOE) that meet the expected requirements. According to the predicted graph and the wavelength of the laser beam, use an appropriate algorithm, such as: Gerchberg-Saxton (GS) algorithm or Yang-Gu (YG) algorithm, hill climbing-simulated annealing hybrid optimization algorithm to design diffractive optical elements (DOE). Reactive ion etching (RIE), UV photolithography (UV Photolithography) technology or laser beam direct writing technology is used to etch on the surface of the substrate material transparent to the laser beam to produce a multi-step micro-relief s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com