Manufacture system of anti-reflection structure on surface of solar cell and manufacture method thereof

A solar cell and anti-reflection technology, applied in circuits, electrical components, final product manufacturing, etc., can solve problems such as template pattern shape fixation, and achieve the effect of reducing reflectivity, improving photoelectric conversion efficiency, and increasing light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

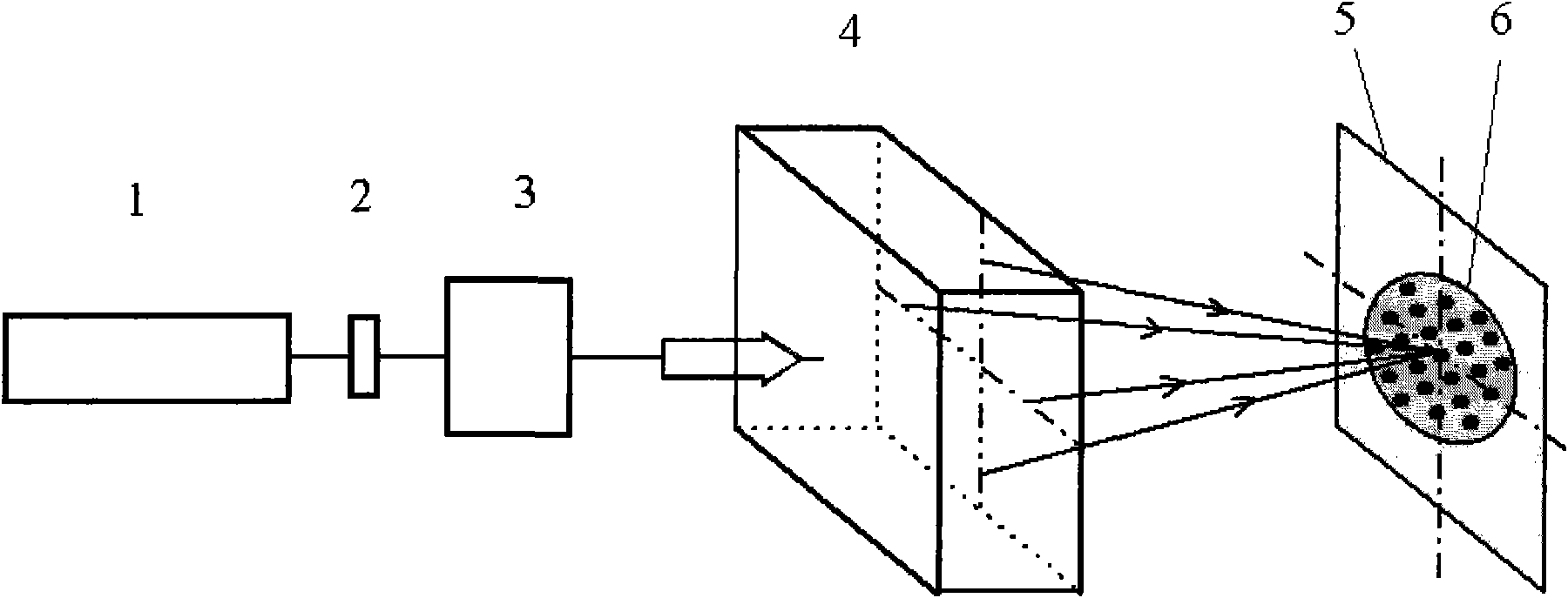

[0035] like figure 1 As shown, the present invention includes: a laser 1, a beam expander 2, a collimation system 3, a beam splitting and refraction system 4, a solar cell substrate or a surface 5 of a solar cell substrate cover plate material. After the laser beam emitted by the laser 1 is expanded by beam 2 and collimated by 3, the beam splitting and refraction system 4 first divides the laser beam into multiple coherent beams, and then controls the respective optical paths of the multiple beams so that they follow the incident angle. In the range of 0° to 90°, the solar cell substrate or the solar cell substrate cover plate material surface 5 is simultaneously irradiated, and the multi-beam interference pattern is used to ablate or expose it to form on its surface such as: Figure 10 Surface anti-reflection structure 6 shown.

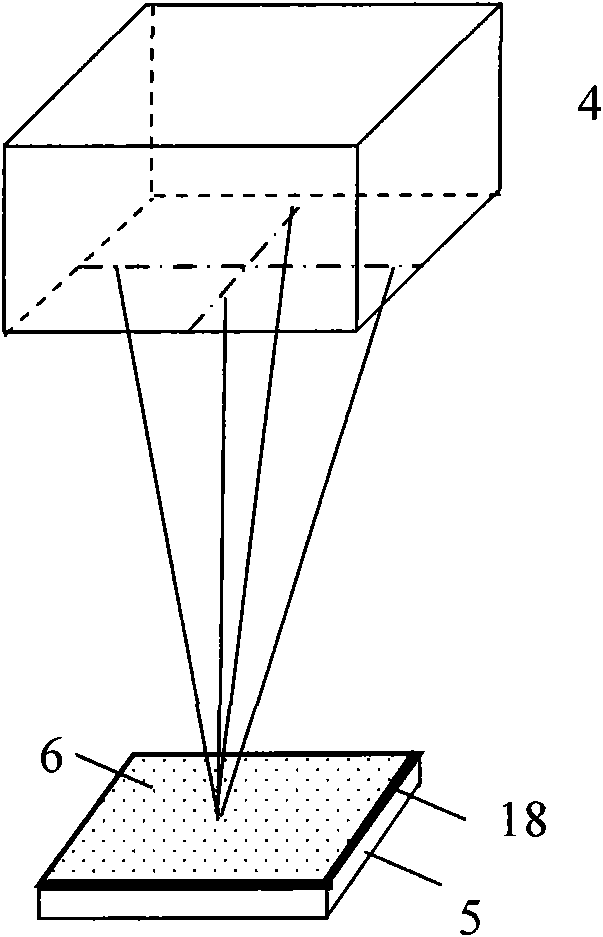

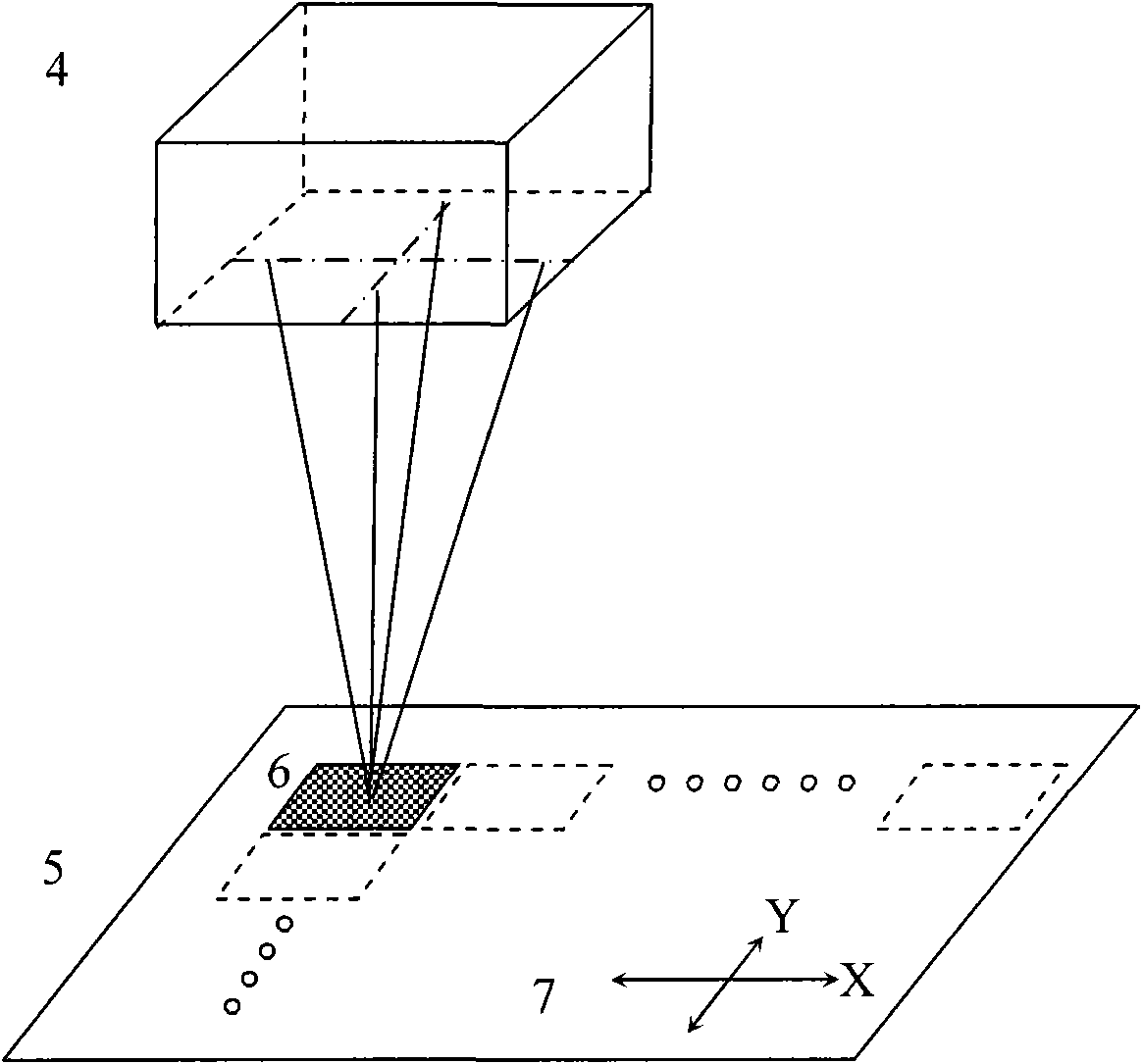

[0036] like figure 2 As shown, it is a schematic diagram of the production system of the solar cell surface anti-reflection structure using the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com