Preparation method of nitrogen-doped attapulgite-supported nano-tio2 visible light catalyst

An attapulgite and visible light technology, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low utilization rate of natural light of photocatalysts, and achieve the effect of improving photocatalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

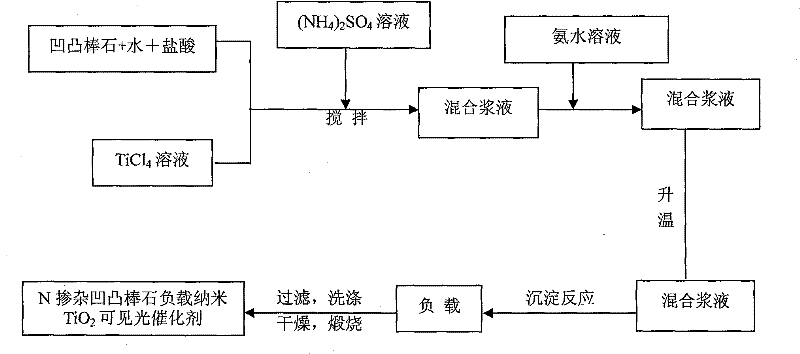

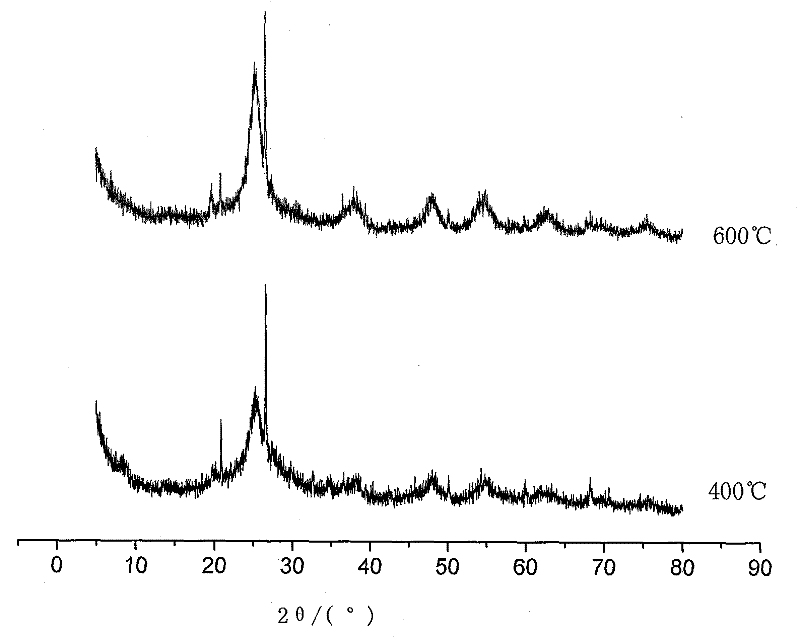

[0027] Take 10g of calcined and purified attapulgite powder, 300ml of deionized and 1ml of concentrated hydrochloric acid and add them into a three-necked flask and stir to make slurry. After stirring evenly, take TiCl 4 Add 20ml (2.71mol / L) of the solution into the flask; measure 20.8ml of ammonium sulfate solution (200g / L) and add it to the reaction system; make 30% concentrated ammonia water and deionized water into an ammonia solution with a volume ratio of 1:1.5 Add it to the slurry, and stop dropping when the pH value of the system is 8.0; react at a temperature of 70°C for 1 hour and then filter and wash with water; the washed filter cake is dried at 105°C and dispersed in a muffle furnace for 600 Calcination at ℃ for 2h.

Embodiment 2

[0029] Take 100g of the purified attapulgite, 3000ml of deionized water and 10ml of concentrated hydrochloric acid and add them into the laboratory reaction kettle to stir and make slurry. After stirring evenly, take TiCl 4 Add 200ml (2.71mol / L) of the solution into the flask; measure 200ml of ammonium sulfate solution (200g / L) and add to the reaction system; make 30% concentrated ammonia water and deionized water into an ammonia solution with a volume ratio of 1:2.0 and add dropwise into the slurry at a rate of 2.2ml / min; stop the dropwise addition when the pH value of the system is 9.0; react at a temperature of 70°C for 1.5h and then filter and wash with water; the washed filter cake is dried at 105°C and beaten After dispersing, heat-preserve and calcinate at 400°C for 2 hours in a muffle furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com