Process for preparing titanium and titanium alloy from titanium hydride powder

A technology for powder preparation and titanium hydride, which is applied in the production and processing of titanium and titanium alloys, and in the field of metal powder preparation and production, can solve the problems of insufficient product density, increase production cost, shorten process flow, etc., and achieve low cost and high yield. , the effect of short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

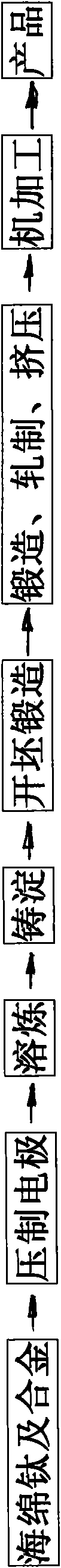

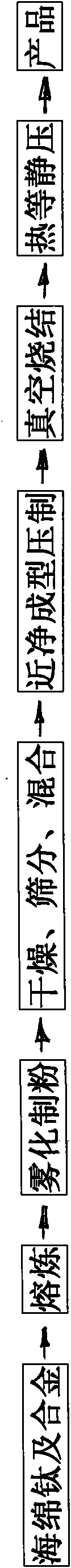

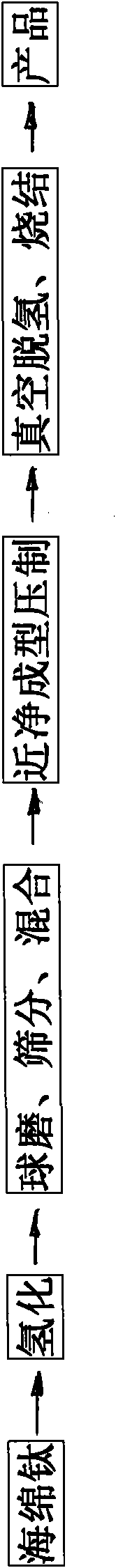

Method used

Image

Examples

Embodiment 1

[0022] Raw materials: According to product requirements, select corresponding grades of titanium sponge in accordance with GB / T2524-2002 (revised edition). Long-term storage of titanium sponge needs to be dried. Drying must be done under vacuum to avoid oxidation. Drying process: temperature 200℃, time 1hour, vacuum degree 1×10 -2 Pa;

[0023] Hydrogenation: Put titanium sponge into hydrogenation furnace for hydrogenation. Vacuum must be drawn before heating and feeding hydrogen, the vacuum degree is 1×10 -2 Pa. Hydrogenation process: temperature 200°C, time 3 hours, hydrogen pressure in the furnace > 1 atmosphere. Hydrogen must be purified by purification facilities;

[0024] Crushing: Put titanium hydride powder into a ball mill for mechanical crushing. Classify after crushing, and the crushing process must be carried out under a protective atmosphere;

[0025] According to product requirements, titanium hydride powder with suitable particle size grade is used for ne...

Embodiment 2

[0029] Raw materials: According to product requirements, select corresponding grades of titanium sponge in accordance with GB / T2524-2002 (revised edition). Long-term storage of titanium sponge needs to be dried. Drying must be done under vacuum to avoid oxidation. Drying process: temperature 210℃, time 1hour, vacuum degree 1×10 -3 Pa;

[0030] Hydrogenation: Put titanium sponge into hydrogenation furnace for hydrogenation. Vacuum must be drawn before heating and feeding hydrogen, the vacuum degree is 1×10 -4 Pa. Hydrogenation process: temperature 700°C, time 3 hours, hydrogen pressure in the furnace > 1 atmosphere. Hydrogen must be purified by purification facilities;

[0031] Crushing: Put titanium hydride powder into a ball mill for mechanical crushing. Classify after crushing, and the crushing process must be carried out under a protective atmosphere;

[0032] According to product requirements, titanium hydride powder with suitable particle size grade is used for ne...

Embodiment 3

[0036] Raw materials: According to product requirements, select corresponding grades of titanium sponge in accordance with GB / T2524-2002 (revised edition). Long-term storage of titanium sponge needs to be dried. Drying must be done under vacuum to avoid oxidation. Drying process: temperature 200℃, time 1hour, vacuum degree 1×10 -2 Pa~1×10 -3 Pa;

[0037] Hydrogenation: Put titanium sponge into hydrogenation furnace for hydrogenation. Vacuum must be drawn before heating and feeding hydrogen, the vacuum degree is 1×10 -2 Pa~1×10 -4 Pa. Hydrogenation process: temperature 200-700 ° C, time 3 hours, hydrogen pressure in the furnace > 1 atmosphere. Hydrogen must be purified by purification facilities;

[0038] Crushing: Put titanium hydride powder into a ball mill for mechanical crushing. Classify after crushing, and the crushing process must be carried out under a protective atmosphere;

[0039] According to product requirements, titanium hydride powder with suitable part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com