Multi-point combustion long-flame gas burner with ultralow nitrogen oxide (NOx) emission

A gas burner, nitrogen oxide technology, applied to ethylene cracking furnace, flat long flame, ultra-low NOx gas burner, large capacity field, can solve the problem of shortened furnace tube life, high NOx emissions, and furnace tube bending deformation and other problems, to achieve the effect of simple maintenance and control, reasonable heat flow distribution and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

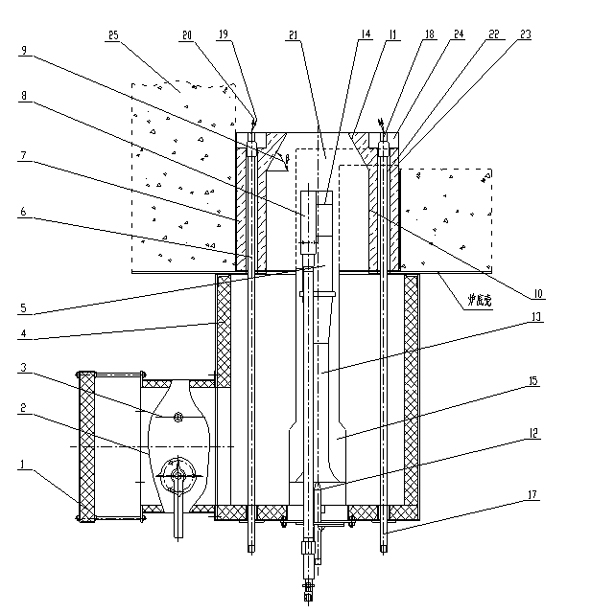

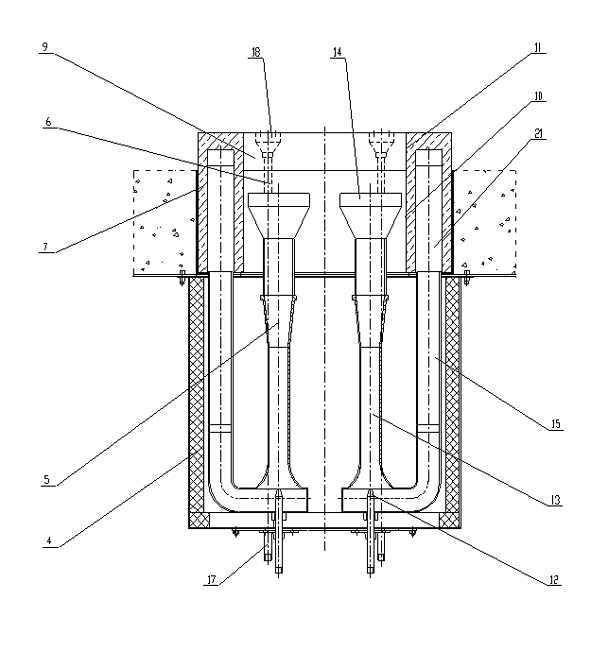

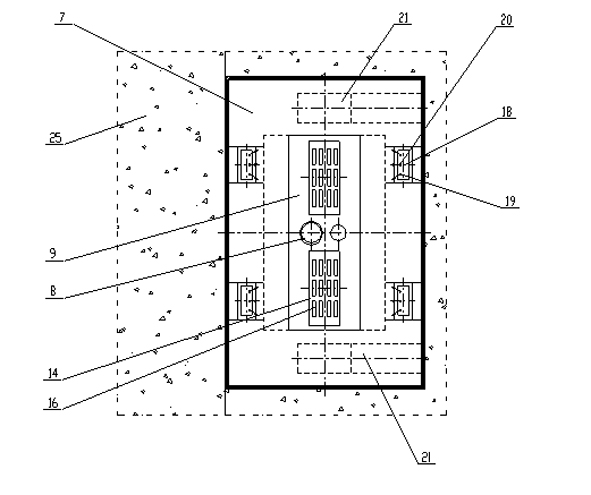

[0031] figure 1 Shown is a kind of gas burner with long flame ultra-low nitrogen oxide emission for multi-point combustion of ethylene cracking furnace applying the present invention, which mainly consists of sound-absorbing cover 1, air duct 2, air regulating baffle 3, wind box 4. Composed of primary burner 5, secondary burner 6, burner brick 7, and permanent lamp 8. It is only one form of the invention and the invention is not limited thereto.

[0032] refer to Figure 1 ~ Figure 4 , the gas burner has 2 primary burners 5 and 4 secondary burners 6 . The primary burner 5 is composed of a primary fuel nozzle 12, an injector 13, a burner 14, and a circulating flue 15, and the burner 14 is provided with 12 elongated flame holes 16. The primary fuel is sprayed into the injector 13 from the primary fuel nozzle 12 in a free-jet manner, forming a low-pressure zone inside the injector 13, so that the flue gas in the furnace passes through the burner brick 7 The upper flue 21 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com