Cathode material and battery containing same

A technology of negative electrode materials and active materials, which is applied in the field of negative electrode materials and batteries containing the negative electrode materials, which can solve the problems of affecting the safety performance of the battery, the battery is prone to swelling, and cannot be used normally, and achieves long cycle performance and good rate discharge performance , Improve the effect of safety performance and quality safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

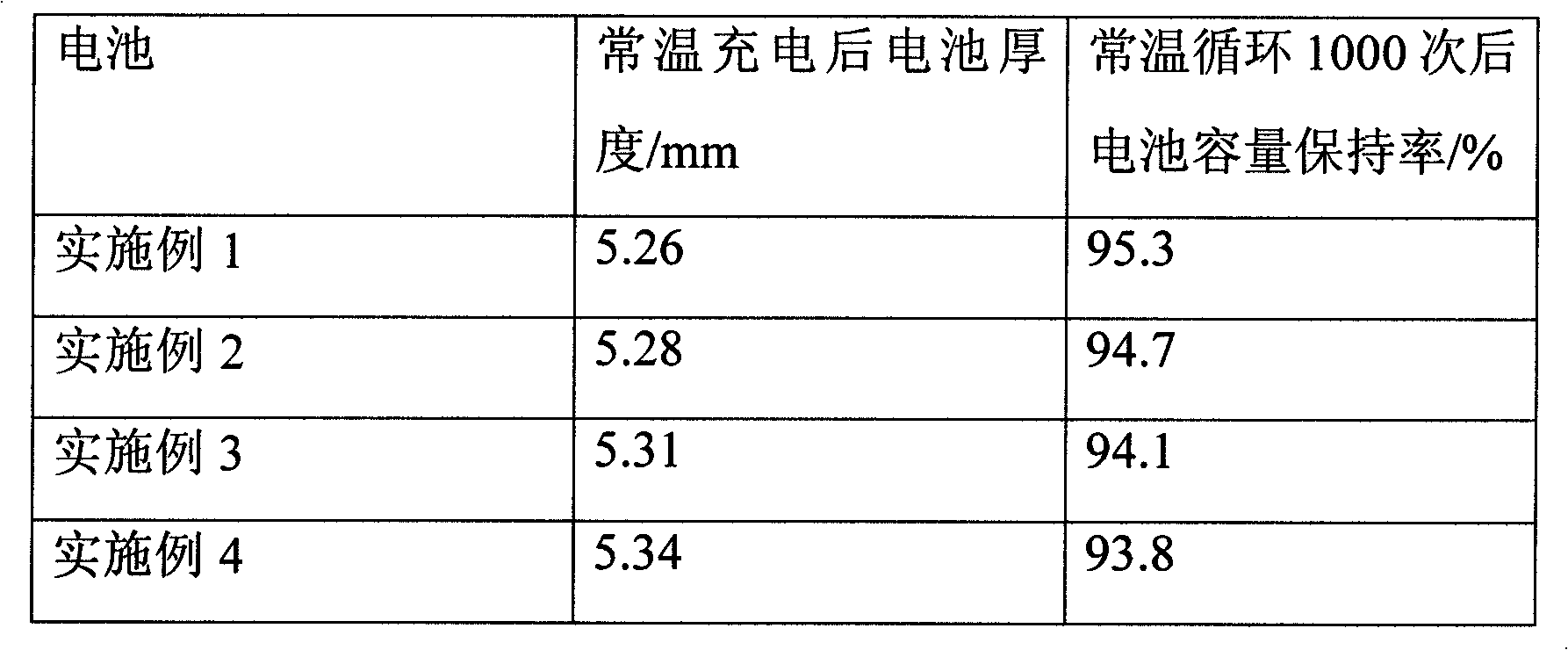

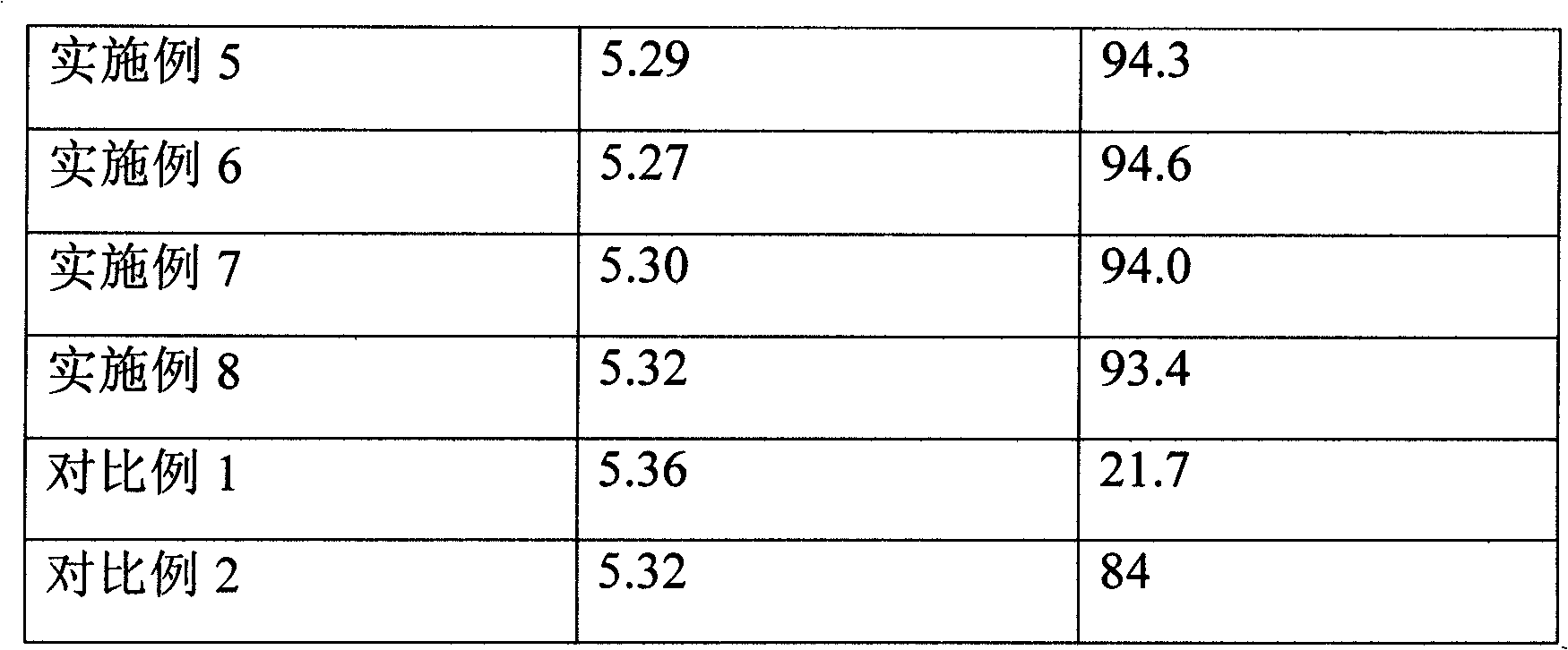

Examples

Embodiment 1

[0028] Production of the positive electrode sheet: the LiCoO 2 , acetylene black and PVDF are dissolved in N-methylpyrrolidone at a weight ratio of 100:7:4.5, stirred evenly, coated on aluminum foil, baked at a temperature of 90±5°C, and rolled to a certain Thickness, roll and cut into positive electrode sheet.

[0029] The production of the negative electrode sheet: the Li 4 Ti 5 o 12 , Activated carbon fiber (aperture ratio is about 85%, specific surface area is about 1800m 2 / g, the pore diameter is about 1nm), acetylene black and PVDF are dissolved in N-methylpyrrolidone at a weight ratio of 100:2:2:6, stirred evenly and coated on copper foil, baked at a temperature of 90± 5°C, use a tablet press to roll to a certain thickness, roll and cut into positive electrode sheets.

[0030] The above-mentioned positive and negative electrode sheets and a polypropylene (PP) separator with a thickness of 25 μm are wound into a square lithium-ion cell and stored in a square batter...

Embodiment 2

[0032] Positive and negative plates and batteries are prepared in the same manner as in Example 1, except that the aperture ratio used in the production of the negative plate is about 82%, and the specific surface area is about 1600m 2 / g, activated carbon fibers with a pore size of about 0.5nm.

Embodiment 3

[0034] The same method as in Example 1 is used to prepare positive and negative electrode sheets and batteries, except that the aperture ratio used in the production of the negative electrode sheet is about 89%, and the specific surface area is about 1900m 2 / g, activated carbon fibers with a pore size of about 5 nm.

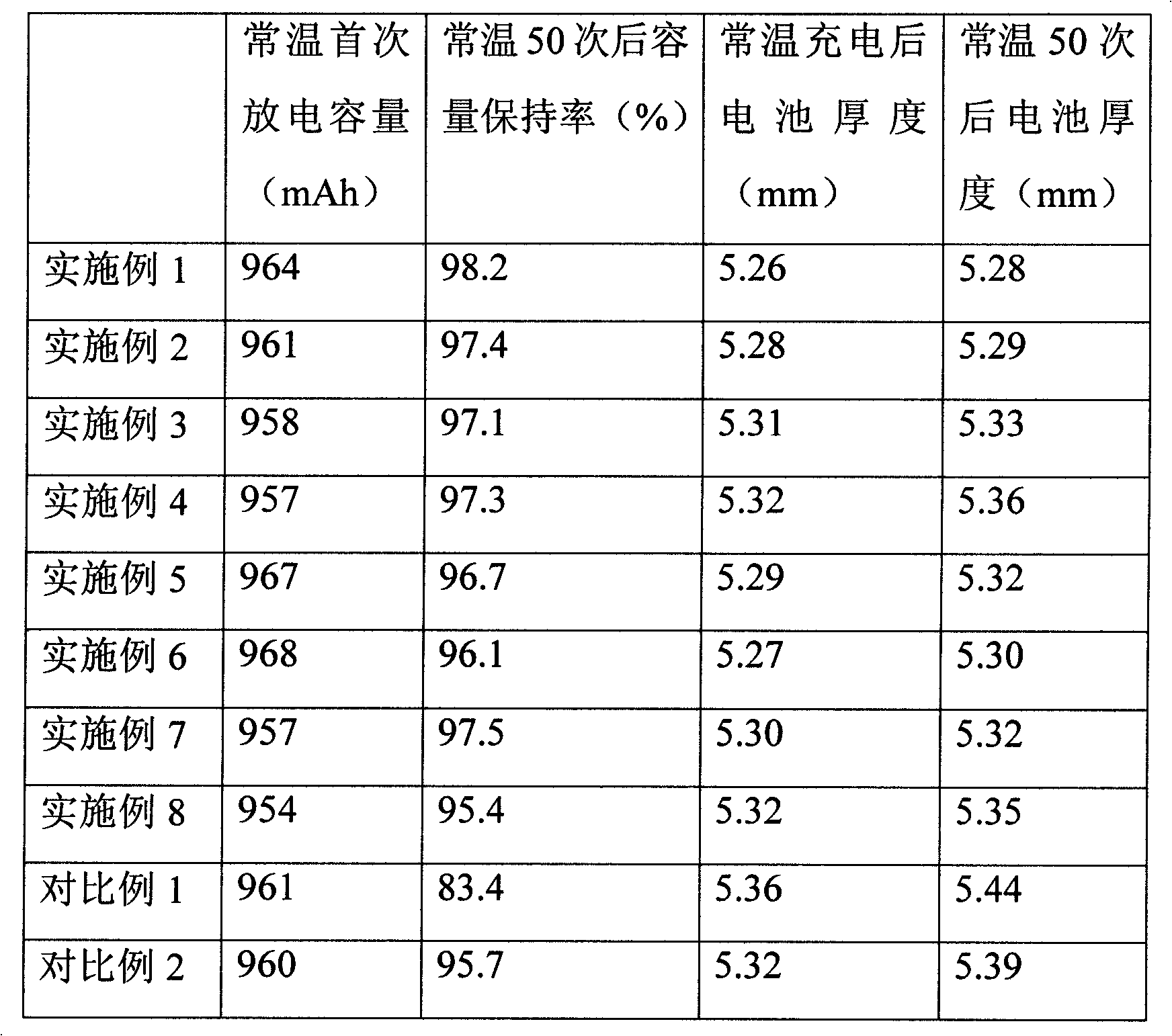

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com