Biodegradable thermoplastic starch resin, preparation method thereof and products thereof

A thermoplastic starch and biodegradation technology, applied in the field of biodegradable thermoplastic starch resin and its preparation, can solve the problems of long degradation induction period, poor effect, and unsatisfactory cost, and achieve the effect of cheap price and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

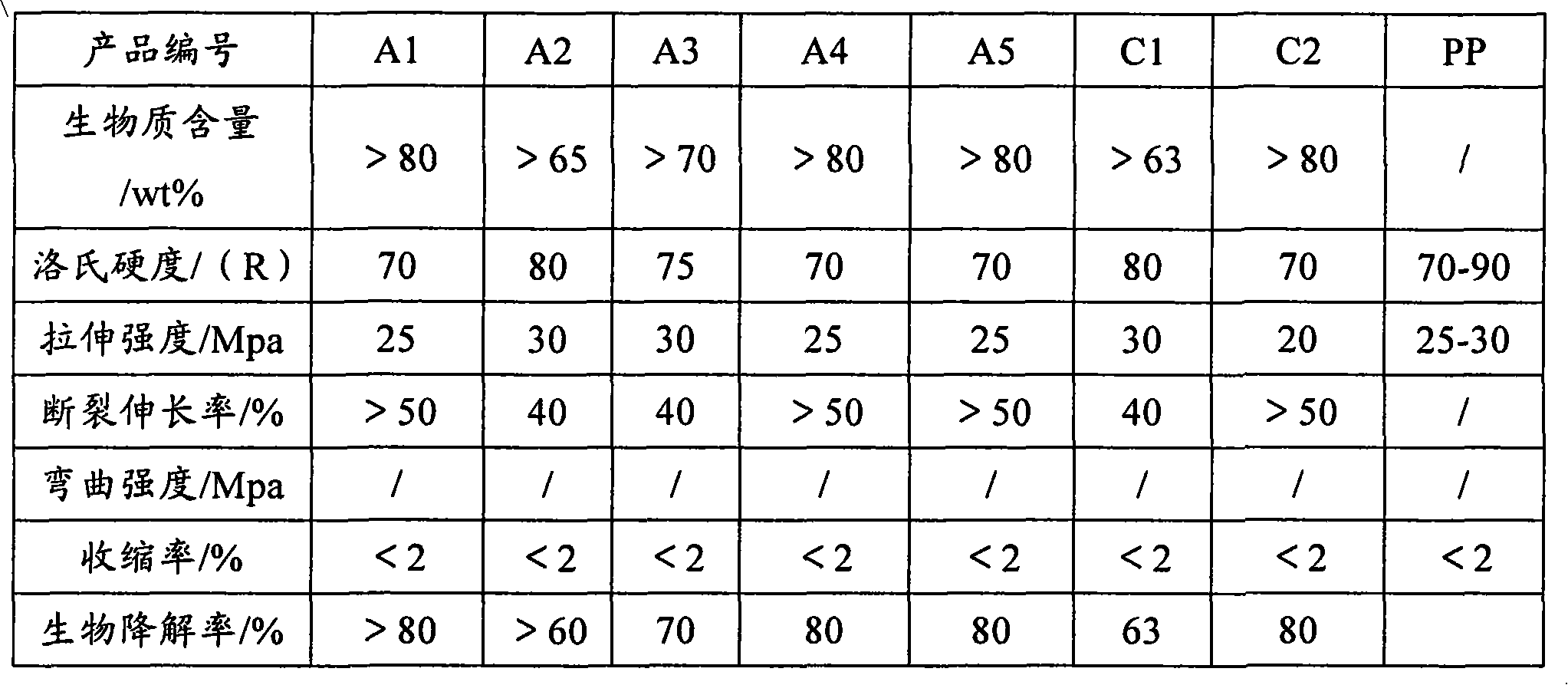

Examples

Embodiment 1

[0024] This example is used to illustrate the biodegradable thermoplastic starch resin provided by the present invention and its preparation method.

[0025] The raw materials are: 60 kg of food grade corn starch, 15 kg of diethylene glycol, 1 kg of stearic acid, 2 kg of calcium stearate, 1 kg of monoglyceride, 2 kg of titanium dioxide, 10 kg of ethylene-acrylic acid copolymer, high Melt finger polypropylene 5 kg and low melt finger polypropylene 10 kg. Among them, the water content of cornstarch is 13wt%; the density of monoglyceride is 0.916g / cm 3 , the ester content is 30%; the number average molecular weight of the ethylene-acrylic acid copolymer is 150,000, the molecular weight distribution is 1.2, the melt index is 15 g / 10 minutes (190 ° C, 2.16 kg), and the density is 0.925 g / cm 3 , the content of acrylic acid is 8%; the number-average molecular weight of high-melting polypropylene is 100,000, the molecular weight distribution is 1.2, the melt index is 28 g / 10 minutes,...

Embodiment 2

[0032] This example is used to illustrate the biodegradable thermoplastic starch resin provided by the present invention and its preparation method.

[0033] The raw materials are: 56 kg of food grade wheat starch, 20 kg of diethylene glycol, 1.2 kg of stearic acid, 1.8 kg of calcium stearate, 1 kg of monoglyceride, 1.5 kg of titanium dioxide, 18 kg of ethylene-acrylic acid copolymer, high Melt finger polypropylene 8 kg and low melt finger polypropylene 12 kg. Among them, the water content of cornstarch is 13wt%; the density of monoglyceride is 0.916g / cm3 , the ester content is ≥ 30%; the number average molecular weight of the ethylene-acrylic acid copolymer is 200,000, the molecular weight distribution is 1.2, the melt index is 15 g / 10 minutes (190 ° C, 2.16 kg), and the density is 0.95 g / cm 3 , the content of acrylic acid is 10%; the number-average molecular weight of high-melting polypropylene is 150,000, the molecular weight distribution is 1.2, the melt index is 25 g / 10 m...

Embodiment 3

[0040] This example is used to illustrate the biodegradable thermoplastic starch resin provided by the present invention and its preparation method.

[0041] The raw materials are: 65 kg of food grade potato starch, 10 kg of diethylene glycol, 1.3 kg of stearic acid, 1.5 kg of calcium stearate, 1.5 kg of monoglyceride, 0.8 kg of titanium dioxide, 16 kg of ethylene-acrylic acid copolymer, high Melt finger polypropylene 10 kg and low melt finger polypropylene 7 kg. Among them, the water content of starch is 14wt%; the density of monoglyceride is 0.92g / cm 3 , the ester content is ≥ 30%; the number average molecular weight of the ethylene-acrylic acid copolymer is 200,000, the molecular weight distribution is 1.2, the melt index is 15 g / 10 minutes (190 ° C, 2.16 kg), and the density is 0.94 g / cm 3 , the content of acrylic acid is 9%; the number average molecular weight of high melting point polypropylene is 80,000, the molecular weight distribution is 1.2, the melt index is 30 g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com