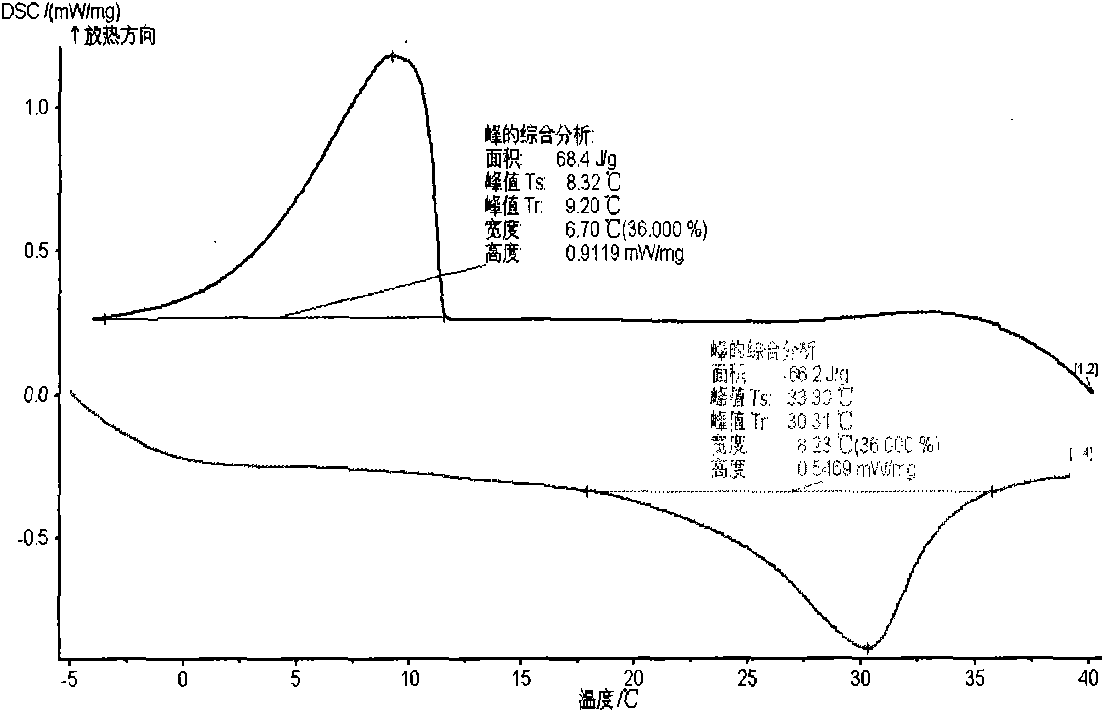

Preparation method of hase change cold accumulation material for keep-alive transportation of penaeus vannamei boone

A phase change cold storage, white shrimp technology, applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problems of low thermal conductivity, low energy storage density, high price, and achieve increased transportation density, high latent heat of phase change, The effect of saving transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The technical solution adopted by the present invention to solve the technical problem is a preparation method of a phase-change cold storage material for the ecological ice-temperature preservation transportation of Penaeus vannamei, comprising the following steps:

[0022] a. Mix distilled water and anhydrous sodium sulfate at a mass ratio of 1.53:1, place in a constant temperature water bath at 40°C, stir and dissolve for 30 minutes, until there is no obvious precipitation in the lower part, and a mixed solution is formed.

[0023] b. Add sodium chloride, and the mass ratio of sodium chloride to anhydrous sodium sulfate is 0.45:1. Then add silicon dioxide and sodium tetraborate, the mass ratio of which is 0.18:1 to anhydrous sodium sulfate, and stir evenly; sodium chloride should be added slowly along the edge of the vortex stirred by the stirrer.

[0024] c. Add CMC to the sol obtained in step b, the mass ratio to anhydrous sodium sulfate is 0.04:1, adjust the stirr...

Embodiment 1

[0029] Fabrication of phase change cold storage materials.

[0030] Take 58mL of distilled water, heat it in a water bath to 40°C and place it at a constant temperature, accurately weigh 38g of anhydrous sodium sulfate, slowly add it to the constant temperature water, stir and dissolve for 30 minutes, until there is no obvious precipitation in the lower part. Weigh 17g of sodium chloride and slowly add it along the edge of the vortex stirred by the stirrer. Then accurately weigh 3 g each of silicon dioxide and sodium tetraborate, add to the solution, and stir. Finally, weigh 1.5g of CMC, slowly add it into the solution, adjust the stirrer to a higher speed, and stir at a constant temperature of 40°C for 3 to 4 hours, until the mixed solution system is stable and milky white gel-like, and no obvious salt particles exist. Put the mixed solution into an ultrasonic oscillator and sonicate for 2 hours until there are no crystals and particle precipitates (at this time, there is no...

Embodiment 2

[0033] Material insulation experiment.

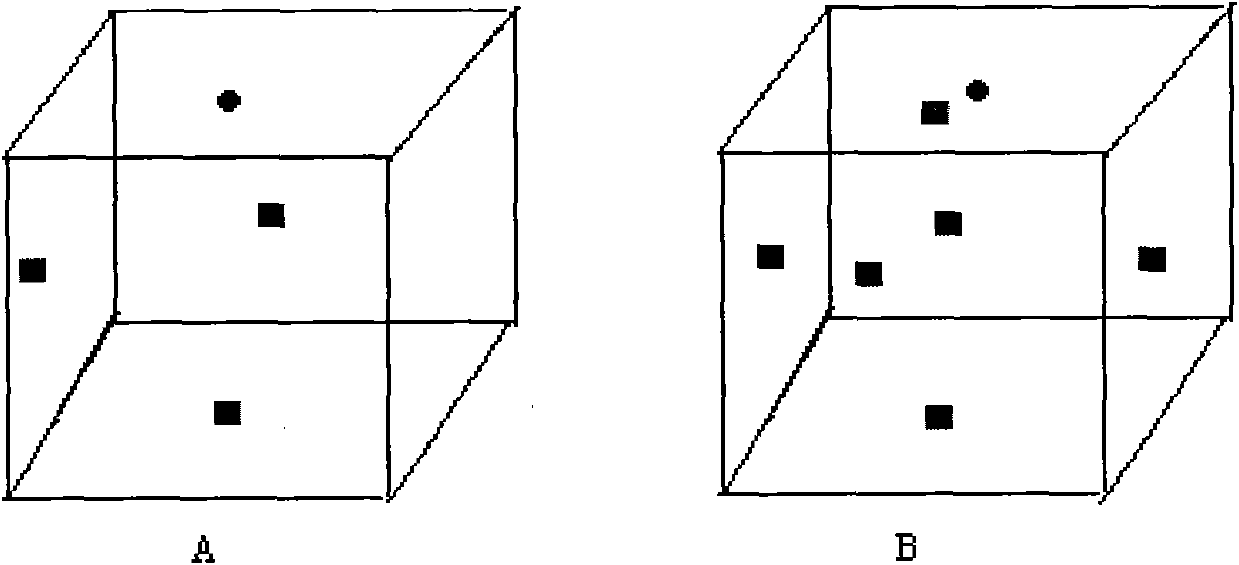

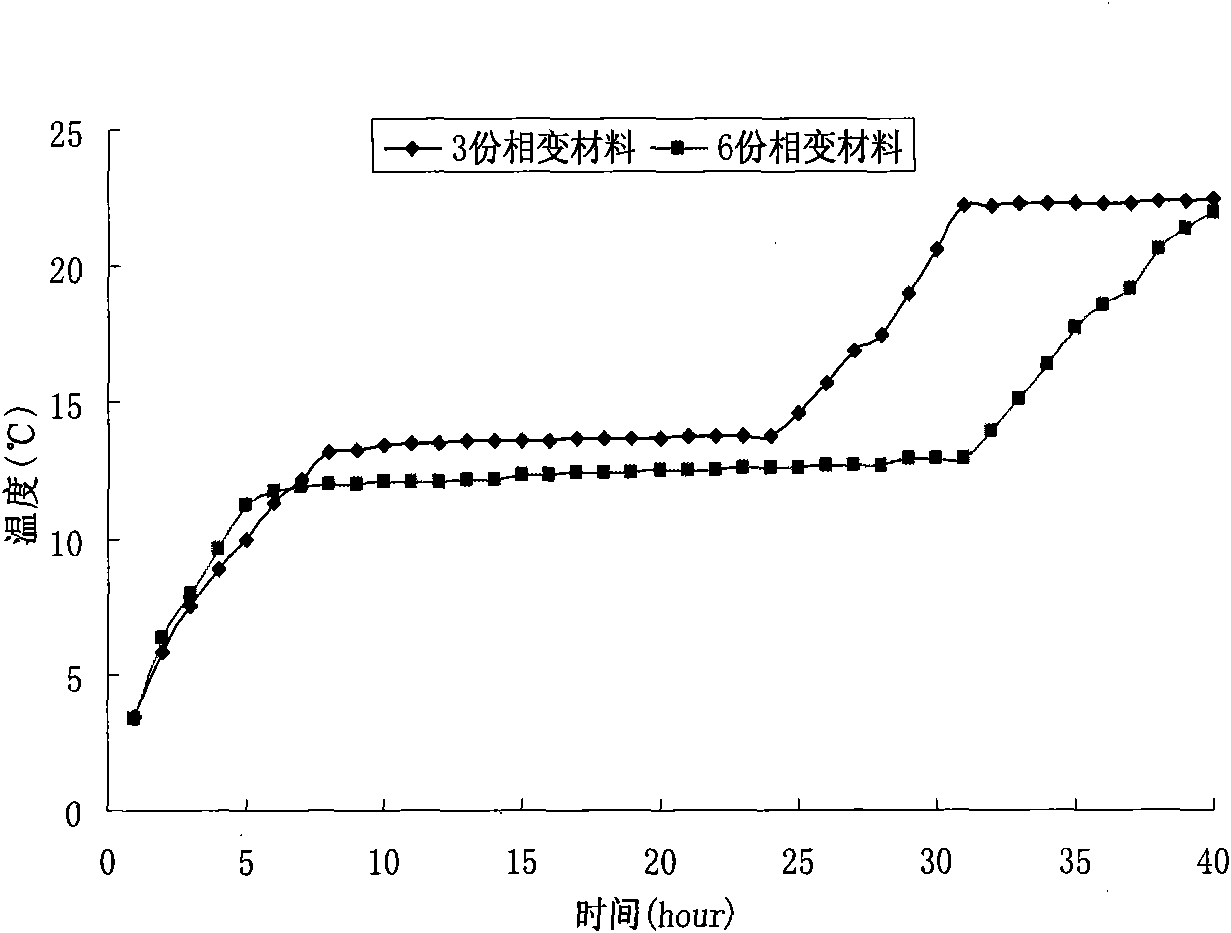

[0034] according to figure 2 In the phase change material heat preservation experiment, the design method of placing the heat preservation bag according to the diagram is used for the test. The size of the heat preservation box is 400mm×220mm×275mm. Only 3 parts of phase change materials are placed in picture A, and 6 parts of materials are placed in picture B. After putting the phase change cold storage material into the incubator, seal it with adhesive tape. The incubator is placed in a room with a constant temperature of 25°C. The automatic temperature recorder record is set to 2min / time, and the temperature is recorded, and then the probe is inserted into the incubator along the blue hole in the middle, placed in the air, and the temperature data is collected at any time, and placed for 3 Days later, it was taken out for data processing.

[0035] After the incubator was placed in a constant temperature room at 25°C for 2 days, it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com