Lithium titanate cathode material and preparation method thereof and lithium ion battery using lithium titanate cathode material

A negative electrode material, lithium titanate technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of easy gas production, affecting the performance stability of lithium-ion batteries, etc., to reduce the contact interface, reduce the reaction, good The effect of performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Heat 0.2L of deionized water to 40°C, add 2g of potassium fluozirconate (K 2 ZrF 6 ), after dissolving, add 0.2g reaction auxiliary boric acid (H 3 BO 3 ), add 100g lithium titanate (Li 4 Ti 5 o 12 ) powder, react at a constant temperature for 9 hours to obtain a hydrolysis reaction product; wash the reaction product and dry it in an oven at 85°C for 4 hours, then place it in a muffle furnace and raise the temperature to 600°C, and keep the temperature constant for 7 hours. Cool naturally to room temperature to obtain a lithium titanate negative electrode material coated with zirconium oxide.

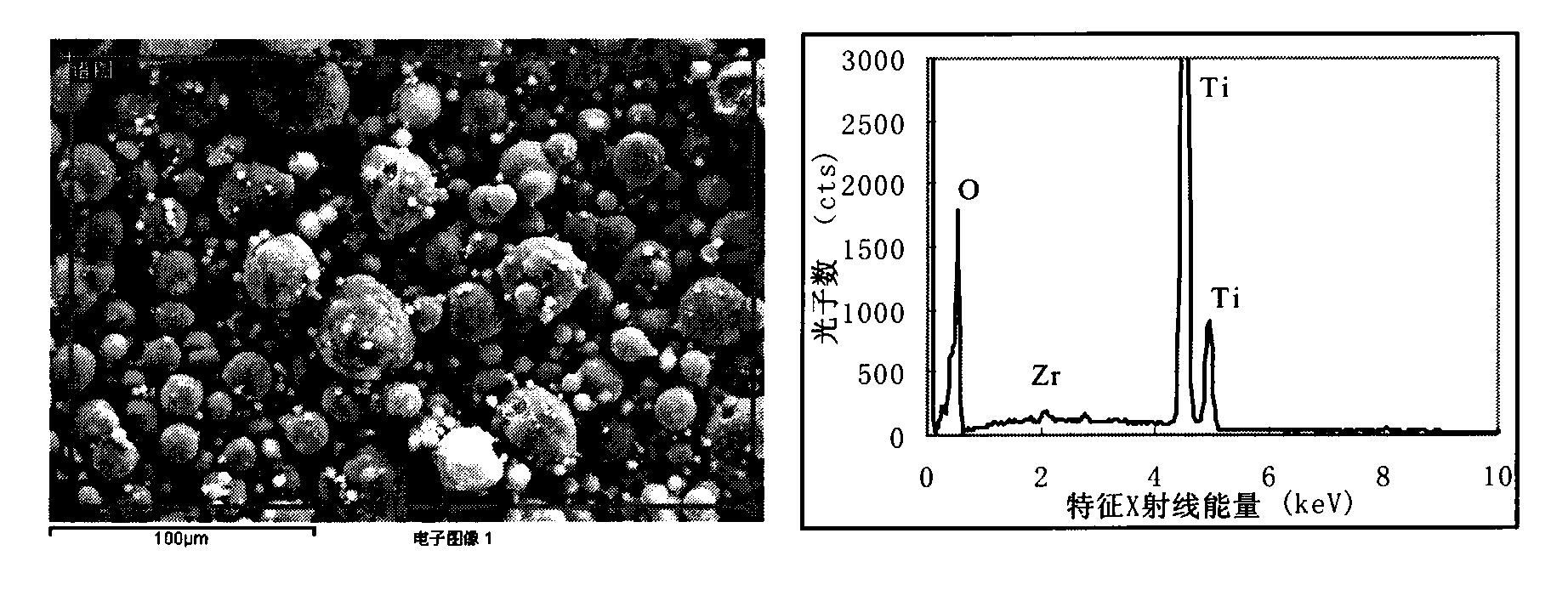

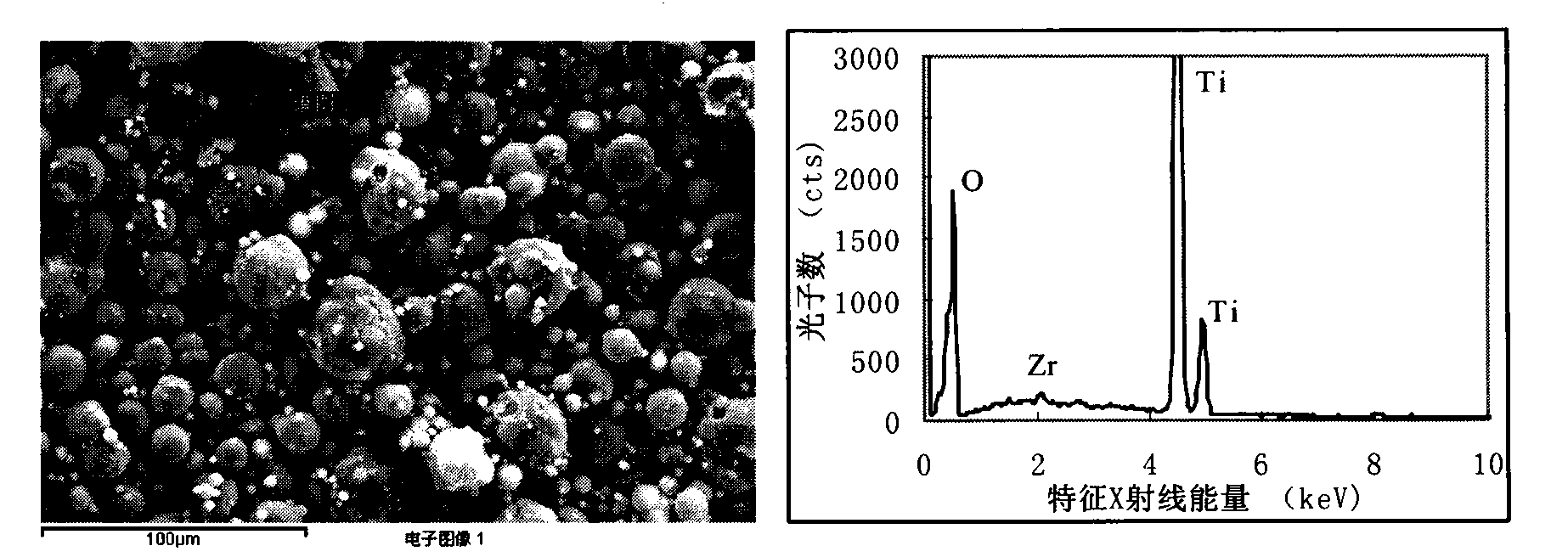

[0029] Use EDS to test the zirconium element of the lithium titanate negative electrode material obtained according to embodiment 1, and its surface test and point test patterns are respectively as follows figure 1 and figure 2 As shown, the mass percentage of zirconium oxide is 0.84%.

[0030] Using the lithium titanate negative electrode material of Example 1 of the pr...

Embodiment 2

[0032] Heat 0.2L of deionized water to 80°C, add 10g of sodium metaaluminate (NaAlO 2 ), after dissolving, add 0.5g reaction auxiliary acetic acid (CH 3 COOH), add 100g lithium titanate (Li 4 Ti 5 o 12 ) powder, react at a constant temperature for 1 hour to obtain a hydrolysis reaction product; wash the reaction product and place it in an oven at 140° C. to dry for 4 hours, then place it in a muffle furnace and raise the temperature to 800° C. Cool naturally to room temperature to obtain a lithium titanate negative electrode material coated with aluminum oxide. The mass percent content of aluminum oxide is 6.1%.

[0033] The preparation and storage test of the lithium-ion battery are the same as in Example 1, and the test results show that the thickness expansion of the lithium-ion battery using the lithium titanate negative electrode material coated with aluminum oxide on the surface of Example 2 of the present invention as the negative electrode active material is 11%. ...

Embodiment 3

[0035] Heat 0.2L of a mixed solvent of deionized water and ethanol (the mass ratio of deionized water to ethanol is 95:5) to 60°C, add 30g of magnesium chloride (MgCl 2 ), after dissolving, add 2.5g reaction auxiliary carbonic acid (H 2 CO 3 ), add 100g lithium titanate (Li 4 Ti 5 o 12 ) powder, react at a constant temperature for 5 hours to obtain a hydrolysis reaction product; wash the reaction product and dry it in an oven at 180°C for 2 hours, then place it in a muffle furnace and raise the temperature to 900°C, and keep the temperature constant for 1 hour. Cool naturally to room temperature to obtain a lithium titanate negative electrode material coated with magnesium oxide. The mass percent content of magnesium oxide is 12.5%.

[0036]The preparation and storage test of the lithium-ion battery are the same as in Example 1. The test results show that the thickness expansion of the lithium-ion battery using the lithium titanate negative electrode material coated with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com