Preparation method of semi-spherical active carbon electrode material of super capacitor

A technology for supercapacitors and electrode materials, which is applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of low migration rate of electrolyte electrolyte and limit the charge and discharge power of supercapacitors, that is, power density, etc., and achieve increased pore size and reaction conditions Gentle, easy-to-step results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Preparation of hemispherical activated carbon: first dissolve 10% glucose in deionized water, then add 1g of foaming agent sodium lauryl sulfate, transfer it to an autoclave after it is completely dissolved, and react under hydrothermal conditions at 100°C for 7h. The product was washed, filtered, and dried, and then carbonized at 700°C for 3 hours under the protection of a reducing atmosphere. Natural cooling and grinding to obtain hemispherical activated carbon. figure 1 For the SEM photograph of the sample, from figure 1 A clear hemispherical structure can be seen. The hemispherical activated carbon prepared by this method has a specific surface area of 911.21m 2 / g.

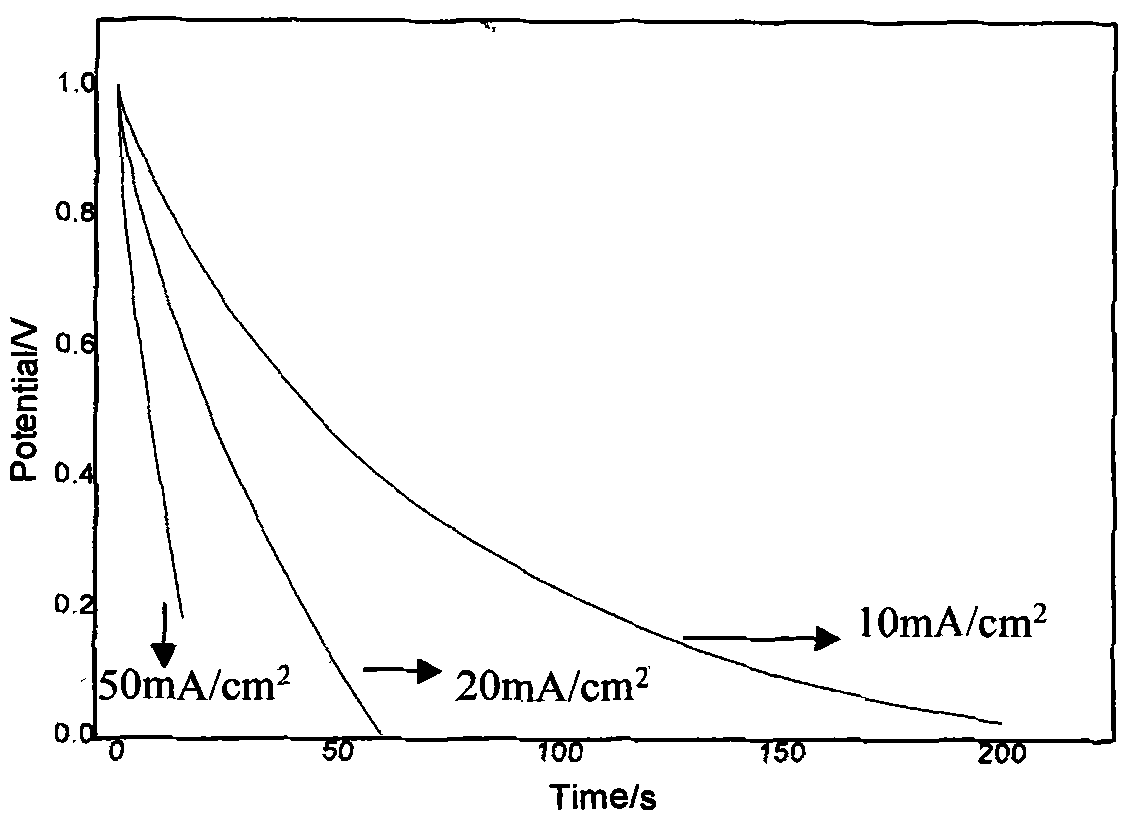

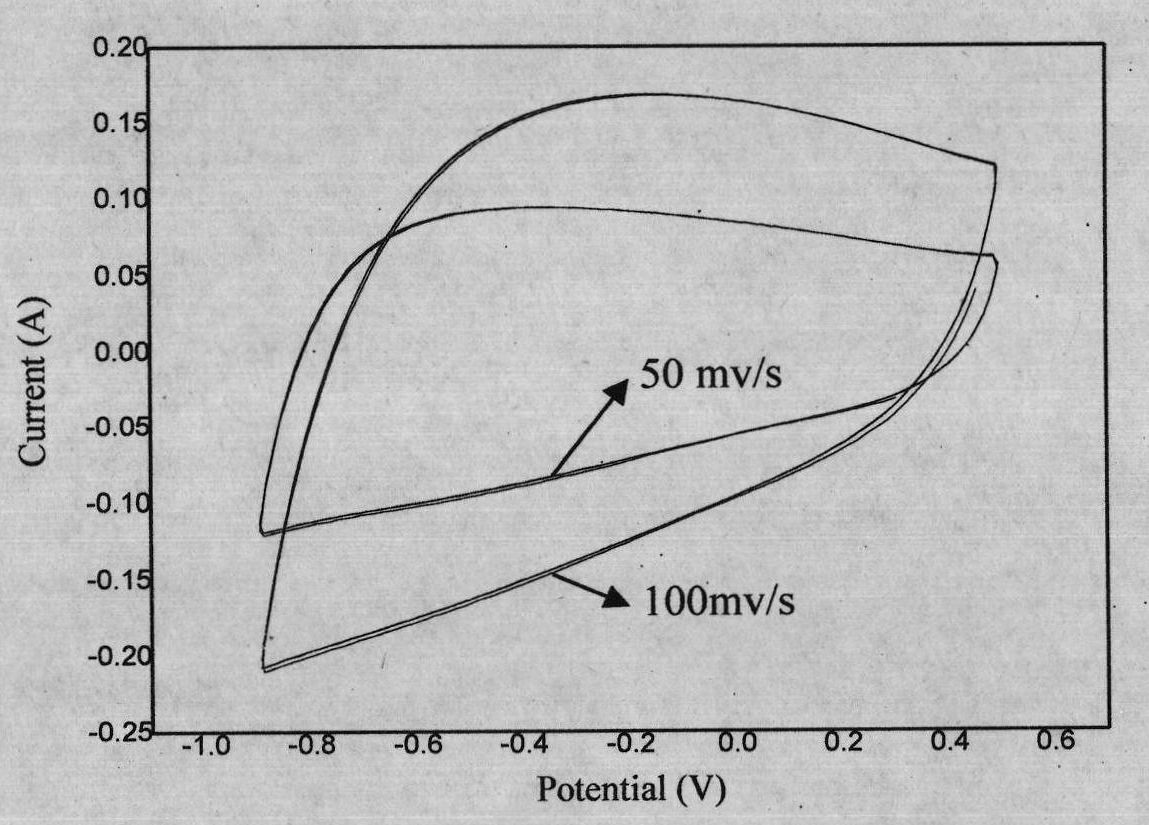

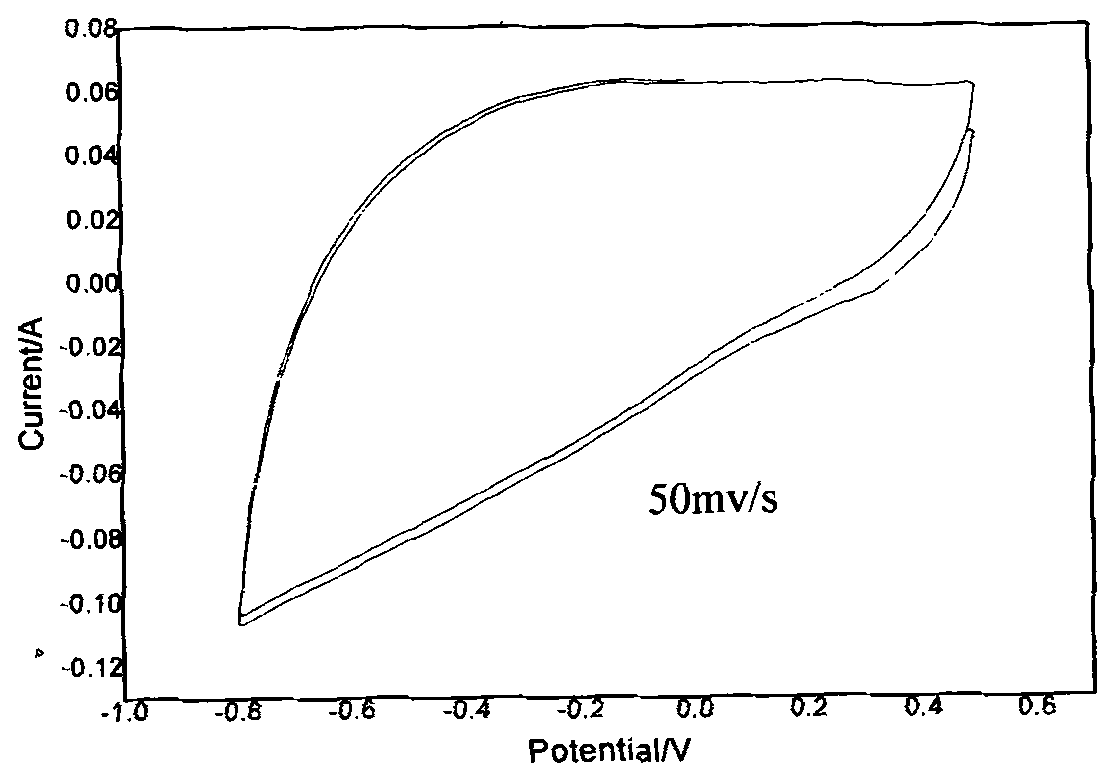

[0015] Preparation of activated carbon electrode: Mix activated carbon, carbon black and polytetrafluoroethylene emulsion according to the mass ratio of 65:30:5, adjust it into a slurry, and evenly coat it on the foamed nickel, use a powder tablet press with 15MPa Press the electrode sheet into a...

Embodiment 2

[0017] Preparation of hemispherical activated carbon: Dissolve glucose in deionized water first, then add 1 g of foaming agent sodium bicarbonate, transfer to autoclave after complete dissolution, and react at 160°C for 9 hours under hydrothermal conditions. The product was washed, filtered, and dried, and then carbonized at 850°C for 3 hours under the protection of a reducing atmosphere. Natural cooling and grinding to obtain hemispherical activated carbon. The hemispherical activated carbon prepared by this method has a specific surface area of 851.75m 2 / g.

[0018] Preparation of activated carbon electrode: Mix activated carbon, carbon black and polytetrafluoroethylene emulsion according to the mass ratio of 65:30:5, adjust it into a slurry, and evenly coat it on the foamed nickel, use a powder tablet press with 15MPa Press the electrode sheet into a sheet, and then put the electrode sheet into a vacuum drying oven at 120°C for 24 hours to vacuum dry. The saturated ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com