Cerium copper titanium composite oxide catalyst for flue gas denitration, preparation method and using method

A technology of composite oxides and catalysts, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of selectivity, sulfur resistance, poor water resistance, and activity low cost, simple use conditions and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 4g Ce(SO 4 ) 2 4H 2 O, 2.47g CuSO 4 ·5H 2 O and 19.00g Ti(SO 4 )2·2H 2 O was dissolved in deionized water, and 20% concentrated ammonia water was added dropwise at a rate of 0.3mL / min under stirring conditions to adjust the pH=9.5. After washing and filtering to remove sulfate ions, place it in a water bath at 80°C for 4 hours, and place it in a vacuum drying oven. Dry at 50°C for 12 hours and then dry at 110°C for 4 hours. Finally, the sample was calcined at 500° C. for 5 hours to obtain the catalyst sample. All samples were sieved into 40-60 mesh size particles and powder for later use.

Embodiment 2

[0027] Put 0.05g of the catalyst powder sample of Example 1 into a physical / chemical adsorption apparatus for BET testing. The test was carried out by the AUTOSORB-1-C physical / chemical adsorption instrument produced by Quanta Corporation of the United States. The BET result shows that the specific surface area of the catalyst is 170.6m 2 / g, the total pore volume is 0.458cc / g, and the average pore diameter is

Embodiment 3

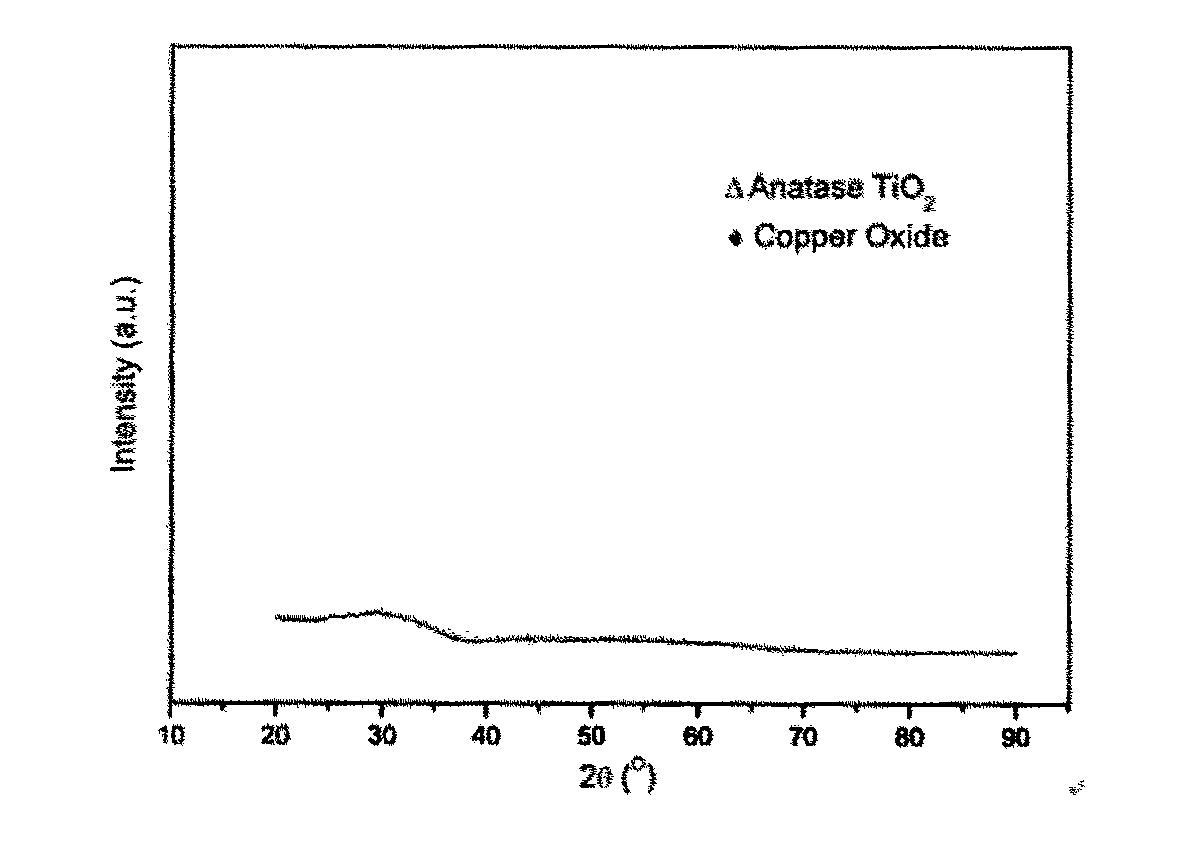

[0029] A certain amount of catalyst powder sample of Example 1 is taken, and X-ray diffraction is performed on the sample, and its diffraction pattern is analyzed to obtain the composition of the material, the structure and shape of the atomic molecules inside the material. The test instrument is X`Pert PRO from PANalytical Company. Analyzing Diffraction Patterns figure 1 It can be seen that the catalyst is in an amorphous form, without the existence of anatase crystal form and copper oxide crystal, and the three elements of cerium, copper and titanium are widely and uniformly distributed on the catalyst, which proves that the catalyst has a cerium-copper-titanium composite oxide crystal structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com