Urban garbage and sludge resource comprehensive utilization system

A technology for urban waste and sludge, applied in the comprehensive utilization system of sludge resources and in the field of urban waste, to achieve the effects of fast flocculation, reduced power consumption, and shortened sewage treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

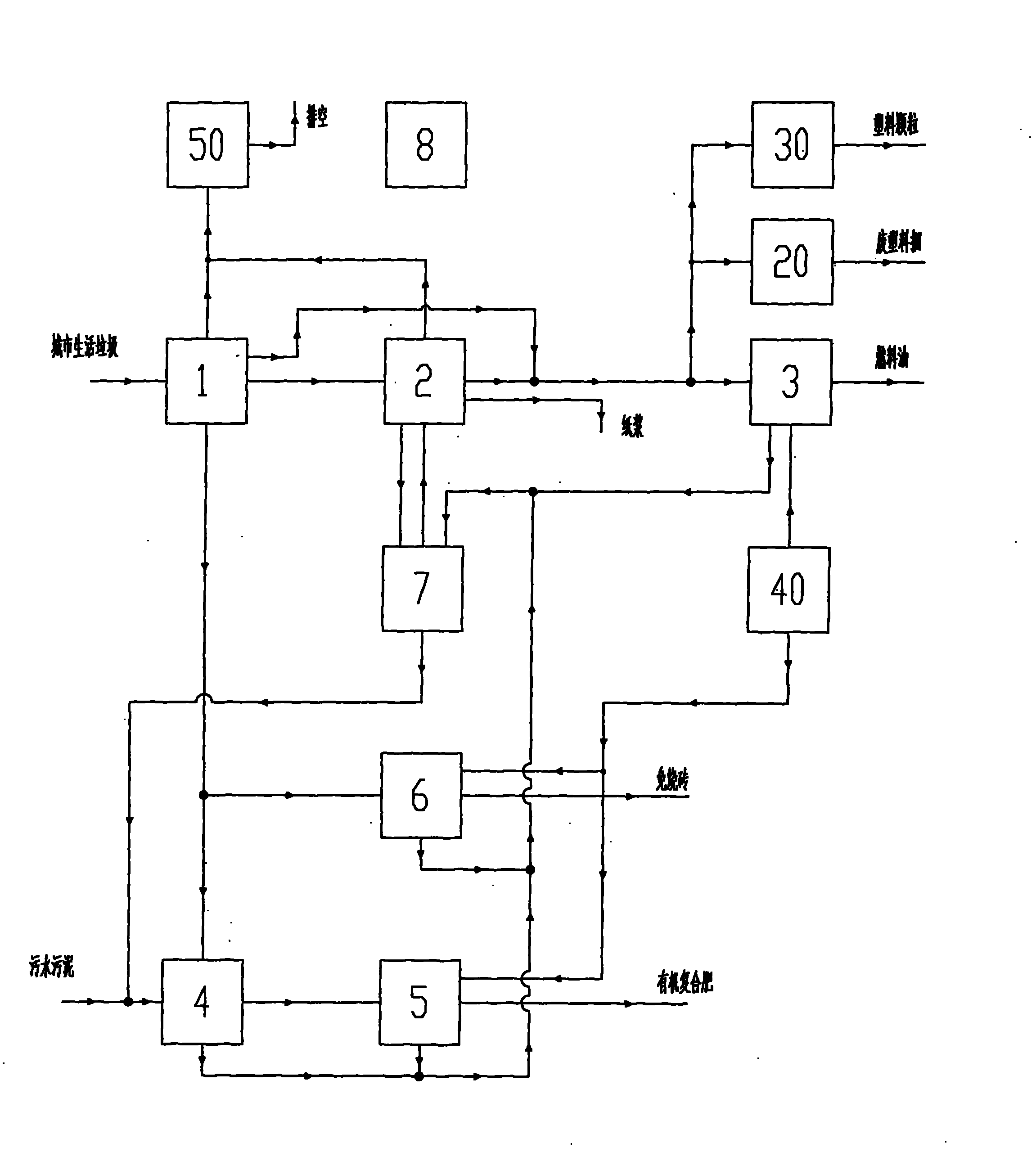

[0070] see figure 1 , the comprehensive utilization system of municipal garbage and sludge resources of the present invention is composed of a set of garbage feeding / sorting equipment 1, pulp recycling equipment 2, waste plastics turning into oil equipment 3, sludge feeding equipment 4, and organic compound fertilizer production equipment 5 , Burn-free brick production equipment 6, sewage treatment equipment 7, automatic control and safety protection equipment 8 and other components.

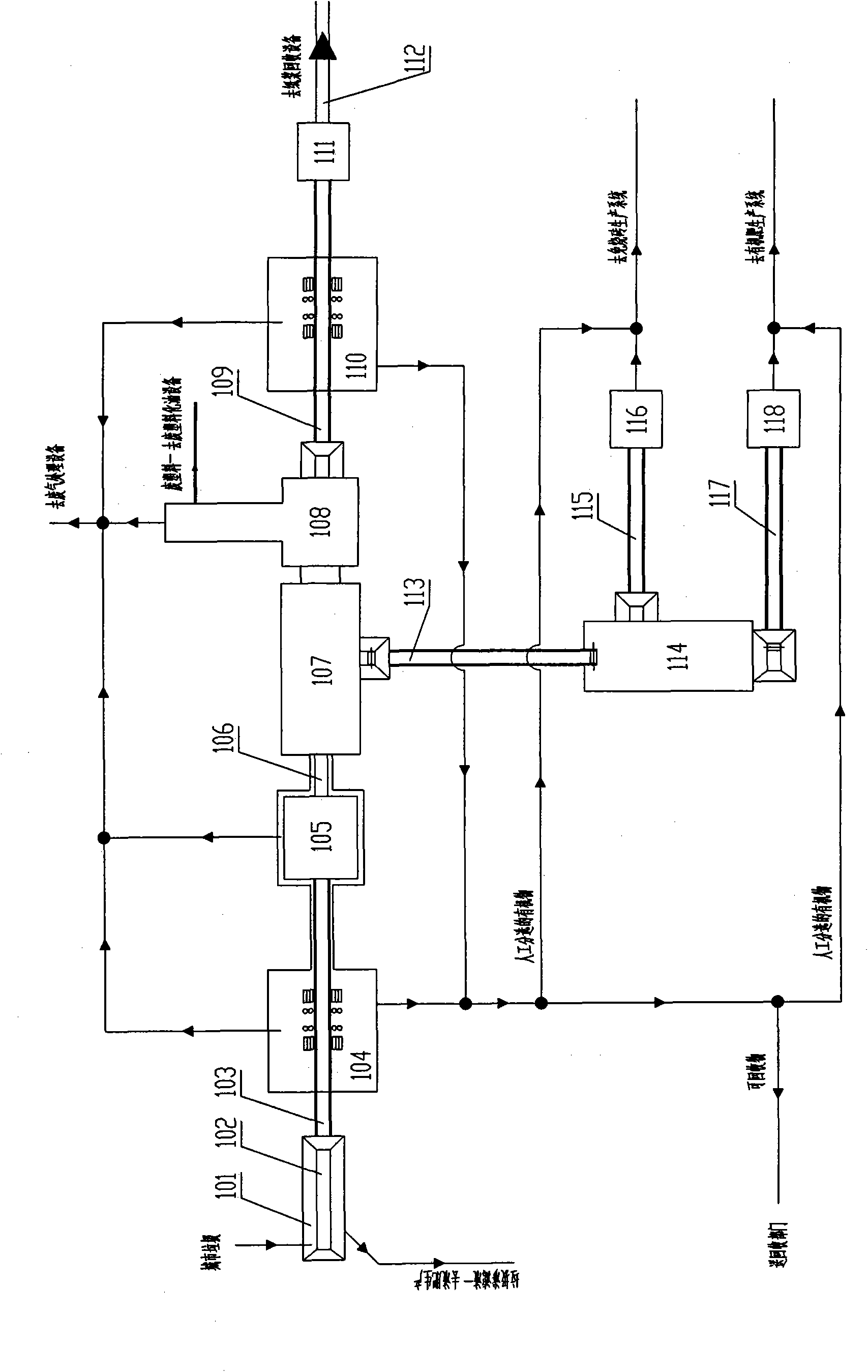

[0071] see figure 2 , Garbage feeding / sorting equipment 1, the municipal garbage is transported by a special garbage vehicle, weighed and poured into the garbage unloading hopper 101, unloaded by the crawler feeder 102, and sent to the first level by the conveying and sorting conveyor belt 103 In the sorting room 104, there is a manual sorting station in the sorting room, which separates large items such as tables, chairs, wood, rubber tires and metals, glass bottles, bricks, cement blocks, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com