Method for preparing sugarcane juice flavor vinegar

A technology of sugarcane juice and flavor, applied in the field of preparation of sugarcane juice flavored vinegar, to achieve the effects of wide sources, high yield, and easy control of the fermentation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

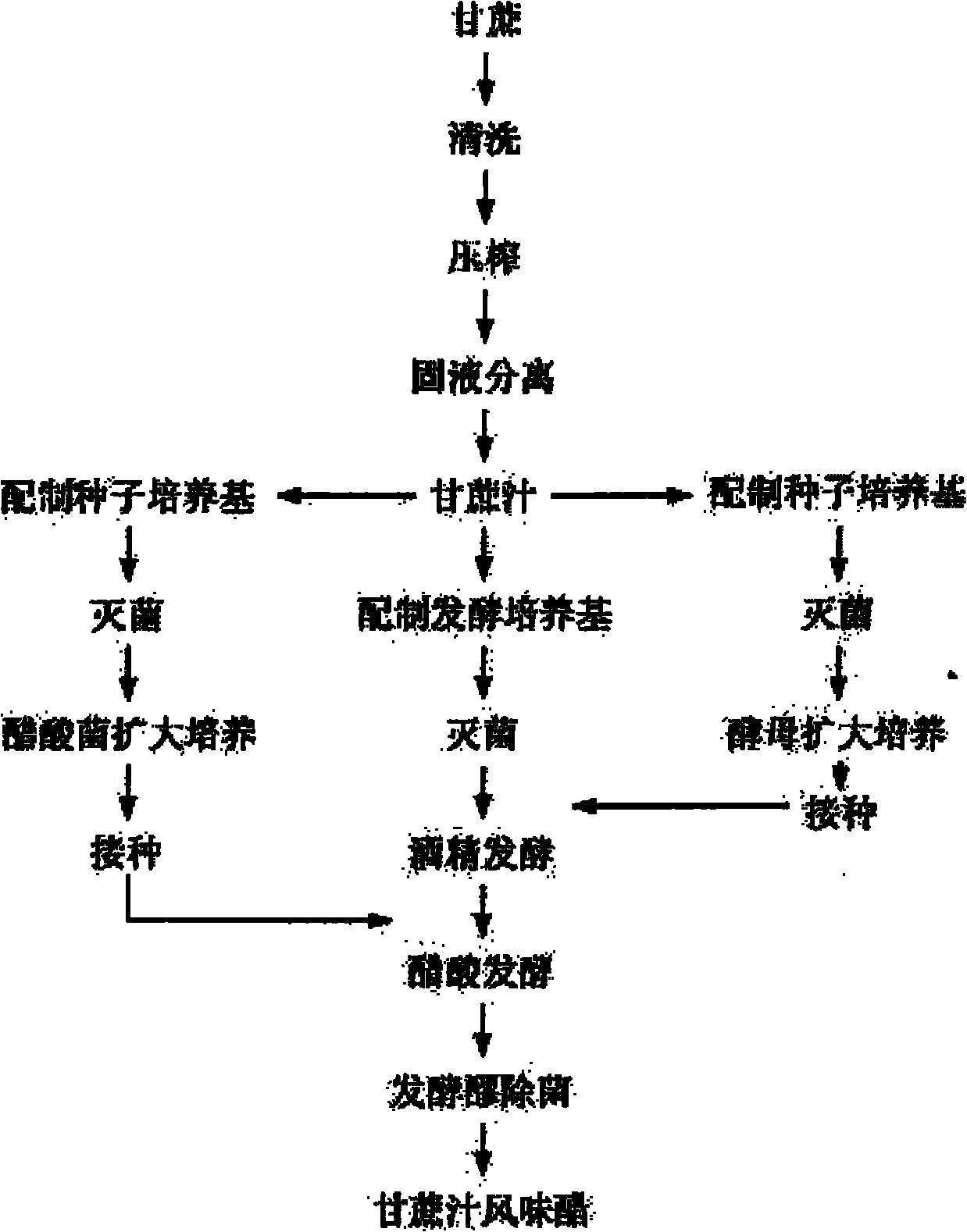

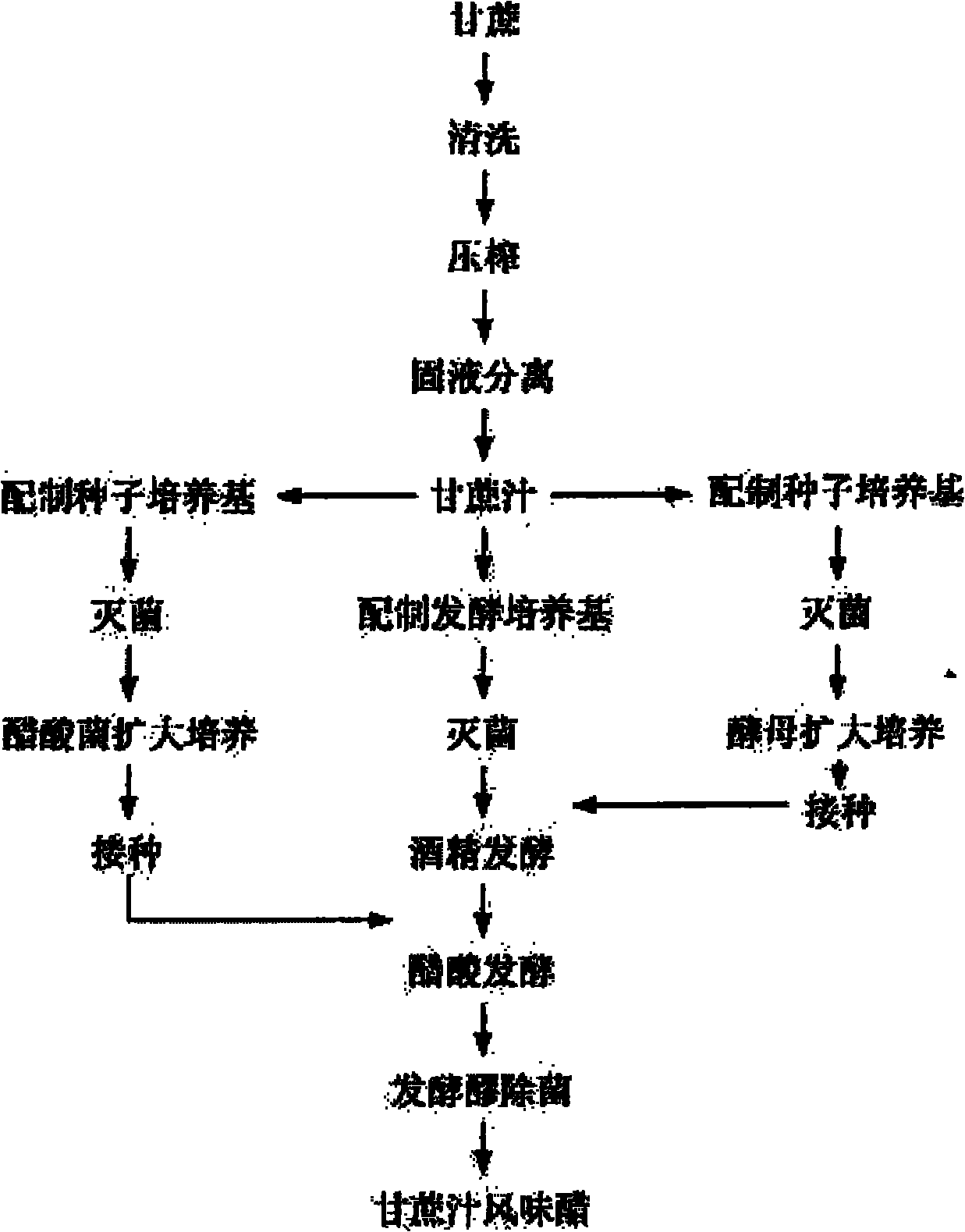

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of fermentation medium

[0032] After the sugarcane is cleaned, squeezed, and separated from solid and liquid, take 5.4L of sugarcane juice (reducing sugar content is 112g / L, fermentable nitrogen content is 0.45g / L), add 115.2g of sucrose and 8.4g of diammonium hydrogen phosphate to make alcohol During fermentation, the initial reducing sugar content was 120g / L and the initial fermentable nitrogen content was 0.7g / L, adjusted to pH 5.0 with acetic acid, put into a 10L fermenter, sterilized at 121°C for 15min, cooled, and set aside.

[0033] (2) Alcoholic fermentation

[0034] The process of expanding yeast culture is as follows: slant → shake flask culture.

[0035] Shake flask culture medium: sugarcane juice 600mL, diammonium hydrogen phosphate 7.0g, pH 5.0 adjusted with acetic acid, divided into three 1000mL Erlenmeyer flasks, sterilized at 121°C for 15min, cooled for later use.

[0036] The slant strains of Saccharomyces cerevisiae CICC31143 (purcha...

Embodiment 2

[0044] (1) Preparation of fermentation medium

[0045] After the sugarcane is cleaned, squeezed and separated from solid and liquid, take 7075mL of sugarcane juice (reducing sugar content is 110g / L, fermentable nitrogen content is 0.40g / L), add 268.7g of sucrose and 17.3g of diammonium hydrogen phosphate to make the alcoholic fermentation When the initial reducing sugar content was 145g / L and the initial fermentable nitrogen content was 0.9g / L, the pH was adjusted to 5.5 with acetic acid, put into a 10L fermenter, sterilized at 121°C for 15min, cooled, and set aside.

[0046] (2) Alcoholic fermentation

[0047] The process of expanding yeast culture is as follows: slant → shake flask culture.

[0048] Shake flask culture medium: sugarcane juice 145mL, diammonium hydrogen phosphate 1.71g, pH 5.5 adjusted with acetic acid, filled into a 1000mL Erlenmeyer flask, sterilized at 121°C for 15min, cooled for later use.

[0049] The slant strains of Saccharomyces cerevisiae CICC31146...

Embodiment 3

[0057] (1) Preparation of fermentation medium

[0058] After the sugarcane is cleaned, squeezed, and solid-liquid separated, take 6.24L of sugarcane juice (reducing sugar content is 114g / L, fermentable nitrogen content is 0.42g / L), add 520g of sucrose and 23.2g of ammonium dihydrogen phosphate, and make alcoholic fermentation When the initial reducing sugar content was 180g / L and the initial fermentable nitrogen content was 0.8g / L, the pH was adjusted to 5.0 with acetic acid, put into a 10L fermenter, sterilized at 121°C for 15min, cooled, and set aside.

[0059] (2) Alcoholic fermentation

[0060] The process of expanding yeast culture is as follows: slant → shake flask culture.

[0061] Shake flask culture medium: 600 mL of sugarcane juice, 12.2 g of ammonium dihydrogen phosphate, adjusted to pH 5.0 with acetic acid, divided into six 500 mL Erlenmeyer flasks, sterilized at 121°C for 15 min, and cooled for later use.

[0062] The slant strains of Hansenula anomalies CICC310...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com