Fermented seedless wampee fruit vinegar as well as preparation method and application thereof

A fermented, fruit vinegar technology, applied in the preparation of vinegar, biochemical equipment and methods, methods based on microorganisms, etc., can solve the problem of low acidity of yellow-skin fruit vinegar, traditional brewing technology, long production cycle of fruit vinegar, etc. problem, to achieve the effect of full body, strong protein stability and strong market potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

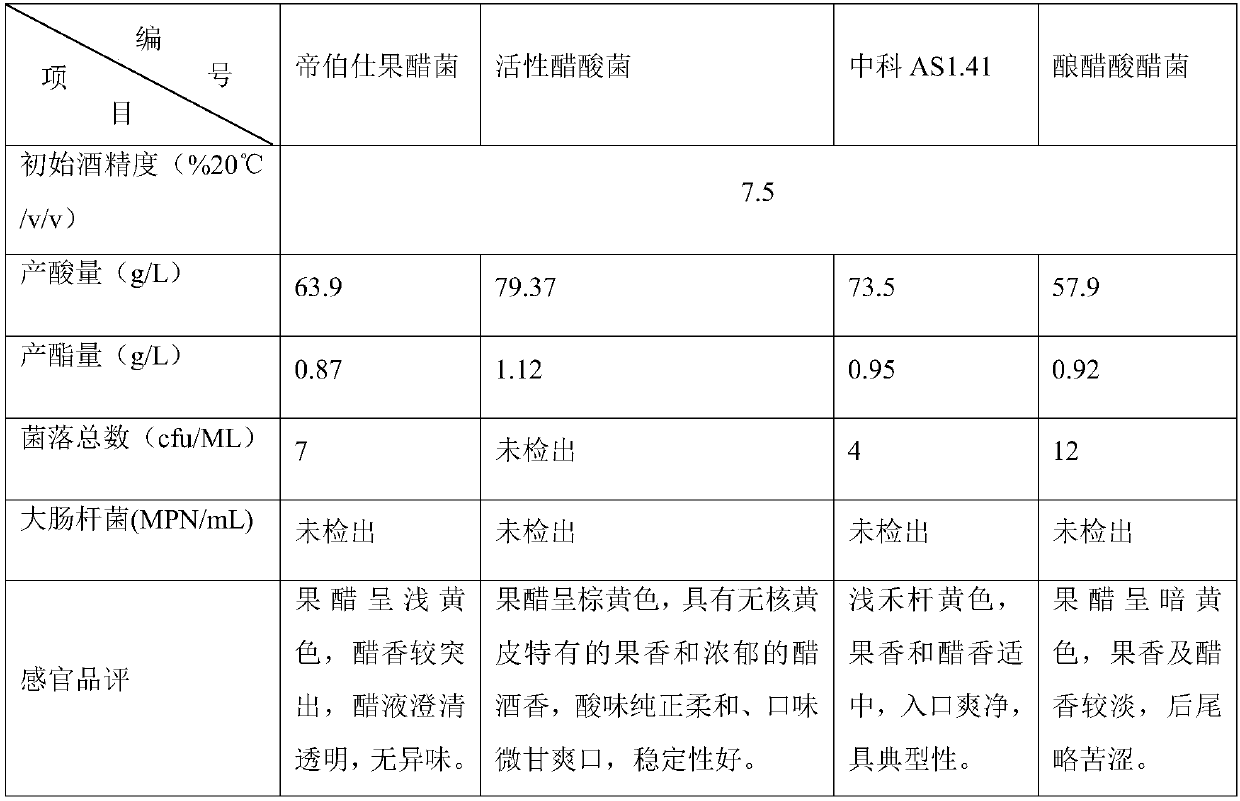

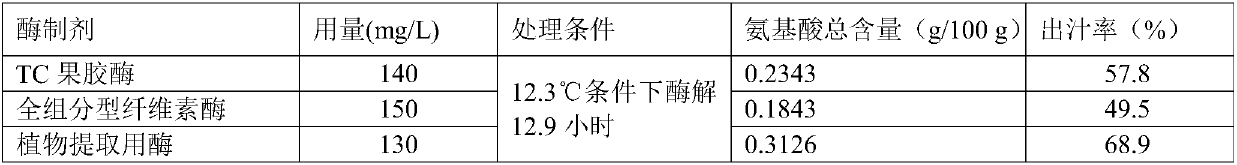

[0063] (1) Raw material selection and enzyme treatment: select medium-ripened high-quality seedless yellow bark with 125-137g / L total sugar and 11-13g / L total acid, wash it with sterilized water, and crush it into a slurry with a screw pump Then add enzyme for plant extraction (Ningxia Hersbit Biotechnology Co., Ltd.) to carry out enzymatic hydrolysis at 11.6°C for 12.5 hours. Wherein, the enzyme for plant extraction is added at a final concentration of 130 mg / L in the enzymatic hydrolysis system.

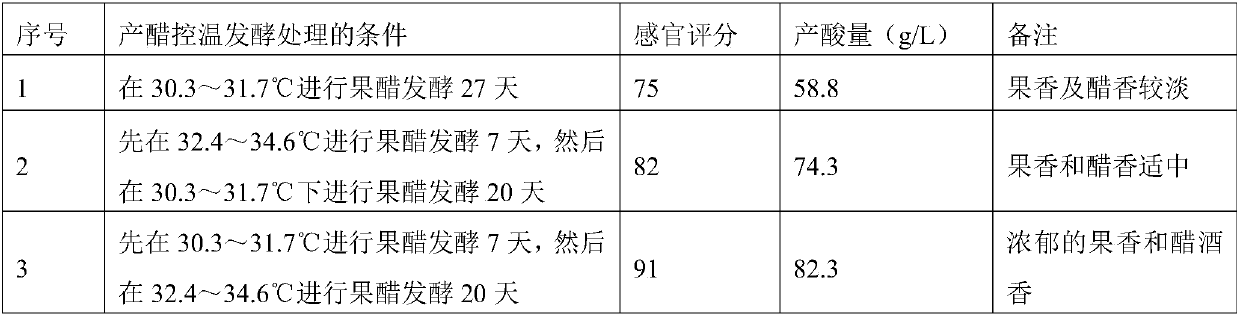

[0064] (2) Alcoholic fermentation and acetic acid fermentation are carried out simultaneously: Active acetic acid bacteria (Jining Yuyuan Biotechnology Co., Ltd., and germination rate: >70%), Schneikamp apple cider vinegar solution (acidity is 54g / L, Beijing Jiashengxing Trading Co., Ltd.) and warm water at a temperature of 30°C were mixed according to the ratio of 1g: 5mL: 12mL, fully stirred and incubated for 2 hours to obtain activated active acetic acid bacteria for use. After...

Embodiment 2

[0069] (1) Raw material selection and enzyme treatment: select medium-ripened high-quality seedless yellow bark with 125-137g / L total sugar and 11-13g / L total acid, wash it with sterilized water, and crush it into a slurry with a screw pump Then add enzyme for plant extraction (Ningxia Hersbit Biotechnology Co., Ltd.) to carry out enzymatic hydrolysis at 12.0°C for 12.9 hours. Wherein, the enzyme for plant extraction is added at a final concentration of 140 mg / L in the enzymatic hydrolysis system.

[0070] (2) Alcoholic fermentation and acetic acid fermentation are carried out simultaneously: Active acetic acid bacteria (Jining Yuyuan Biotechnology Co., Ltd., and germination rate: >70%), Schneikamp apple cider vinegar solution (acidity is 54g / L, Beijing Jiashengxing Trading Co., Ltd.) and warm water at a temperature of 31°C are mixed according to the ratio of 1g: 5mL: 12mL, fully stirred and incubated for 2 hours to obtain activated active acetic acid bacteria for use. After ...

Embodiment 3

[0075] (1) Raw material selection and enzyme treatment: select medium-ripened high-quality seedless yellow bark with 125-137g / L total sugar and 11-13g / L total acid, wash it with sterilized water, and crush it into a slurry with a screw pump Then add enzyme for plant extraction (Ningxia Hersbit Biotechnology Co., Ltd.) to carry out enzymatic hydrolysis at 12.4°C for 13.3 hours. Wherein, the enzyme for plant extraction is added at a final concentration of 140 mg / L in the enzymatic hydrolysis system.

[0076] (2) Alcoholic fermentation and acetic acid fermentation are carried out simultaneously: Active acetic acid bacteria (Jining Yuyuan Biotechnology Co., Ltd., and germination rate: >70%), Schneikamp apple cider vinegar solution (acidity is 54g / L, Beijing Jiashengxing Trading Co., Ltd.) and warm water at a temperature of 32°C were mixed according to the ratio of 1g: 5mL: 12mL, fully stirred and incubated for 2 hours to prepare activated active acetic acid bacteria for use. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com