Biological metallurgy mineral leaching microorganism combined bacterium fluid for copper ore and method for recycling metallic copper

A technology of leaching microorganisms and biometallurgy, which is applied in the direction of improving process efficiency to achieve the effects of reducing production costs, improving resource utilization efficiency, and protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

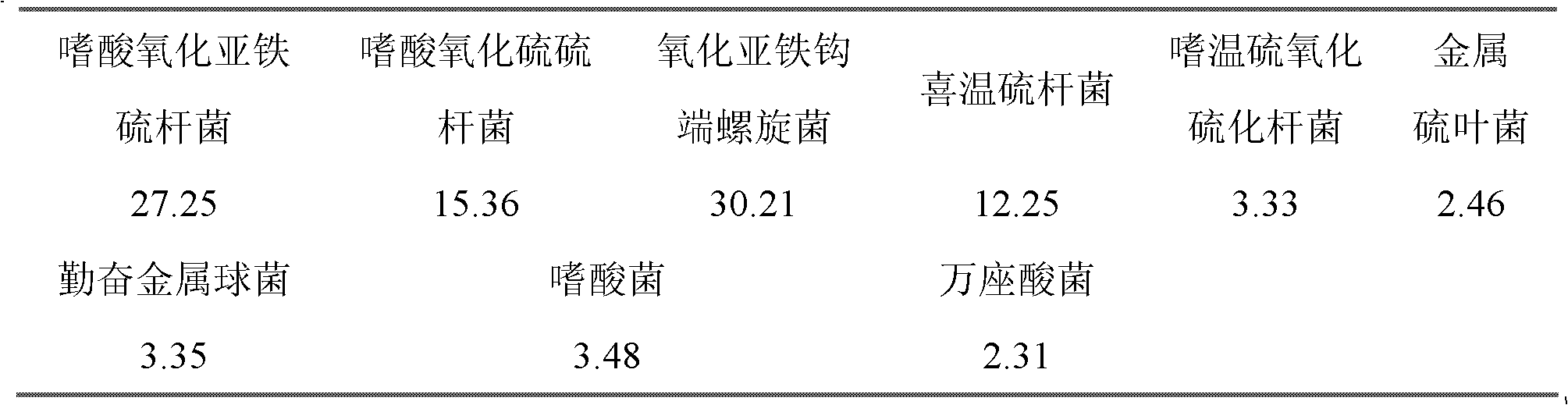

Method used

Image

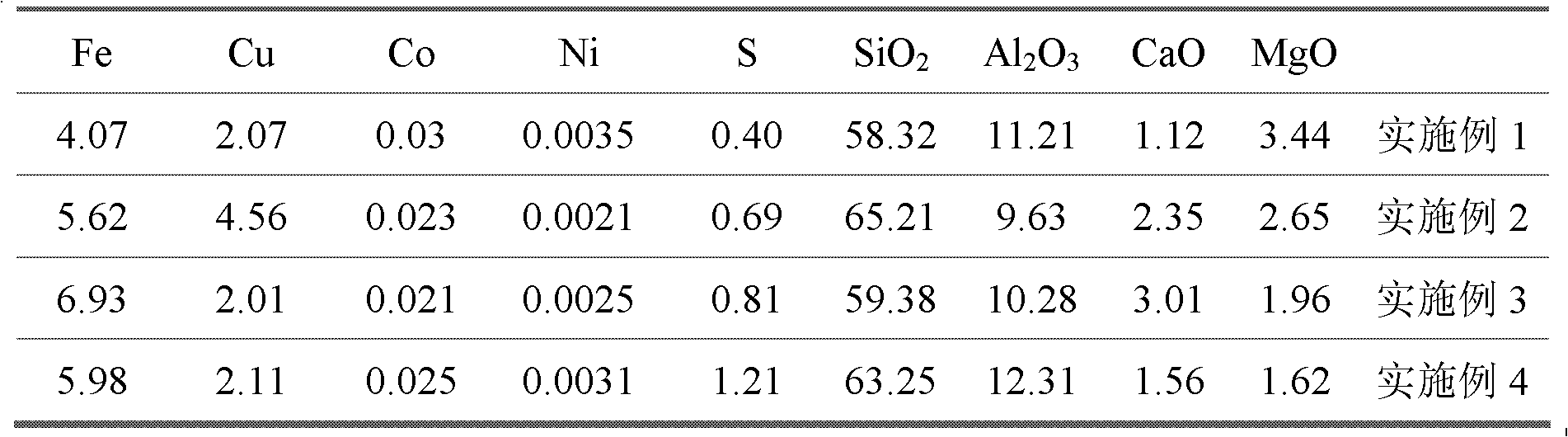

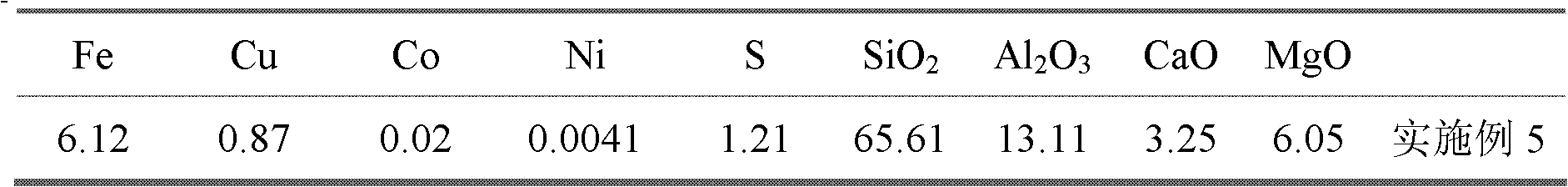

Examples

Embodiment 1

[0096] Lump heap leaching:

[0097] Lay the bottom layer and the anti-seepage layer. The bottom layer is coarse sand with a particle size of 300-400mm. On the anti-seepage layer, the pre-broken copper ore with a thickness of 200-300mm is piled up as a pile. The buffer layer of the field; continue to pile up the crushed +5-40mm copper ore large-grained lump ore in thin layers, each layer is 5-7m high, and lay 4-6 layers; first use a pH value of 0.9- The dilute sulfuric acid solution of 1.2 is pre-sprayed to ensure that the pH value of the leachate is maintained at 1.7-1.9. After the pH value of the leachate is stable for 48 hours, it is 6 cell / mL was inoculated with the above-mentioned ore leaching microorganism combination, intermittent spraying production operation and ventilation were started, and the copper leaching rate was 90.11% after heap leaching for 270 days, and a leaching solution with a copper ion concentration of 2.51g / L was obtained.

[0098] Stirring and leachi...

Embodiment 2

[0102] According to the operation of Example 1, the lump ore was heap leached for 270 days, the copper leaching rate was 94.23%, and the leaching solution with a copper ion concentration of 3.66g / L was obtained.

[0103] According to the operation powder ore bacterial agitation of embodiment 1, the average process index of continuous operation for one month is: the leaching rate of copper is 95.62%, the sulfuric acid consumption is 3.65 tons / ton copper, and the leaching solution that obtains copper ion concentration is 5.78g / L. The two parts of the leaching solution are mixed for extraction-electrodeposition process operation, and the first batch of cathode electrode copper with a purity of 99.995% is obtained.

Embodiment 3

[0105] According to the operation of Example 1, the lump ore was heap leached for 270 days, the copper leaching rate was 90.25%, and the leaching solution with a copper ion concentration of 2.45 g / L was obtained.

[0106] According to the operation powder ore bacterial stirring of embodiment 1, the average process index of continuous operation for one month is: the leaching rate of copper is 92.32%, the sulfuric acid consumption is 3.25 tons / ton copper, and the leaching solution that obtains copper ion concentration is 4.75g / L. The two parts of the leaching solution are mixed with one part to perform the extraction-electrowinning process, and the first batch of cathode electrode copper with a purity of 99.995% is obtained. Part of the leaching solution is obtained through a replacement process to obtain sponge copper with a copper content of 88%.

[0107] The specific process of obtaining sponge copper is as follows, the initial pH value of the leaching solution is adjusted to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com