Manufacture method of LED integrated structure

A manufacturing method and technology of LED chips, which are applied in the manufacturing of printed circuits, components of lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problems of low reliability of chip electrical interconnection, low yield of LED chips, and complex manufacturing processes. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

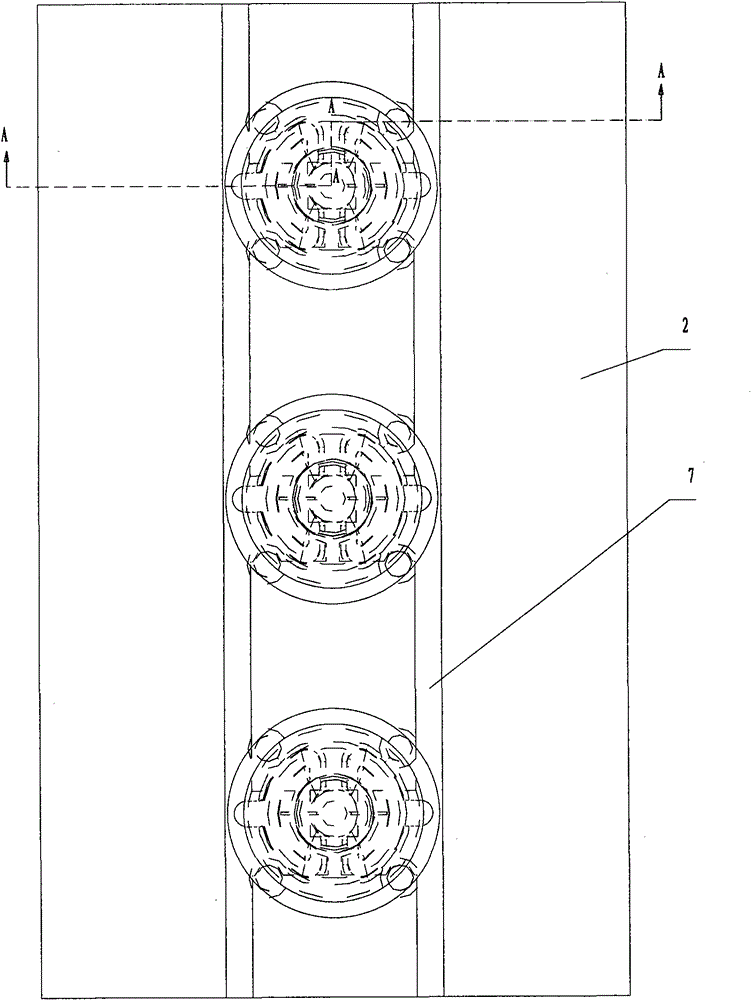

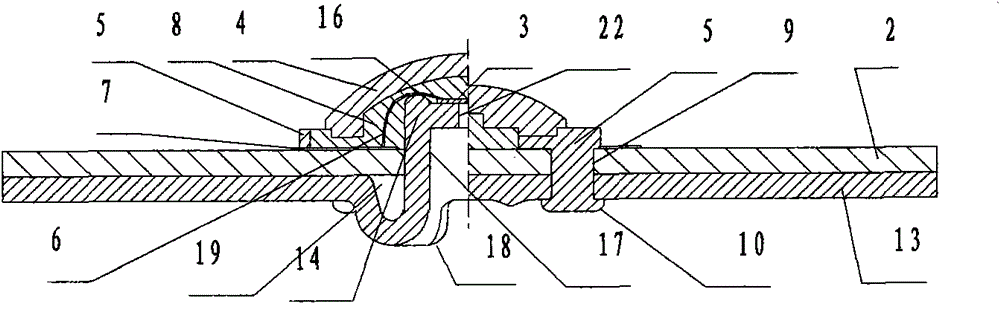

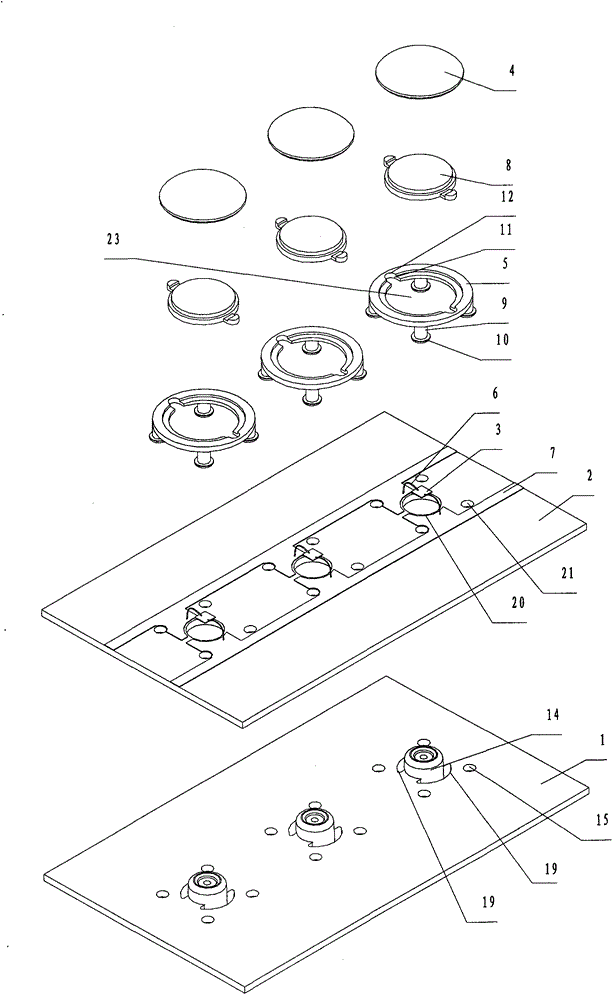

[0094] like Figure 1 to Figure 4 As shown, an LED integrated structure includes a heat dissipation substrate 1, a PCB board 2, an LED chip 3, a lens 4, a lens positioning ring 5, a gold wire 6 electrically connected to an electrode of the LED chip 3, and a layout of the electrically connected gold wire 6 The circuit conductive layer 7 is used for encapsulating the LED chip 3 and the encapsulant 8 of the gold wire 6 . Lens positioning ring 5 selects high-temperature-resistant PPA plastics for use.

[0095] The lens positioning ring 5 is provided with the first through hole 23 for positioning the lens 4 and the encapsulating colloid 8, and the lens positioning ring 5 is extended with a fixed column 9. At the end of the fixed column 9, the heat dissipation substrate 1 is placed on the A resisting portion 10 is formed in the mold for molding the lens positioning ring 5 when molding the plastic positioning ring. The lens positioning ring 5 is provided with a glue injection chann...

Embodiment 2

[0110] like Figure 1 to Figure 4 As shown, different from Embodiment 1, the manufacturing method of the LED integrated structure includes:

[0111] 1) The lens positioning ring 5 is injection-molded, and the fixing column 9, the glue port 12 and the injection channel 11 extending from one end surface of the lens positioning ring 5 are formed at the same time, and the length of the fixing column 9 is longer than the heat dissipation substrate 1 and the PCB board 2 The sum of the thickness;

[0112] 2) On the heat dissipation substrate 1, the chip fixing boss 14 on the heat dissipation substrate 1, the large hole 17 of the heat dissipation step through hole, the heat dissipation rib 18, the heat insulation blind hole 19 in the heat dissipation rib 18, and the lens positioning are formed by stamping The second through hole 15 fitted with the fixing column 9 of the ring 5;

[0113] 3) Small holes 22 connected to the large holes 17 of the heat dissipation step through holes formed...

Embodiment 3

[0124] like Figure 5 As shown, the difference from Embodiment 1 is that an LED integrated structure includes a heat dissipation substrate 50, an LED chip 51, a lens 52, a lens positioning ring 53, a wire 54 electrically connected to an electrode of the LED chip 51, and a wiring for electrically connecting the wire 54. The conductive layer 55 of the circuit shown in the figure is used for encapsulating the LED chip 51 and the encapsulant 56 of the wire 54 . The lens positioning ring 53 selects high temperature resistant PPO+GF plastics, and the number of lens positioning rings is six. There are no heat dissipation ribs and heat insulation blind holes on the heat dissipation substrate 50 .

[0125] The heat dissipation substrate 50 is made of high thermal conductivity ceramics or the like by die-casting. The layout circuit conductive layer 55 is directly disposed on the heat dissipation substrate 50, and the layout circuit conductive layer 55 is distributed on the same plane....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com