Environment-friendly aqueous sealant for container

A container and sealant technology, applied in the field of sealant, can solve the problems of waste of resources and energy, environmental pollution, damage, etc., and achieve the effects of strong adhesion, good physical and mechanical properties, and low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

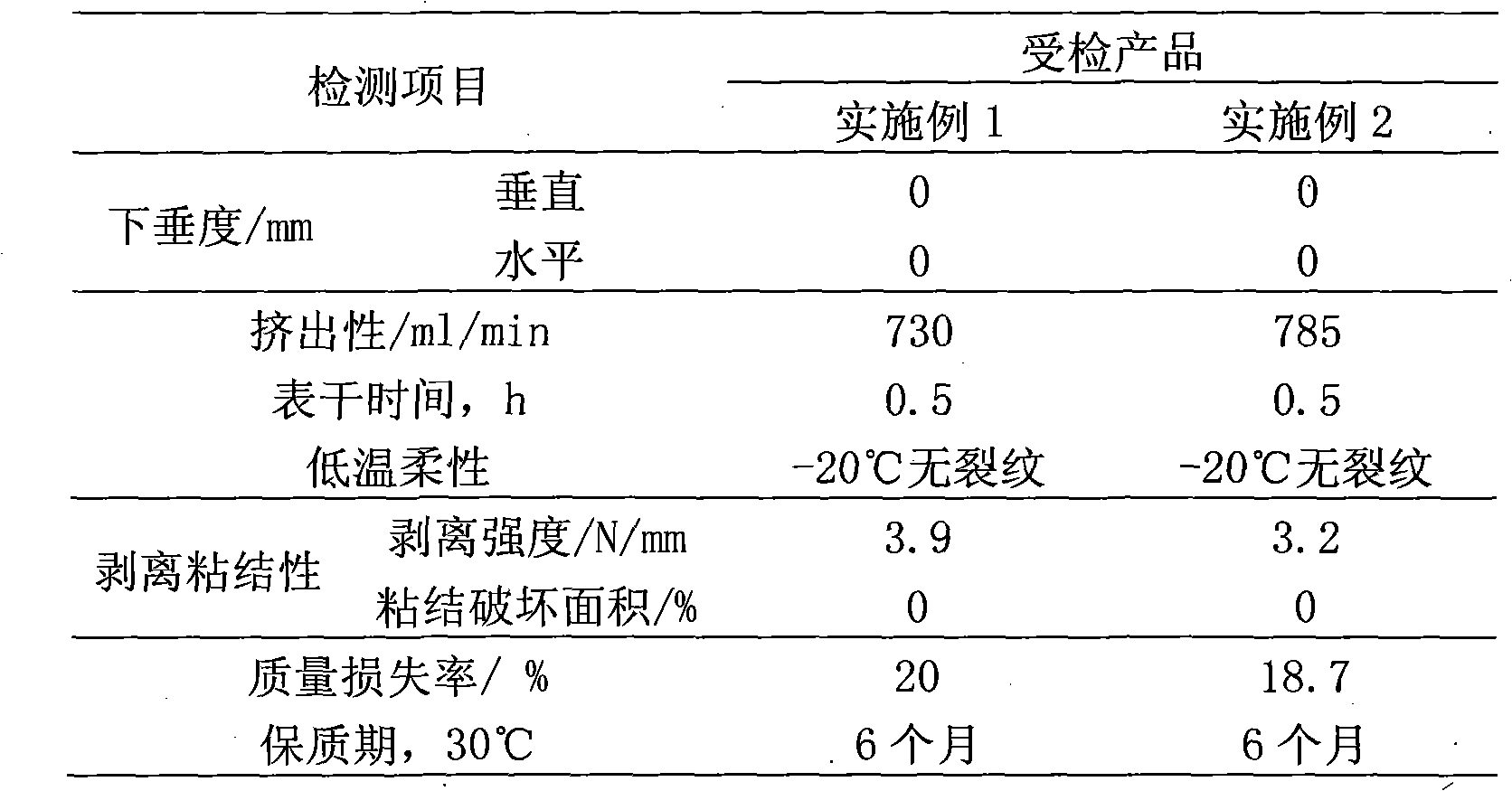

Examples

Embodiment 1

[0027] Environmentally friendly sealant for containers contains:

[0028] 40 parts of emulsion polymer, composed of 35 parts of polyacrylate emulsion and 5 parts of polyvinyl acetate emulsion;

[0029] 0.5 part of dispersant, made up of lauryl alcohol polyoxyethylene ether;

[0030] 5 parts of plasticizer, composed of dioctyl phthalate;

[0031] 1 part of adhesion promoter, consisting of a chelate of bis(dioctyloxypyrophosphate) ethylene titanate and triethanolamine;

[0032] 3.5 parts of thixotropic agent, made up of precipitated silica;

[0033] The filler part is composed of 800 mesh heavy calcium carbonate;

[0034] Antifreeze 0.5 parts, composed of ethylene glycol.

Embodiment 2

[0036] Environmentally friendly sealant for containers contains:

[0037] 40 parts of emulsion polymer, composed of 32 parts of polyacrylate emulsion and 8 parts of polyvinyl acetate emulsion;

[0038] 0.5 part of dispersant, made up of lauryl alcohol polyoxyethylene ether;

[0039] 5 parts of plasticizer, composed of dioctyl phthalate;

[0040] 2 parts of adhesion promoter, consisting of a chelate of bis(dioctyloxypyrophosphate) ethylene titanate and triethanolamine;

[0041] 4.5 parts of thixotropic agent, made up of precipitated silica;

[0042] 60 parts of filler, composed of 50 parts of 800 mesh heavy calcium carbonate and 10 parts of 400 mesh talcum powder;

[0043] Antifreeze 1 part, composed of ethylene glycol.

Embodiment 3

[0045] Environmentally friendly sealant for containers contains:

[0046] 42 parts of emulsion polymer, composed of 32 parts of polyacrylate emulsion and 10 parts of polyvinyl acetate emulsion;

[0047] 0.5 part of dispersant, made up of lauryl alcohol polyoxyethylene ether;

[0048] 5 parts of plasticizer, composed of dioctyl phthalate;

[0049] 2 parts of adhesion promoter, consisting of a chelate of bis(dioctyloxypyrophosphate) ethylene titanate and triethanolamine;

[0050] 5 parts of thixotropic agent, made up of precipitated silica;

[0051] 58 parts of filler, composed of 50 parts of 800 mesh heavy calcium carbonate and 8 parts of 1200 mesh heavy calcium carbonate;

[0052] Antifreeze 1 part, composed of ethylene glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com