Method for preparing dihydro quercetin

A technology of dihydroquercetin and enzymatic hydrolysis, applied in the direction of fermentation, etc., can solve the problems of severe reaction process, expensive raw materials, serious pollution, etc., and achieve the effect of simple operation and few types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

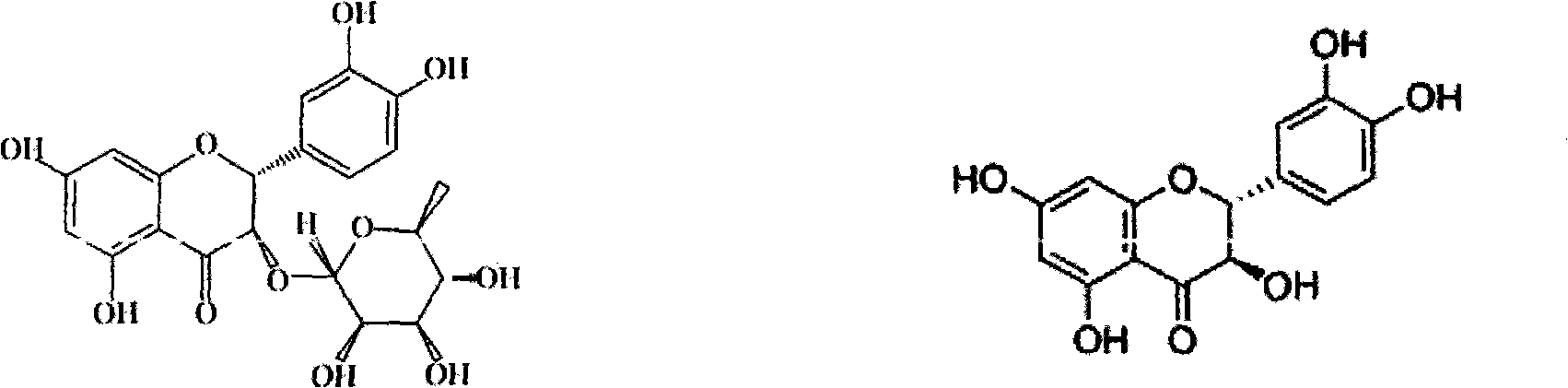

Image

Examples

Embodiment 1

[0037] Remove impurity and crush 20 meshes of Huangqi leaves, take 1kg, add 200ml ph4 hydrochloric acid aqueous solution to moisten, then take 1g of naringinase, add and stir evenly, place it in a thermostat at 35°C for 48 hours, take it out and put it into a flask, add 6L of 90% ethanol to reflux Extract for 1 hour and extract 3 times, extract ethanol by rotary evaporator, add polyamide resin column for adsorption while hot, then use 15BV water→4BV40% ethanol→8BV60% ethanol gradient elution, collect 60% ethanol eluate, reduce The ethanol was recovered under pressure and placed to crystallize, the crystals were filtered out, and then deionized water and 70% ethanol were refluxed to dissolve and recrystallize, the crystals were filtered out and vacuum-dried at low temperature to obtain 32 g of dihydroquercetin with a content of 99%.

Embodiment 2

[0039] Remove impurity and crush 80 meshes of Huangqi leaves, take 1kg, add 100ml ph5 hydrochloric acid aqueous solution to moisten, then take 3g of naringinase and stir evenly, place it in a thermostat at 35°C for 36 hours, take it out and put it into a flask, add 6L of 50% ethanol to reflux Extract for 1 hour and extract 3 times, extract ethanol by rotary evaporator, add polyamide resin column for adsorption while hot, then use 10BV water → 7BV 20% ethanol → 5BV 80% ethanol gradient elution, collect 80% ethanol eluate, reduce The ethanol was recovered under pressure and placed to crystallize, the crystals were filtered out, and then deionized water and 70% ethanol were refluxed to dissolve and recrystallize, the crystals were filtered out and vacuum-dried at low temperature to obtain 37 g of dihydroquercetin with a content of 98%.

Embodiment 3

[0041] Remove impurities and crush 40 meshes of Huangqi leaves, take 1kg, add 150ml of pH5 hydrochloric acid aqueous solution to moisten, then take 5g of naringinase and stir evenly, place it in a thermostat at 35°C for 28 hours, take it out and put it into a flask, add 15L of 70% ethanol to reflux Extract once every 5 hours, extract ethanol by rotary evaporator, add polyamide resin column for adsorption while hot, and then use 13BV water→7BV30% ethanol→6BV75% ethanol for gradient elution, collect 75% ethanol eluate, reduce The ethanol was recovered under pressure and placed to crystallize, the crystals were filtered out, and then deionized water and 70% ethanol were refluxed to dissolve and recrystallize, and the crystals were filtered out and vacuum-dried at low temperature to obtain 36 g of dihydroquercetin with a content of 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com