Quantitative analysis method for measuring trace nickel in water by microwave digestion-flame atomic absorption spectrometry (FAAS)

A technology of microwave digestion and quantitative analysis, which is applied in the preparation of test samples, color/spectral characteristic measurement, etc., can solve the problem of low sensitivity that cannot reach the lower limit of nickel detection, high analysis cost, unfavorable promotion and use, and long analysis time without practical effect and other issues, to achieve the effects of reducing pollution and harm to the human body, saving measurement costs, and low instrument maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Determination of nickel content and recovery rate experiment in environmental engineering laboratory wastewater of Shenyang University of Technology:

[0082] (1) Microwave digestion pretreatment of samples: accurately pipette 5.0ml water samples from three waste liquid buckets into microwave digestion tanks (take 3 copies of each sample for parallel test, and take 3 copies for recovery rate experiment at the same time), Add 10.0ml of 70.0% nitric acid, 1.0ml of 40.0% hydrofluoric acid and 1.0ml of 30.0% hydrogen peroxide, cover the lid, insert it into the protective cover, and put a burst membrane on it. At the same time, prepare a blank solution, and then put it into the microwave digestion apparatus Sample digestion. Digestion pressure 2.5MPa, digestion time 15min. After the digestion program is over, when the temperature reaches 40°C, turn on the microwave digestion apparatus and take out the digestion tank; transfer the sample in the digestion tank to a beaker, he...

Embodiment 2

[0092] Determination of nickel content and recovery rate experiment in Taizi River water of Liaoyang City:

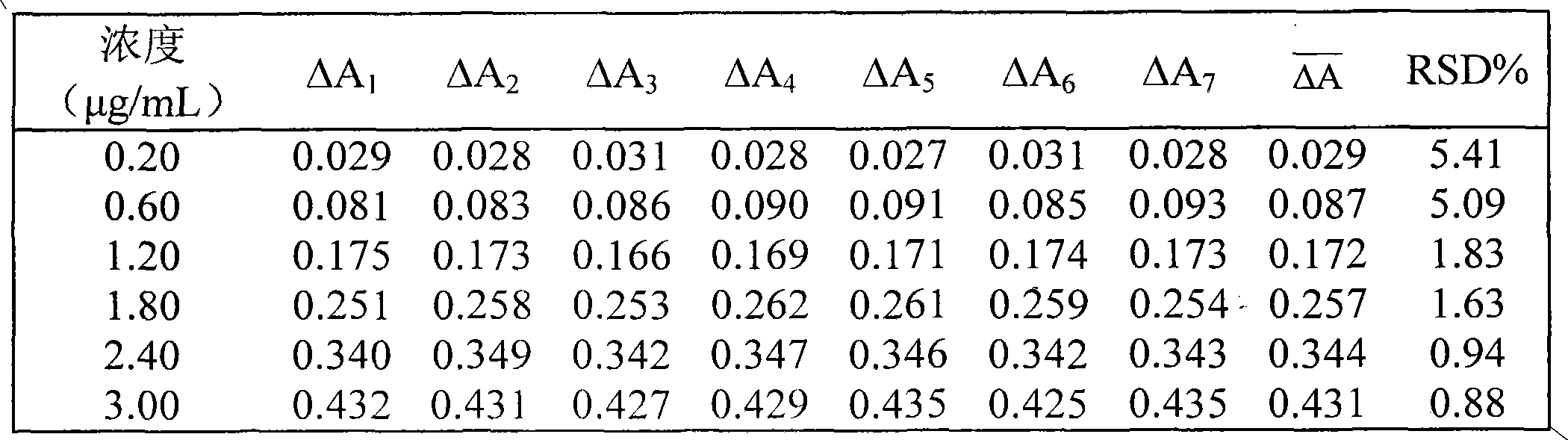

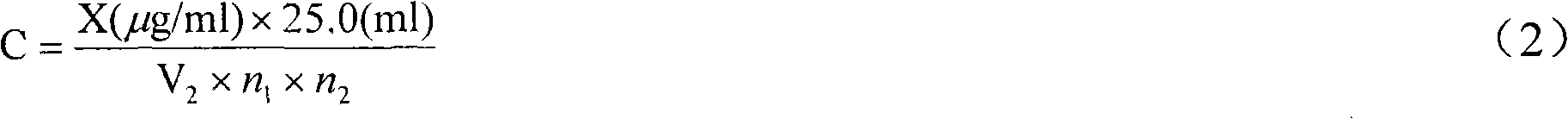

[0093] (1) Sample concentration and microwave digestion pretreatment: Accurately remove the detected leaves and debris and filter them through a filter membrane with a pore size of 0.45 μm to remove suspended particles in Taizi River in March, May, and July 2010. 2000.0ml in a 2000ml beaker (take 3 parts of each sample for parallel experiments, and take 3 parts at the same place for recovery experiment), evaporate and concentrate to 10.0ml (n 1 =200). Take 10 digestion tanks, add 5.0ml of concentrated water sample to 9 digestion tanks, add 10.0ml of 70.0% nitric acid, 1.0ml of 40.0% hydrofluoric acid and 1.0ml of 30.0% hydrogen peroxide, cover the lids and insert the protective cover In, and put the burst membrane, while preparing a blank solution. Then put it into a microwave digestion apparatus for sample digestion. The digestion pressure is 2.5MPa, and the digesti...

Embodiment 3

[0102] Determination of nickel content and recovery rate in coal washing water of a coal washing plant in Dengta City

[0103] (1) Sample microwave digestion pretreatment: Accurately pipette 5.0ml of water samples of coal washing water in the morning, middle and evening shifts of three shifts in May, filtered through a filter membrane with a 0.45 μm pore size to remove particles suspended in the water (3 Add 10.0ml of 70.0% nitric acid, 1.0ml of 40.0% hydrofluoric acid and 1.0ml of 30.0% hydrogen peroxide to the digestion tank, cover the lid, insert it into the protective cover, and put the burst membrane on it, and prepare a blank solution at the same time . Then put it into a microwave digestion apparatus for sample digestion, the digestion pressure is 2.5MPa, and the digestion time is 30min. After the digestion program is finished, when the temperature display reaches 38°C, turn on the microwave digestion apparatus, take out the digestion tank and transfer the sample to a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slit width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com