Method for preparing split-phase coloring iron black glaze

A technology of iron black and phase separation, which is applied in the field of preparation of high, medium and low temperature ceramic black glazes, can solve the problems of large pollution, non-compliance, high energy consumption, etc., and achieve the effect of improving color stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] 1) Preparation of boron frit: by mass percentage, 45.5% feldspar, 15.2% quartz, 7.6% calcite, 22.7% boric acid, 4.5% NaNO 3 , 4.5% Li 2 CO 3 Grind the mixture evenly in a mortar, put the mixture into a crucible calcined to 1260°C in a high-temperature furnace, melt it for 10 minutes, and quench water to obtain a boron frit;

[0012] 2) Preparation of glaze slurry: by mass percentage, 44% feldspar, 18% quartz, 4% Suzhou soil, 4% calcite, 14% talc, 4% ZnO, 2% calcium phosphate, 2% % Boron frit, 5% Fe 2 o 3 , 1% of cellulose, 1% of sodium tripolyphosphate and 1% of CMC are mixed, finely ground to 250 mesh, and the specific gravity of the prepared glaze slurry is 1.7g / cm 3 ;

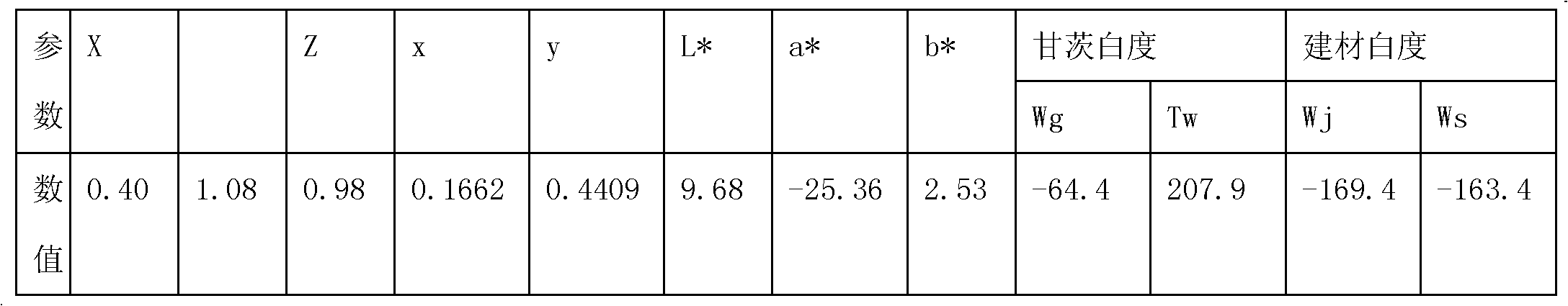

[0013] 3) Apply the glaze slurry evenly on the base, raise the temperature to 1190°C, keep it warm for 40 minutes, and then cool naturally to obtain the phase-separated colored iron black glaze (the parameters of the specific test results of the samples are shown in Table 1).

[0014]

Embodiment 2

[0016] 1) Preparation of boron frit: by mass percentage, 45.5% feldspar, 15.2% quartz, 7.6% calcite, 22.7% boric acid, 4.5% NaNO 3 , 4.5% Li 2 CO 3 Grind the mixture evenly in a mortar, put the mixture into a crucible calcined to 1260°C in a high-temperature furnace, melt it for 10 minutes, and quench water to obtain a boron frit;

[0017] 2) Preparation of glaze slurry: by mass percentage, 40% feldspar, 30% quartz, 3% Suzhou soil, 3% calcite, 5% talc, 2% ZnO, 8% calcium phosphate, 1 % Boron frit, 5% Fe 2 o 3 , 1% cellulose, 1% sodium tripolyphosphate and 1% CMC mixed, finely ground to 250 mesh, the specific gravity of the prepared glaze slurry is 1.6g / cm 3 ;

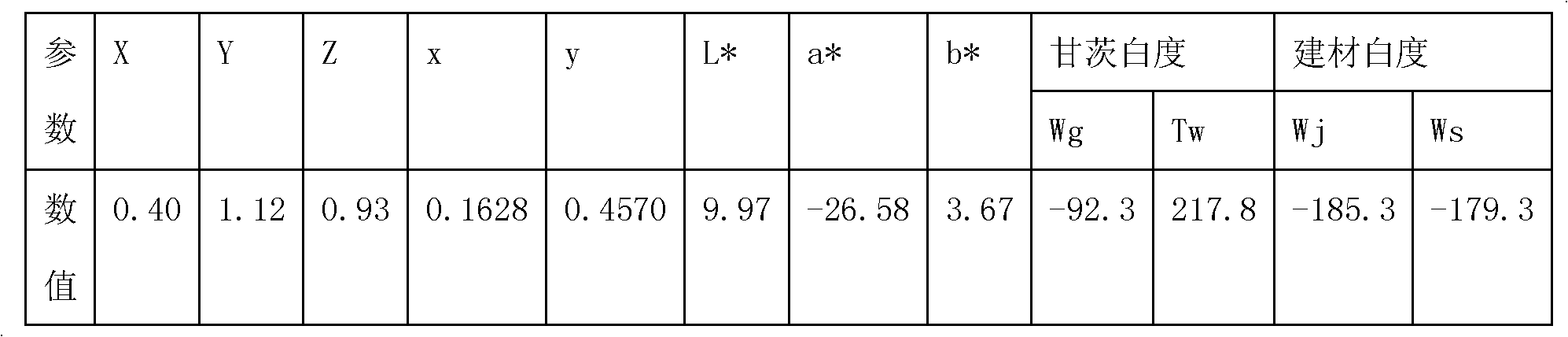

[0018] 3) Apply the glaze slurry evenly on the base, raise the temperature to 1210°C, keep it warm for 25 minutes, and then cool naturally to obtain the phase-separated colored iron black glaze (the parameters of the specific test results of the samples are shown in Table 2).

[0019]

Embodiment 3

[0021] 1) Preparation of boron frit: by mass percentage, 45.5% feldspar, 15.2% quartz, 7.6% calcite, 22.7% boric acid, 4.5% NaNO 3 , 4.5% Li 2 CO 3 Grind the mixture evenly in a mortar, put the mixture into a crucible calcined to 1260°C in a high-temperature furnace, melt it for 10 minutes, and quench water to obtain a boron frit;

[0022] 2) Preparation of glaze slurry: 55% feldspar, 15% quartz, 5% Suzhou soil, 5% calcite, 8% talc, 1% ZnO, 1% calcium phosphate, 2% by mass percentage % Boron frit, 5% Fe 2 o 3 , 1% of cellulose, 1% of sodium tripolyphosphate and 1% of CMC are mixed, finely ground to 250 mesh, and the specific gravity of the prepared glaze slurry is 1.7g / cm 3 ;

[0023] 3) Apply the glaze slurry evenly on the base, raise the temperature to 1180°C, keep it warm for 45 minutes, and then cool naturally to obtain the phase-separated colored iron black glaze.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com