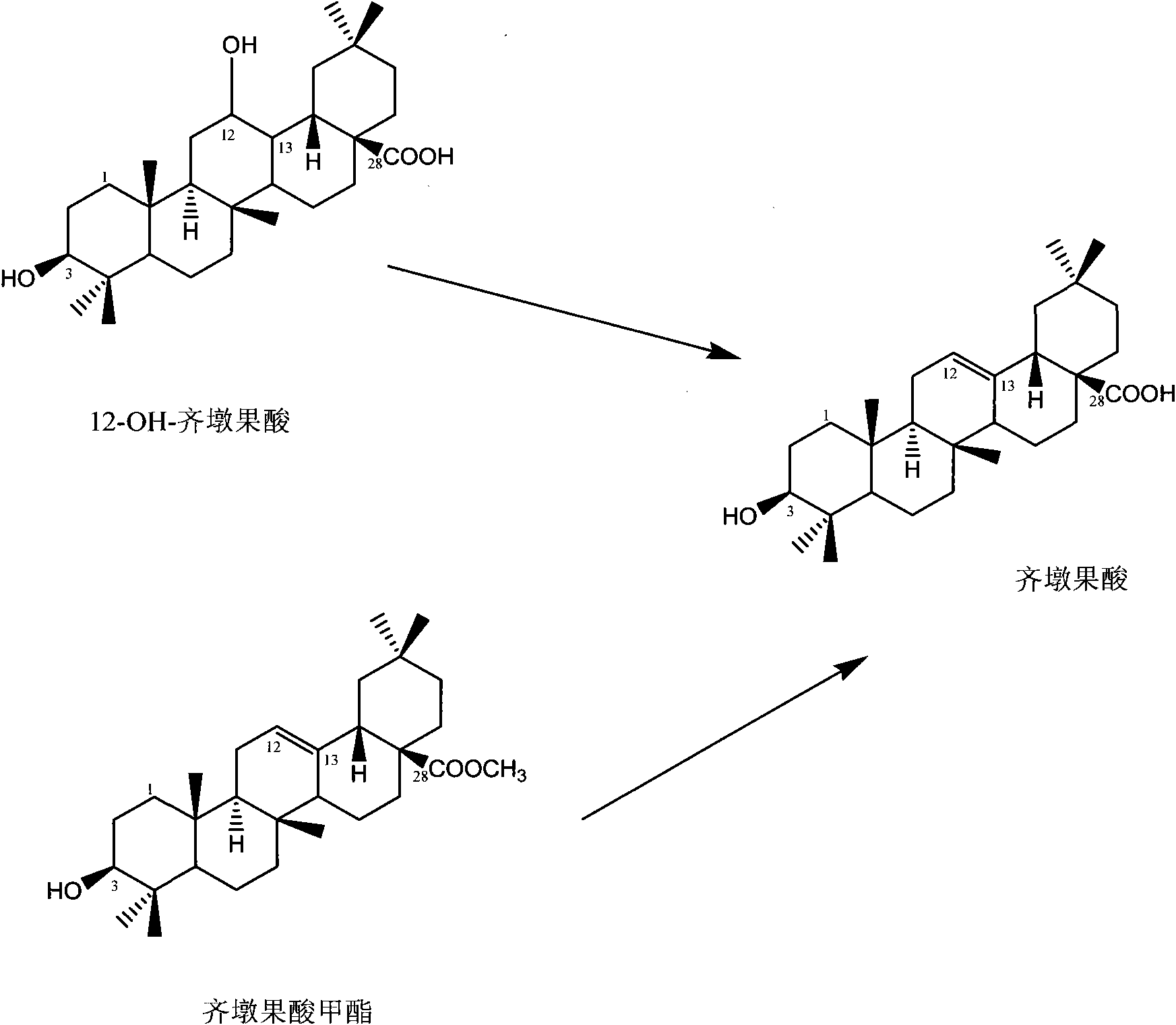

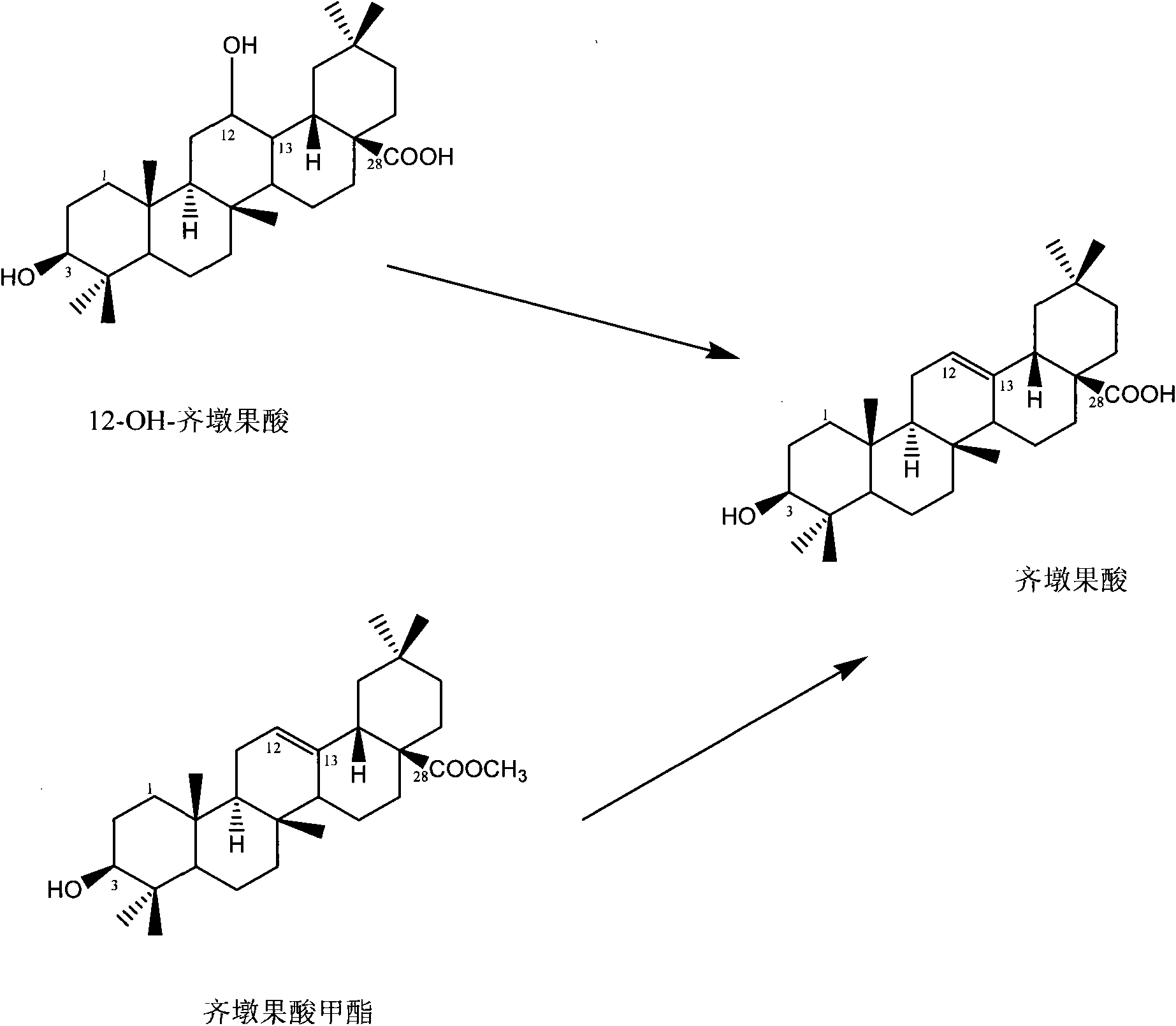

Preparation of oleanolic acid structure analogues and semisynthesis method of oleanolic acid

A technology with oleanolic acid and similar structure, which is applied in the field of chemical substances or pharmaceutical manufacturing, can solve problems such as low efficiency and low extraction yield, and achieves the effects of solving low efficiency, simple method and low extraction yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Raw material pretreatment steps:

[0028] Take Oleaceae plant olean fruit (olea europaea l.) leaves as raw material, dry, pulverize and sieve, accurately weigh 1000g, add 500ml of aqueous solution containing 0.50g of cellulase and 0.50g of pectinase, wherein the volume of the aqueous solution The mass ratio with raw material is 0.5: 1 (volume mass ratio), the mass ratio of the amount of cellulase and raw material is 0.5: 1000 (mass ratio), the mass ratio of the quality of pectinase and raw material is 0.5: 1000 (mass ratio) ratio), heated to 60°C, reacted for 1 hour, and dried to obtain the extracted raw material.

[0029] (2) Extraction step

[0030] With the extraction raw material gained in step (1), extract with 80% ethanol, extract under 60 ℃, solid-liquid ratio 1: 10, extract three times, combine extraction solution and add up to 30L, add 300g chitosan precipitation, the quality of chitosan addition The volume ratio to the extract was 1:100 (mass volume ratio)...

Embodiment 2

[0039] (1) Raw material pretreatment steps:

[0040] Take privet (ligustrum lucidum ait.) fruit raw material, dry, pulverize and sieve, accurately weigh 2000g, add 4000ml of aqueous solution containing 6.0g of cellulase and 4.0g of pectinase, wherein the volume of the aqueous solution and the mass ratio of the raw material Be 2: 1 (volume mass ratio), the mass ratio of the amount of cellulase and raw material is 3: 1000 (mass ratio), the mass ratio of the quality of pectinase and raw material is 2: 1000 (mass ratio), be heated to After reacting at 30° C. for 3 hours, it was dried to obtain the raw material for extraction.

[0041] (2) Extraction step

[0042] With the extraction raw material gained in the step (1), extract with 50% ethanol, extract under 90 ℃, solid-liquid ratio 1: 5, extract three times, combine extracting solution and add up to 30L, add 900g chitosan precipitation, the quality of chitosan adding The volume ratio to the extract was 3:100 (mass volume ratio)...

Embodiment 3

[0051] (1) Raw material pretreatment steps:

[0052] Get the Lycoris raw material, after drying, pulverizing and sieving, accurately weigh 3000g, add 3000ml of aqueous solution containing 3.0g of cellulase and 3.0g of pectinase, wherein the volume of the aqueous solution and the mass ratio of Lycoris raw material are 1: 1 (volume mass ratio), the mass ratio of the amount of cellulase to Lycoris raw material is 1: 1000 (mass ratio), the mass ratio of the quality of pectinase to Lycoris is 1: 1000 (mass ratio), heated to 50°C, After reacting for 2 hours, it was dried to obtain the raw material for supercritical extraction.

[0053] (2) Extraction step

[0054] With the extraction raw material gained in the step (1), extract with 60% ethanol, extract under 80 ℃, solid-liquid ratio 1: 8, extract three times, combine extracting solution to add up to 72L, add 1440g chitosan precipitation, the quality of chitosan adding The volume ratio to the extract was 2:100 (mass volume ratio),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com