Method for extracting ovalbumin peptide

A technology of ovalbumin and extraction method, which is applied in the direction of peptide preparation method, chemical equipment and method, peptide, etc., can solve the problems of not using membrane separation technology, reducing the economic benefit of the enterprise, destroying protein components, etc., and increasing the stomach Intestinal function burden, no toxic side effects, short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for extracting ovalbumin peptides, the steps of which are as follows:

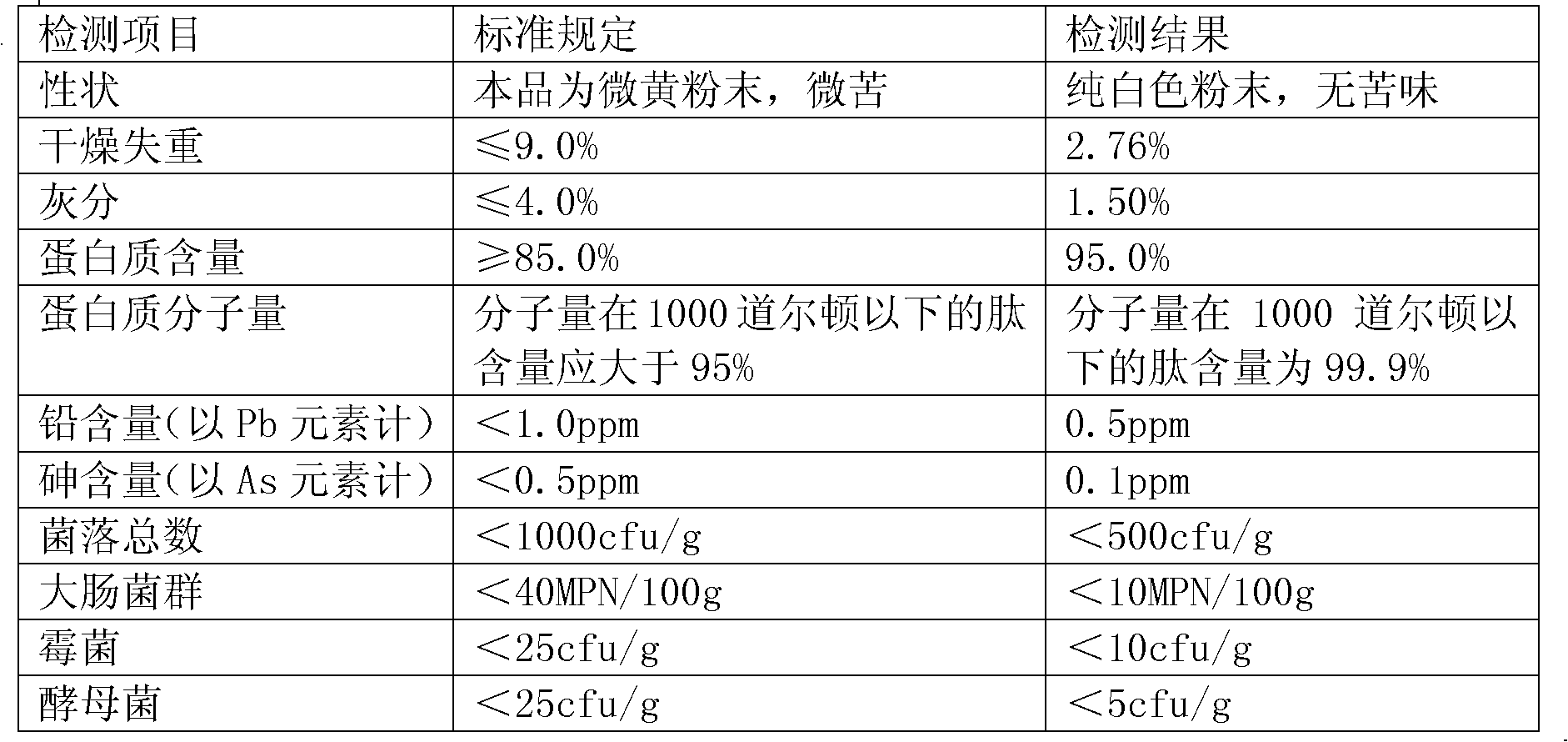

[0025] Weigh 1kg of egg protein, mash it, add 5kg of pure water, stir evenly, raise the temperature to 52°C, adjust the pH to 7.5 with food-grade flake sodium hydroxide, add 10g of Bacillus subtilis alkaline protease, stir at 52°C for enzymatic hydrolysis 4h, use food-grade sodium hydroxide flakes to keep the pH value stable during the enzymolysis process; then add 5g flavored protease, add food-grade flake sodium hydroxide to adjust the pH value to 8.0, stir at 52°C for 5 hours, enzymolysis During the process, use food-grade flake sodium hydroxide to keep the pH value stable; then raise the temperature to 92°C and keep it warm for 11 minutes to inactivate the enzyme; filter the enzymatic solution to obtain a supernatant; add 22g of powdered activated carbon to the supernatant, and stir at 45°C Adsorption 1h decolorizes, and filters out gac; Filtrate is filtered with the filter machine of 1...

Embodiment 2

[0029] A method for extracting ovalbumin peptides, the steps of which are as follows:

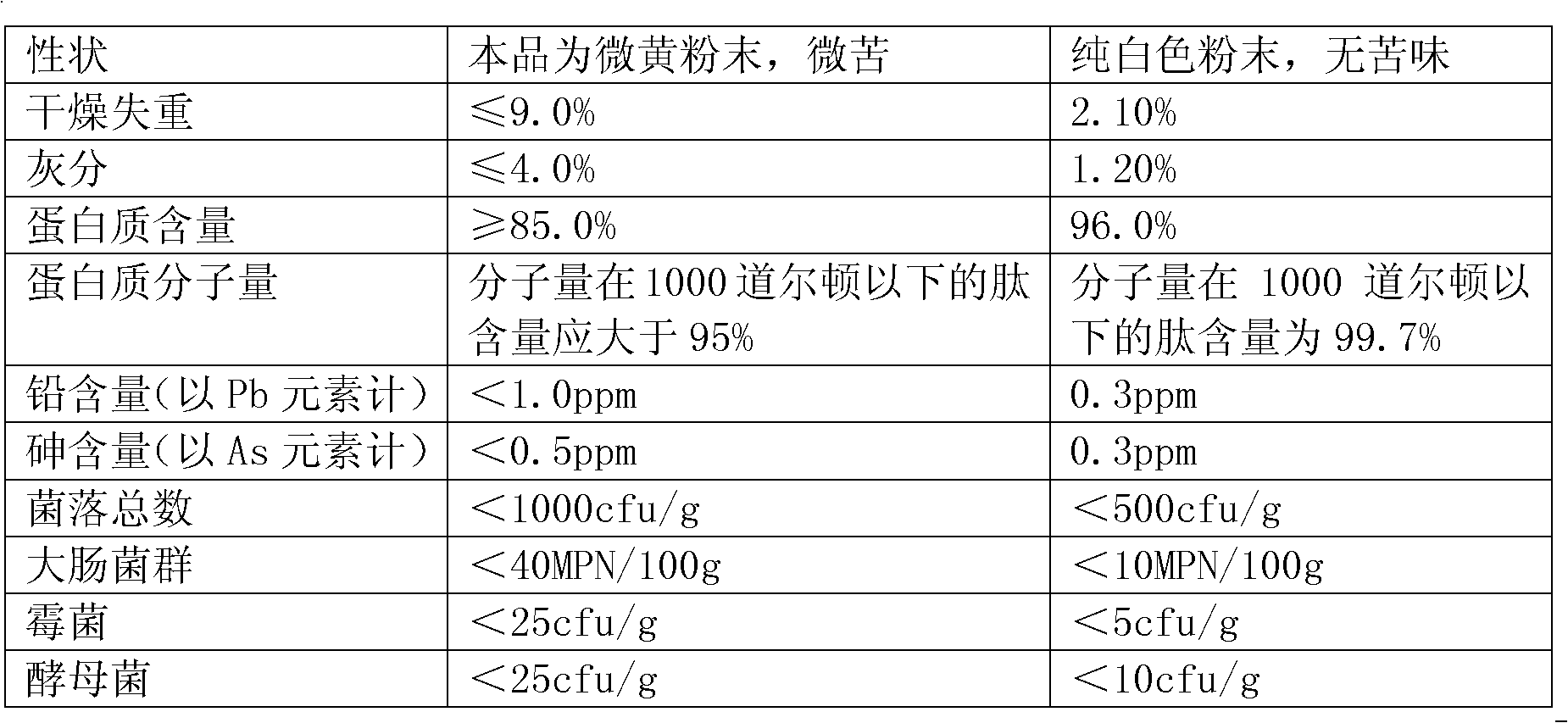

[0030] Weigh 2kg of egg protein, mash it, add 10kg of pure water, stir evenly, raise the temperature to 57°C, adjust the pH to 8 with food-grade flake sodium hydroxide, add 20g of Bacillus subtilis alkaline protease, stir at 57°C for enzymolysis 5h, during the enzymolysis process, use food-grade flake sodium hydroxide to keep the pH value stable; then add 10g of flavored protease, add food-grade flake sodium hydroxide to adjust the pH value to 8.2, stir at 57°C for 6h, enzymolysis process Use food-grade flake sodium hydroxide to keep the pH value stable; then raise the temperature to 93°C and keep it warm for 11 minutes to inactivate the enzyme; filter the enzymatic solution to obtain a supernatant; add 40g of powdered activated carbon to the supernatant, stir and adsorb at 44°C Decolorize for 1.2 hours, filter out activated carbon; filter the filtrate with a filter with a membrane pore siz...

Embodiment 3

[0035] A method for extracting ovalbumin peptides, the steps of which are as follows:

[0036] Weigh 10kg of egg whites, mash them, add 50kg of pure water, stir evenly, raise the temperature to 54°C, adjust the pH to 8.2 with food-grade flake sodium hydroxide, add 100g of Bacillus subtilis alkaline protease, stir at 54°C for enzymolysis 5.5h, during the enzymolysis process, use food-grade flake sodium hydroxide to keep the pH value stable; then add 50g of flavored protease, add food-grade flake sodium hydroxide to adjust the pH value to 8.3, stir at 54°C for 6.5h, enzymatic hydrolysis During the hydrolysis process, food-grade flake sodium hydroxide was used to keep the pH value stable; then the temperature was raised to 94°C and kept for 10 minutes to inactivate the enzyme; the enzymolysis solution was filtered to obtain a supernatant; Stir and adsorb for 1.5 hours to decolorize, filter out activated carbon; filter the filtrate with a filter with a membrane pore size of 1 nm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com