Method for preparing quantum dot film in a water phase through electrophoretic deposition

An electrophoretic deposition and quantum dot technology, applied in the field of nanomaterials, can solve problems such as unfavorable large-scale production process, waste of energy, pollution of the environment, etc., and achieve the effects of low voltage, energy saving, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

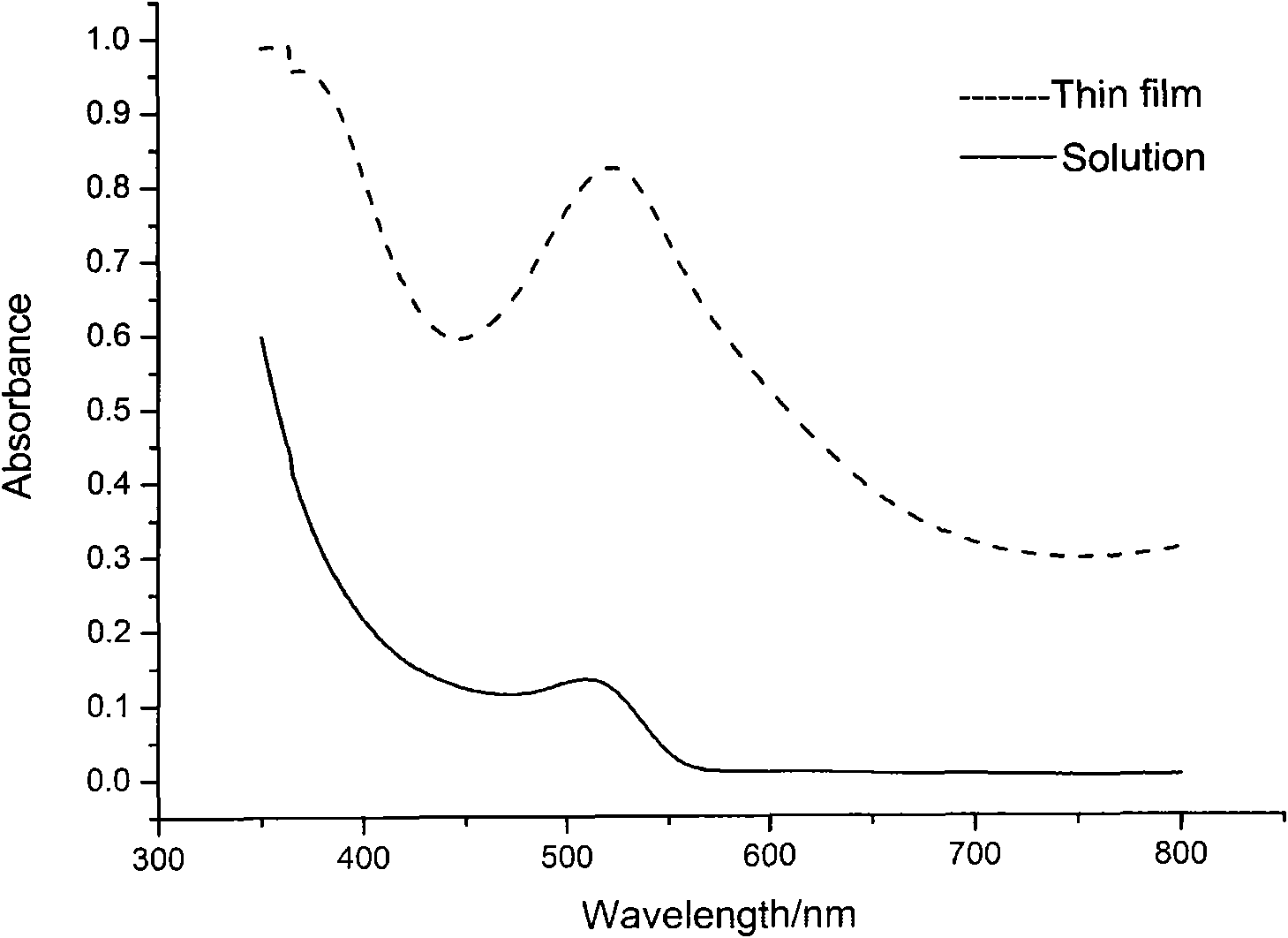

Embodiment 1

[0021] (1) After cleaning the indium tin oxide (ITO) conductive glass with detergent, put it into a mixed solution of acetone and ethanol with a volume ratio of 1:1, ultrasonic for 15 minutes, rinse it with clean water, and dry it; then placed in V(H 2 O): V(H 2 o 2 ): V(NH 3 )=5:1:1 mixed solution, heated in a water bath at 60°C for 1h to carry out hydroxylation on the surface; finally put 0.5M chlorine of 1mg / ml polydiallyldimethylammonium chloride (PDDA) Soak in sodium chloride solution for 15 minutes to enrich a layer of positive charges on the surface, then rinse it with deionized water and dry it; in addition, clean a piece of zinc sheet with the same size as ITO conductive glass with deionized water and dry it.

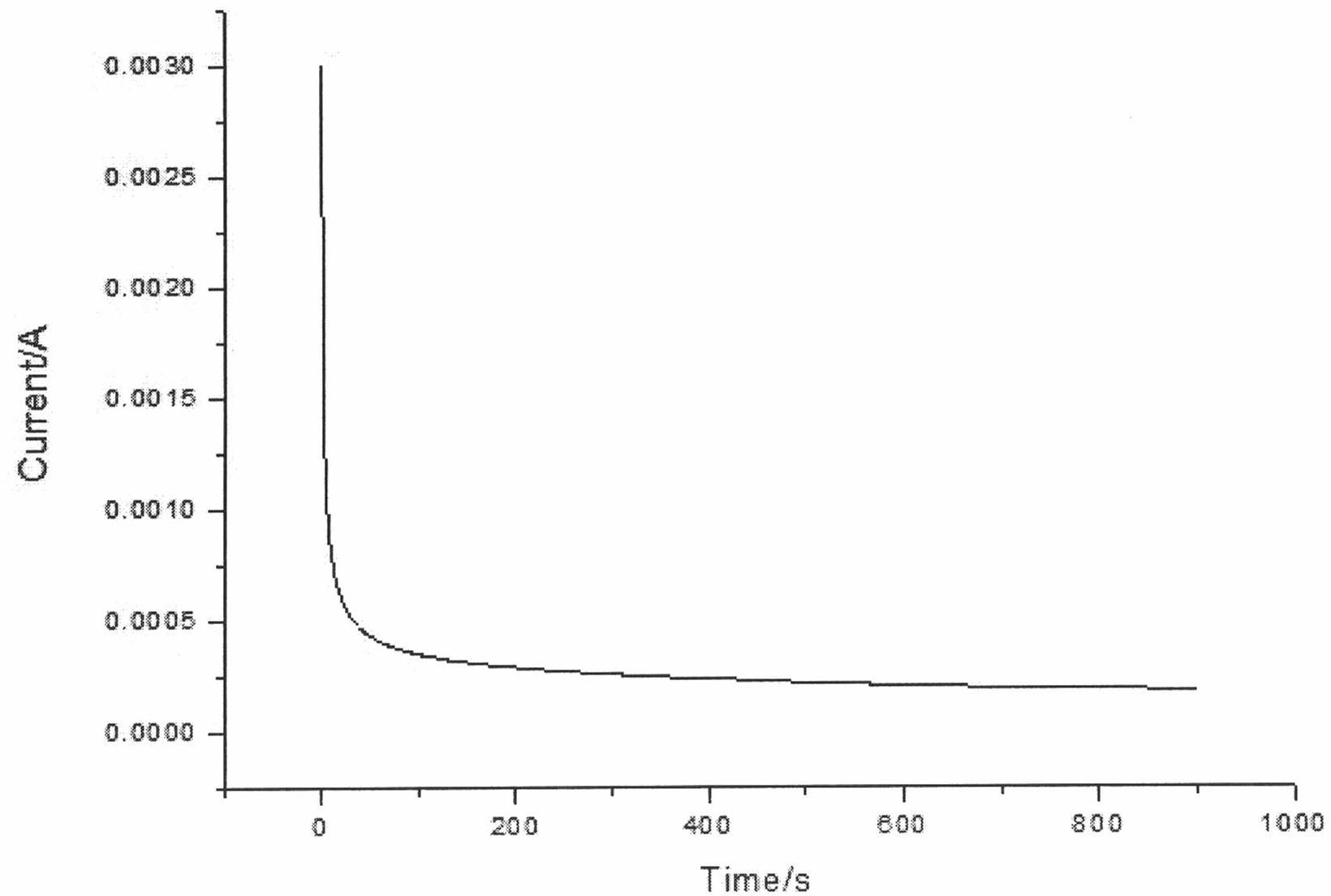

[0022] (2) Take 2.5ml of CdTe (TGA-CdTe) quantum dot hydrosol modified with negatively charged thioglycolic acid (TGA) on the surface, add 0.5ml of 5mg / ml ascorbic acid aqueous solution, and adjust its pH value to 7.8 with 0.1M NaOH.

[0023] (3) Pass argon...

Embodiment 2

[0027] (1) The surface treatment process of the ITO conductive glass is the same as in Example 1. In addition, an aluminum sheet with the same size as the ITO conductive glass was cleaned with deionized water and dried.

[0028] (2) Take 2.5ml of TGA-CdTe quantum dot hydrosol with negative charge on the surface, add 0.15ml of 0.5M hydroquinone aqueous solution, and adjust its pH value to 9.0 with 0.1M NaOH.

[0029] (3) Pass argon gas in the above solution for 30 minutes to fully remove oxygen, and immerse the cleaned ITO conductive glass and the aluminum sheet in the solution with the conductive surface parallel to each other. The distance between the ITO conductive glass and the aluminum sheet is 2mm.

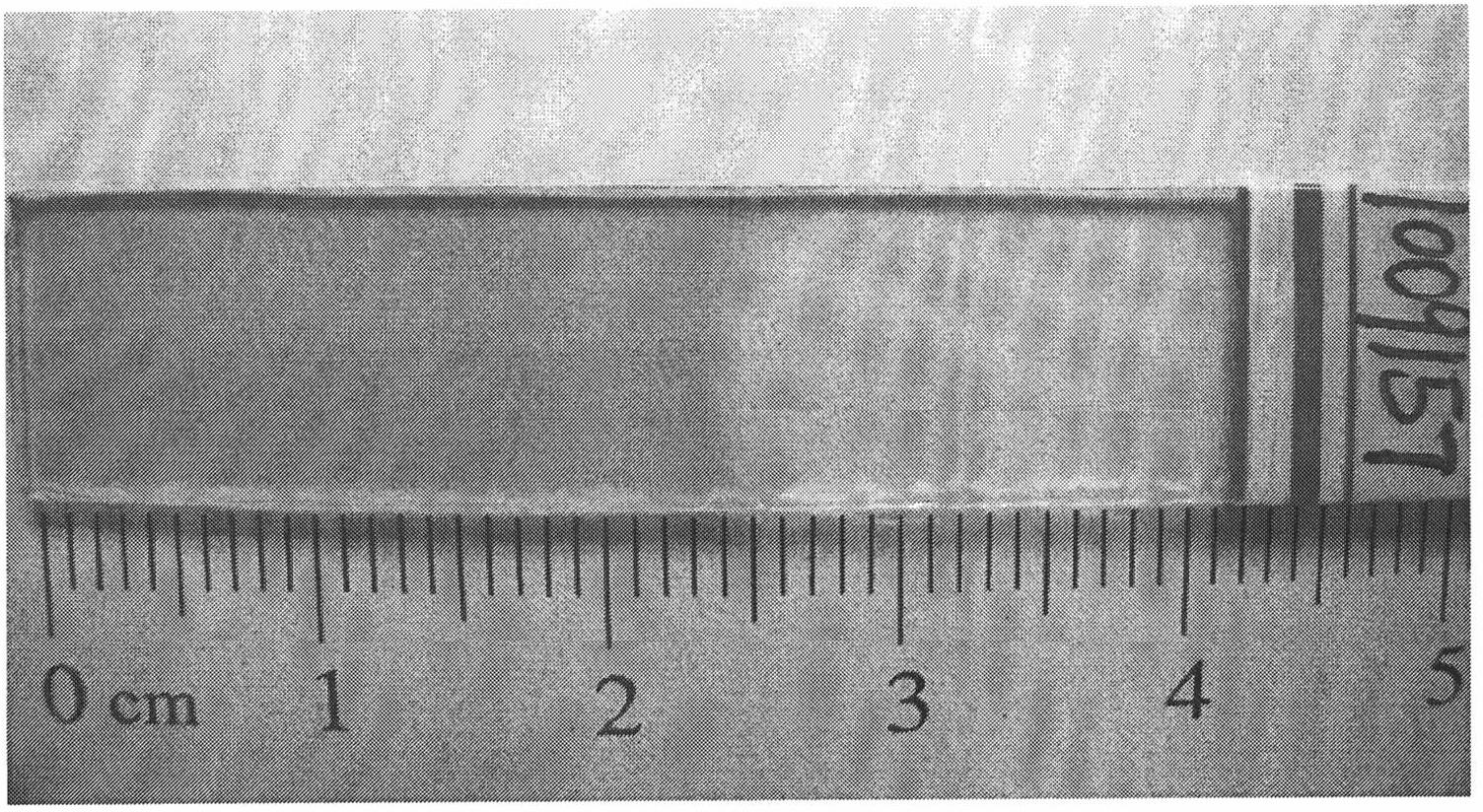

[0030] (4) Connect the ITO conductive glass to the positive pole of a DC power supply, connect the aluminum sheet to the negative pole of the power supply, set the voltage to 2.5V, and set the deposition time to 15 minutes, then a uniform smooth TGA- CdTe quantum dot film. ...

Embodiment 3

[0033] (1) The surface treatment process of the ITO conductive glass is the same as in Example 1. In addition, a stainless steel sheet with the same size as the ITO conductive glass was cleaned with deionized water and dried.

[0034] (2) Take 2.5ml of TGA-CdTe quantum dot hydrosol with negative charge on the surface, add 0.15ml of 0.5M sodium sulfide aqueous solution, and adjust the pH value to 10.5 with 0.1M NaOH.

[0035] (3) Pass argon gas in the above solution for 30 minutes to fully remove oxygen, and immerse the cleaned ITO conductive glass and stainless steel sheet in the solution with the conductive surface parallel to each other. The distance between the ITO conductive glass and the stainless steel sheet is 2mm.

[0036] (4) Connect the ITO conductive glass to the positive pole of a DC power supply, connect the stainless steel sheet to the negative pole of the power supply, set the voltage to 2.2V, and set the deposition time to 25min, then a uniform TGA- with smooth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com