Molybdenum disulfide nanosphere/titanium dioxide composite material and preparation method thereof

A technology of titanium dioxide and molybdenum disulfide, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as environmental pollution, poor chemical stability, and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

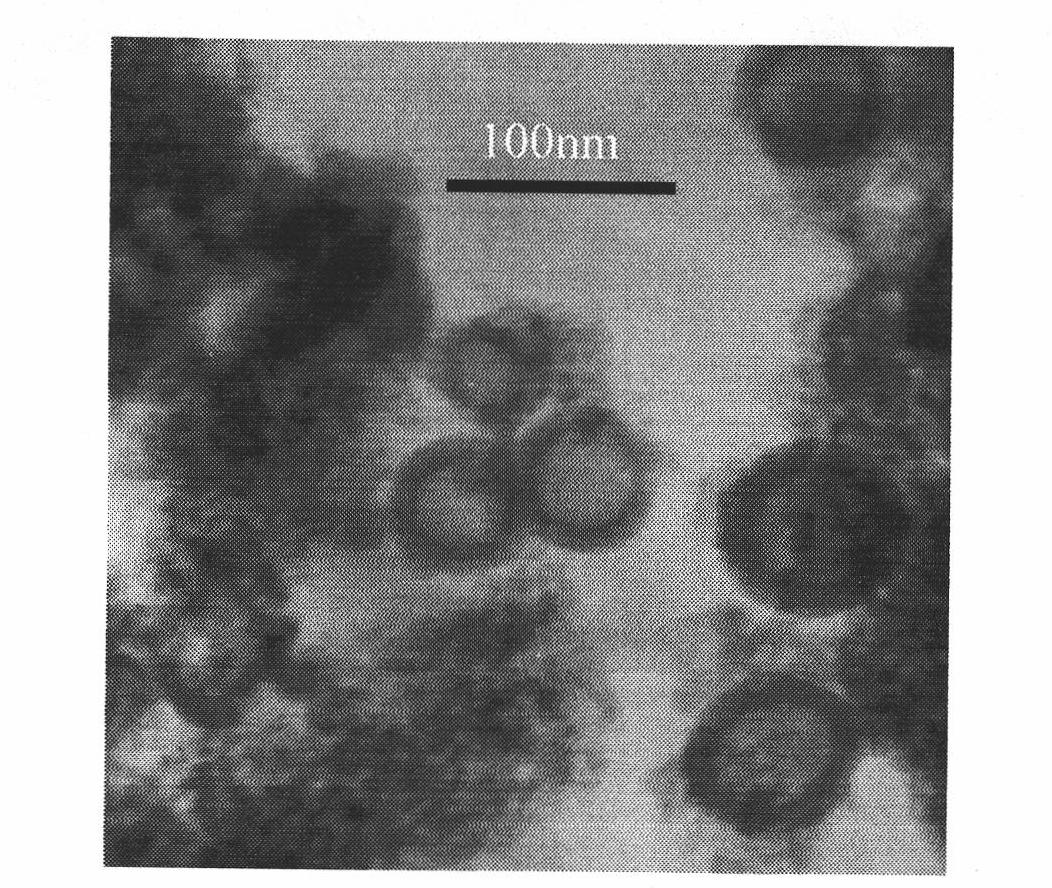

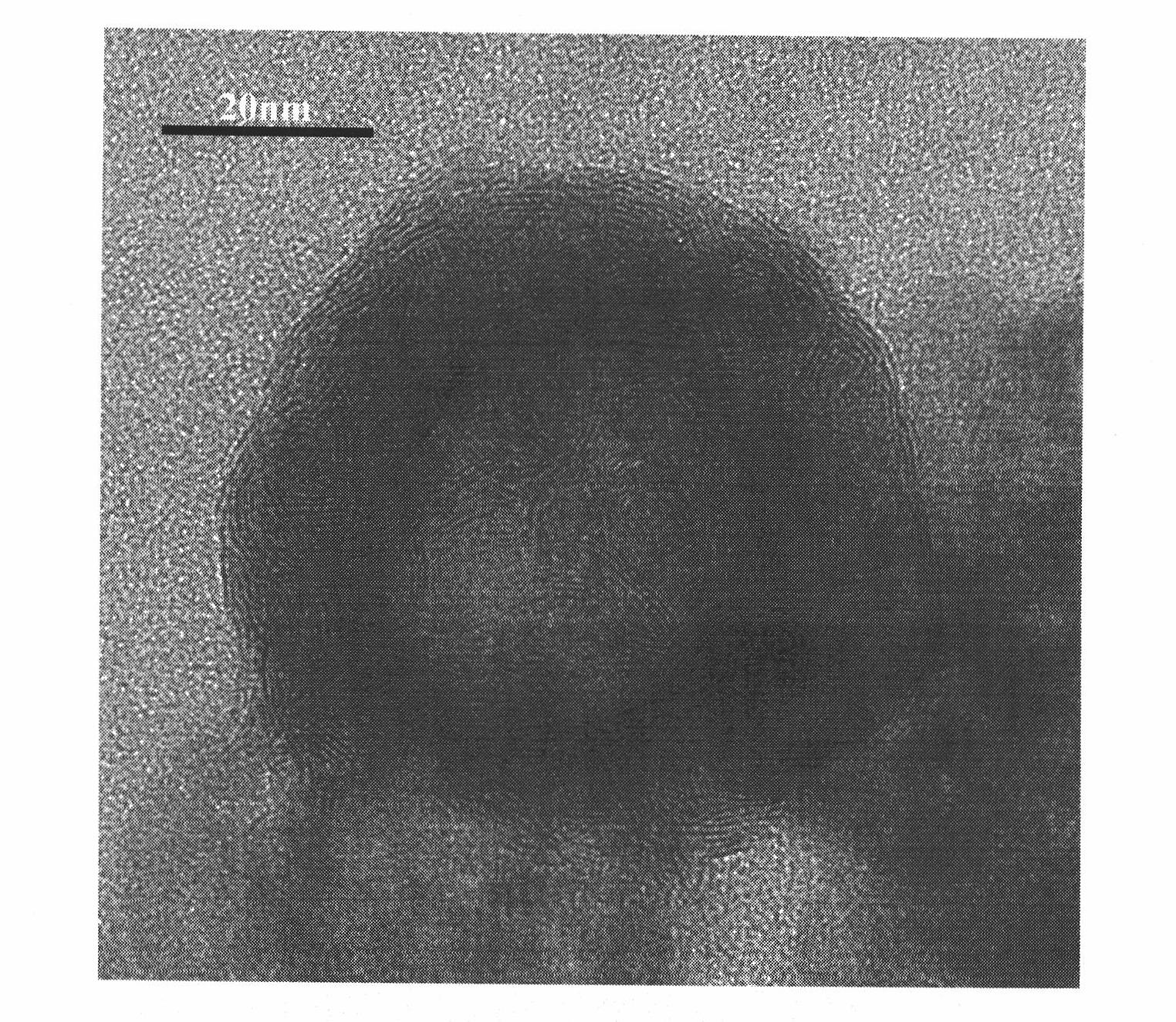

Image

Examples

Embodiment 1

[0010] Take 1 part of titanium dioxide, 100 parts of sodium molybdate and 100 parts of thioacetamide, and add 2000 parts of distilled water. When the above system was heated and stirred to 60°C, the pH value was adjusted to 0.5 with hydrochloric acid, stirred for 9 minutes, filtered, washed and dried, and the solid product was calcined in hydrogen at 400°C for 50 minutes, cooled to room temperature, and the sample was obtained. Molybdenum disulfide nanospheres / titanium dioxide composites.

Embodiment 2

[0012] Take 10 parts of titanium dioxide, 1 part of ammonium molybdate and 20 parts of thioacetamide, and add 1000 parts of distilled water. When heating and stirring the above system to 100°C, adjust the pH value to 1 with phosphoric acid, stir and react for 20 minutes, filter, wash and dry the solid product in N 2 Calcined at 800°C for 60 minutes, cooled to room temperature, and took out the sample to obtain the molybdenum disulfide nanosphere / titanium dioxide composite material.

Embodiment 3

[0014] Take 100 parts of titanium dioxide, 1 part of potassium molybdate and 1 part of thioacetamide, and add 200 parts of distilled water. When the above system is heated and stirred to 100°C, adjust the pH to 0.5 with sulfuric acid, stir and react for 20 minutes, filter, wash and dry, calcinate the solid product in argon at 1000°C for 60 minutes, cool to room temperature, take out the sample, and obtain Molybdenum disulfide nanospheres / titanium dioxide composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com