Method for casting manganese steel broken wall or mortar-rolling wall of cone crusher by internal and external metal molds sand-lining

A technology of sand-covered metal molds and cone crushers, which is applied to casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of unstable casting quality, low dimensional accuracy of castings, and low efficiency, and achieve energy saving. The effect of shortening the production cycle and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Manufacture broken wall

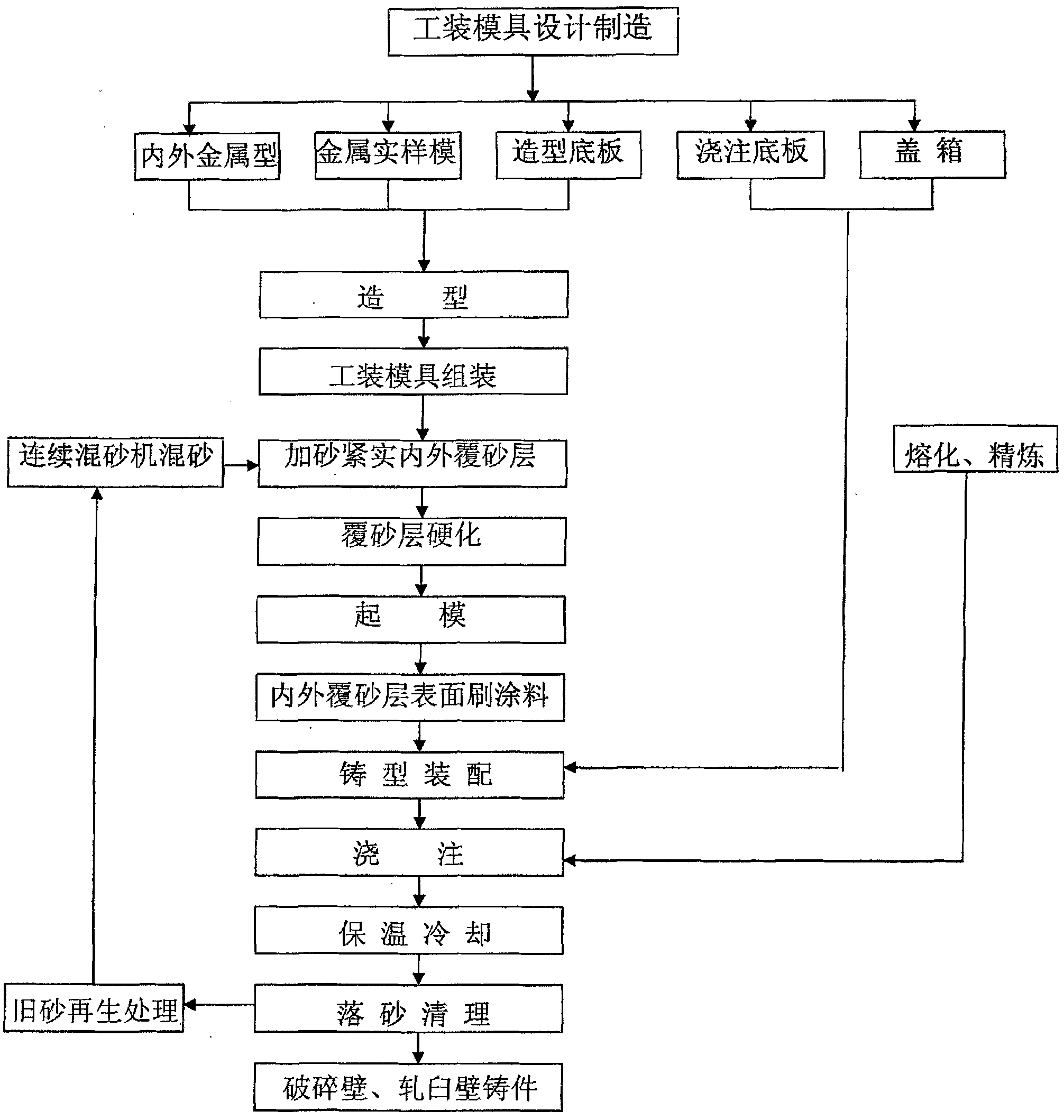

[0043] refer to figure 1 , 2 , 3, 6, its casting method steps are as follows:

[0044] 1. Tooling mold design and manufacture:

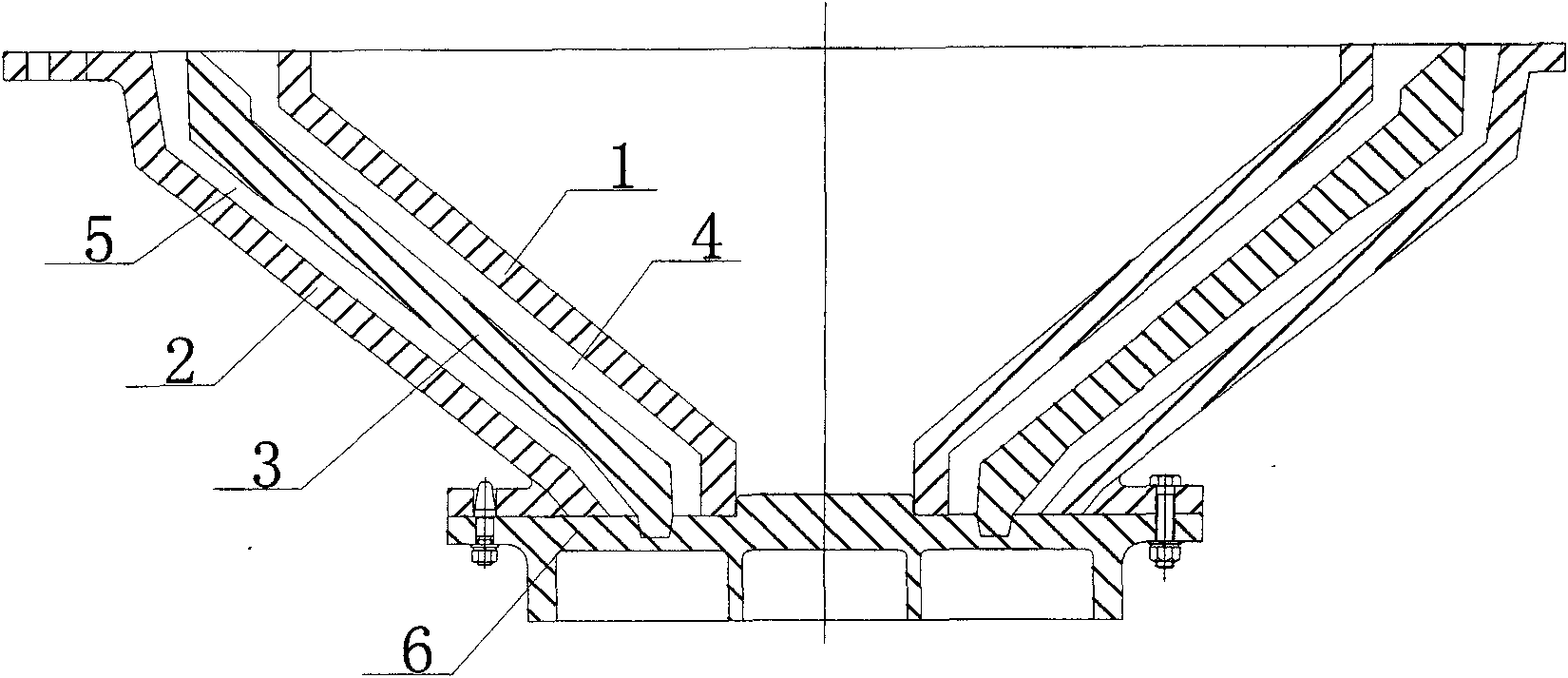

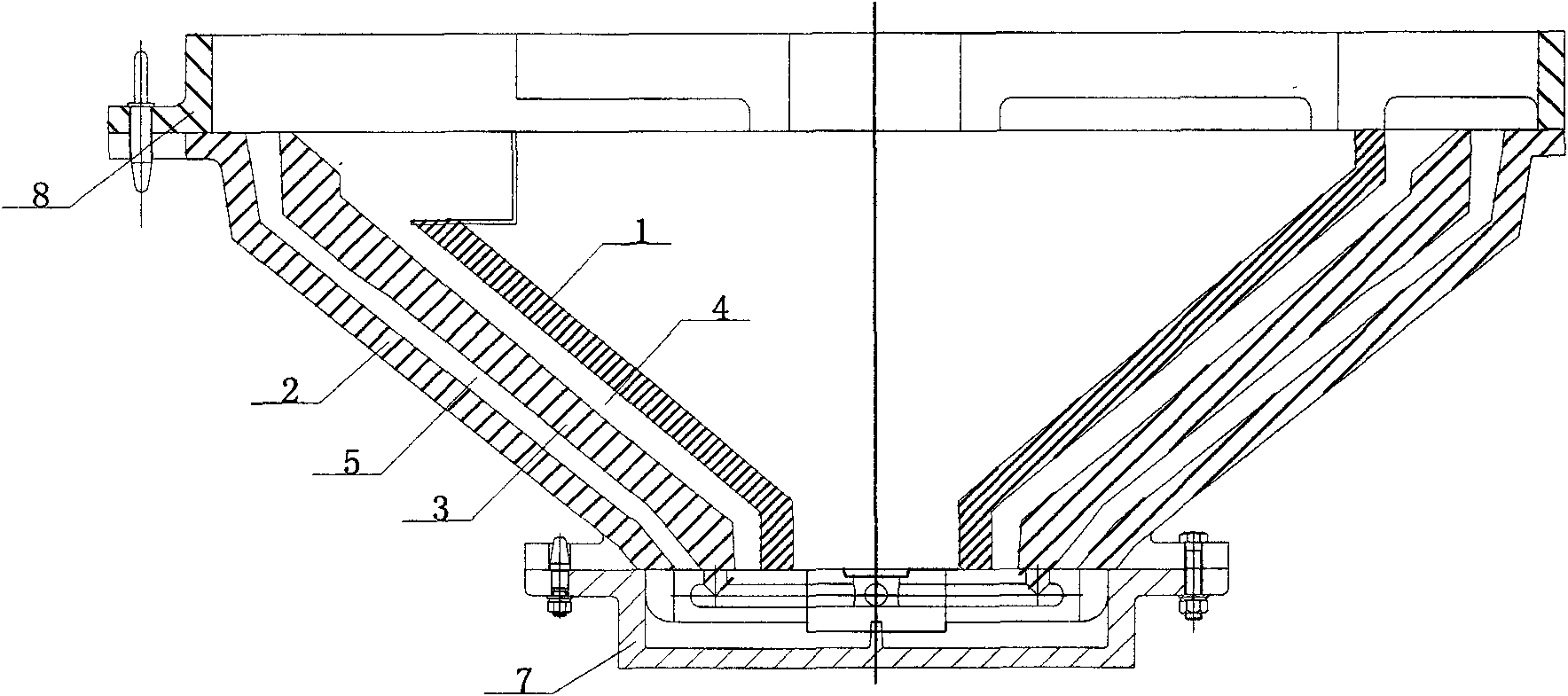

[0045] (1) Design and manufacture The near-shaped inner metal type 1 of the crushing wall is made of carbon steel, and the thickness of the near-shaped inner metal type is 20mm;

[0046] (2) Manufacturing the near-shaped inner metal type sand-covered layer 4, the thickness is 20mm;

[0047] (3) Design and manufacture The near-shape outer metal type 2 of the broken wall is made of the same material and thickness as the near-shape inner metal type 1;

[0048] (4) Manufacturing the outer metal type sand coating layer 5, the thickness is 15mm;

[0049] (5) Design and manufacture Broken wall metal real sample mold 3, the casting shrinkage rate is 2.2%, the material of the real sample mold is HT200, and the surface is smooth after machining;

[0050] (6) Design and manufacture Broken wall molding bo...

Embodiment 2

[0063] Example 2 Manufacture broken wall

[0064] refer to Figure 8 , 9 , 12, the thickness of the near-shaped inner metal type 1 is 65mm, the thickness of the near-shaped outer metal type 2 is 65mm, the thickness of the inner metal type sand-coated layer 4 is 80mm, and the thickness of the outer metal type sand-coated layer 5 is 75mm, the actual metal sample Modulo 3 is The casting shrinkage rate is 2.8%. All the other are with embodiment 1.

Embodiment 3

[0065] Example 3 Manufacture rolling wall

[0066] refer to Figure 4 , 5 , 7, its casting method steps are as follows:

[0067] 1. Tooling mold design and manufacture:

[0068] (1) Design and manufacture The inner metal mold 1 of the rolling mortar wall is close-shaped, the thickness of the metal mold is 20mm, the material is carbon steel, and the thickness of the sand-coated layer 4 of the inner metal mold is 20mm;

[0069] (2) Design and manufacture Roll the wall of the near-shaped outer metal mold 2, the thickness and material of the metal mold are the same as the near-shaped inner metal mold 1, and the thickness of the sand-coated layer 5 of the outer metal mold is 15mm;

[0070] (3) Design and manufacture The metal sample mold 3 for rolling the wall of the mortar, the shrinkage rate of the casting is 2.2%, the material of the real sample mold is HT200, and the surface is smooth after machining;

[0071] (4) Design and manufacture The molded bottom plate 6 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com