Bacillus thuringiensis microbial insecticide, preparation method and special culture medium thereof

A microbial insecticide, the technology of Bacillus aureus, applied in the field of environmental engineering, can solve the problems that Bacillus thuringiensis microbial insecticides have not yet been seen, and achieve the effect of expanding resource utilization, promoting popularization and application, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, preparation and detection of Bacillus thuringiensis microbial insecticide

[0033] One, the preparation of Bacillus thuringiensis microbial insecticide

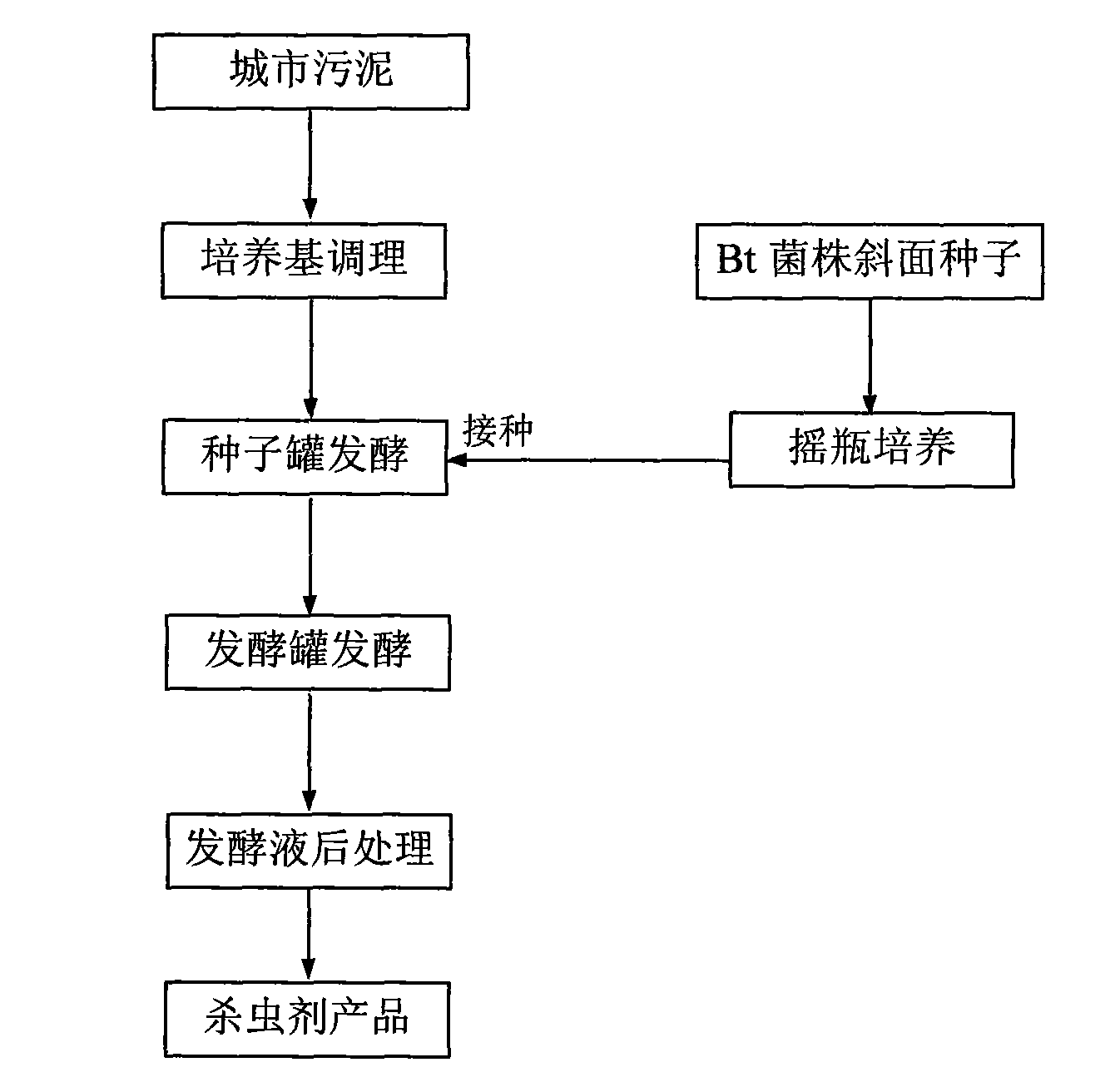

[0034] The preparation process of bacillus thuringiensis microbial insecticide is as follows figure 1 shown.

[0035] 1. Prepare culture medium

[0036] 1) Take municipal sludge samples

[0037] The mixed sludge from the sewage treatment plant was taken for experiment. The sewage treatment of the plant adopts the activated sludge method, which produces a large amount of primary sludge and residual activated sludge. After analysis, the carbohydrate content in the sludge is 104g / kgTS, the protein content is 300g / kgTS, the phosphorus content is 4g / kgTS, and the pH = 6.8.

[0038] 2) Medium conditioning

[0039] Adjust the solid content of municipal sludge to be 30g / L, add dipotassium hydrogen phosphate, magnesium sulfate, manganese sulfate and foam enemy, so that the final concentration of dipotassium hy...

Embodiment 2

[0054] Embodiment 2, preparation and detection of bacillus thuringiensis microbial insecticide

[0055] One, the preparation of Bacillus thuringiensis microbial insecticide

[0056] 1. Prepare culture medium

[0057] 1) Take municipal sludge samples

[0058] The thickened sludge from the sewage treatment plant was used for the experiment. The sewage treatment of the plant adopts the activated sludge method, and the remaining activated sludge enters the thickening tank, and the concentrated sludge is taken from the bottom of the tank. After analysis, the carbohydrate content in the sludge is 123g / kgTS, the crude protein content is 334g / kgTS, and the phosphorus content is . 7g / kgTS, pH=6.5.

[0059] 2) Medium conditioning

[0060] Adjust the solid content of municipal sludge to 20g / L, add dipotassium hydrogen phosphate, magnesium sulfate, manganese sulfate and foam enemy, so that the final concentration of dipotassium hydrogen phosphate is 0.4g / L, the final concentration of ...

Embodiment 3

[0076] Embodiment 3, preparation and detection of bacillus thuringiensis microbial insecticide

[0077] One, the preparation of Bacillus thuringiensis microbial insecticide

[0078] 1. Prepare culture medium

[0079] 1) Take municipal sludge samples

[0080] Take the remaining activated sludge from the sewage treatment plant, which uses the oxidation ditch process to treat domestic sewage. In order to ensure a higher sludge solid content, the residence time of the sludge in the sedimentation tank must be more than 10 days. After analysis, the carbohydrate content in the sludge is 150g / kgTS, the crude protein content is 380g / kgTS, the phosphorus content is 10g / kgTS, and the pH=6.7.

[0081] 2) Medium conditioning

[0082] Adjust the solid content of municipal sludge to 50g / L, add dipotassium hydrogen phosphate, magnesium sulfate, manganese sulfate and foam enemy, so that the final concentration of dipotassium hydrogen phosphate is 1.0g / L, the final concentration of magnesiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com